1. What's different between peek sheet and peek plate?

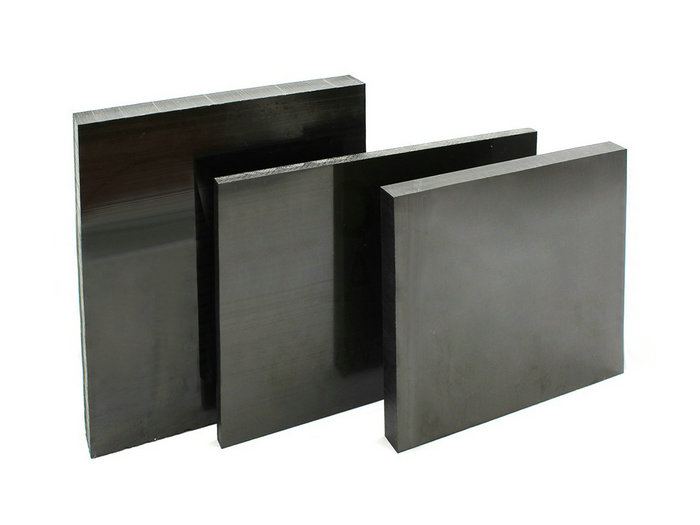

PEEK plates are typically thicker than PEEK sheets and have dimensions suitable for structural applications. PEEK sheets, on the other hand, are thinner and often used for applications that require flexibility or as protective layers.

2. What are the advantages of using PEEK sheet or PEEK plate over other plastic materials?

PEEK sheet or PEEK plate has several advantages over other plastic materials. Firstly, it has high temperature resistance and can withstand temperatures up to 250°C. This makes it suitable for applications where other plastics would melt or deform. Secondly, PEEK has excellent chemical resistance, making it ideal for use in harsh chemical environments. Thirdly, it has high mechanical strength and stiffness, making it a good choice for structural applications. Additionally, PEEK has good dimensional stability and is resistant to creep, making it suitable for use in precision applications. Finally, PEEK is biocompatible and can be sterilized, making it suitable for use in medical and pharmaceutical applications. Overall, PEEK sheet or PEEK plate offers a unique combination of properties that make it a superior choice over other plastic materials in many applications.

3. What are the typical applications of PEEK sheet or plate?

The typical applications of PEEK sheets or plates are found in a wide range of industries and fields.

In the aerospace industry, PEEK sheets and plates are used for aircraft components such as brackets, clips, and fasteners. The material's high strength and lightweight properties make it ideal for reducing weight in aircraft structures.

In the medical field, PEEK sheets and plates are commonly used for orthopedic implants, such as spinal fusion devices and joint replacements. PEEK's biocompatibility, excellent wear resistance, and ability to withstand sterilization processes make it a preferred material for medical applications.

PEEK sheets and plates also find applications in the automotive industry, where they are used for components like piston parts, bearings, and seals. The material's high temperature resistance and low friction properties make it suitable for demanding automotive environments.

In the electronics industry, PEEK sheets and plates are used for insulating components, such as circuit boards and connectors. PEEK's excellent electrical properties, including high dielectric strength and low moisture absorption, make it a reliable choice for electronic applications.

Additionally, PEEK sheets and plates are utilized in various industrial applications, including chemical processing equipment, oil and gas components, and food processing machinery. The material's resistance to chemicals, high temperature stability, and low friction properties make it well-suited for these demanding environments.

4. Can PEEK sheet or plate be machined easily?

Yes, PEEK sheets or plates can be machined easily. PEEK (Polyetheretherketone) is a high-performance thermoplastic that is known for its excellent machinability. It can be easily milled, turned, drilled, and tapped using standard machining techniques. PEEK also exhibits low moisture absorption and excellent dimensional stability, making it a popular choice for various applications in industries such as aerospace, automotive, and medical.

5. What are the limitations or challenges in machining PEEK?

Machining PEEK, although a widely used material in various industries, comes with its own set of limitations and challenges.

One of the primary challenges in machining PEEK is its high melting point. PEEK has a melting point of around 343 degrees Celsius, making it difficult to machine using conventional methods. The high temperatures generated during machining can lead to thermal degradation of the material, resulting in poor surface finish and dimensional accuracy.

Another limitation is the material's high abrasiveness. PEEK is known for its excellent wear resistance, but this property also makes it abrasive to cutting tools. The high abrasiveness can cause tool wear and reduce tool life, leading to increased machining costs.

Furthermore, PEEK has a tendency to generate heat during machining, which can cause thermal expansion and dimensional instability. This can result in part distortion and poor tolerance control.

Additionally, PEEK is a highly flexible and elastic material, which can pose challenges during machining. The material tends to deflect and deform under cutting forces, making it difficult to achieve precise and consistent cuts.

Moreover, PEEK has poor thermal conductivity, which means that heat generated during machining is not easily dissipated. This can lead to localized heating and further exacerbate the challenges associated with thermal degradation.

To overcome these limitations and challenges, special machining techniques and tools are often required when working with PEEK. For instance, using carbide or diamond-coated tools can help improve tool life and reduce wear. Coolant or lubrication techniques may also be employed to control heat generation and improve surface finish.

In conclusion, while PEEK offers excellent mechanical and chemical properties, its high melting point, abrasiveness, thermal expansion, flexibility, poor thermal conductivity, and other factors make machining this material a complex task. However, with the right techniques and tools, these challenges can be overcome to successfully machine PEEK components.