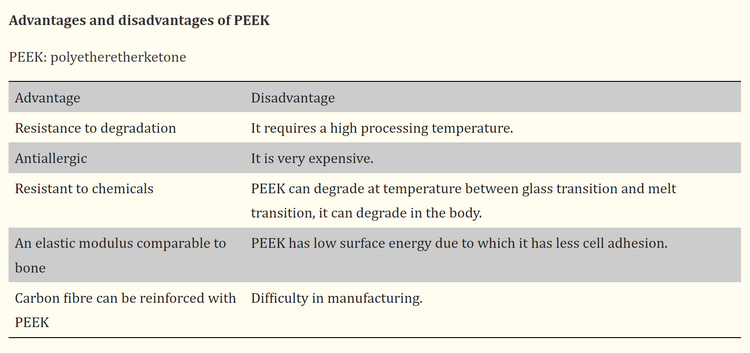

PEEK (Polyetheretherketone) is a high-performance engineering thermoplastic with a unique combination of properties, making it suitable for a variety of applications, particularly in the medical and aerospace industries. However, like any material, PEEK has both advantages and disadvantages.

Advantages of PEEK:

1, Resistance to Degradation: PEEK exhibits excellent resistance to degradation, maintaining its properties even under harsh environmental conditions, which makes it highly durable for long-term use.

2, Antiallergic: Being antiallergic, PEEK is suitable for use in medical implants and devices, minimizing the risk of allergic reactions in patients.

Resistance to Chemicals: PEEK is highly resistant to a wide range of chemicals, which makes it an ideal material for applications that involve exposure to aggressive chemical environments.

3, Elastic Modulus Comparable to Bone: The elastic modulus of PEEK is comparable to that of human bone, which makes it particularly useful in orthopedic implants where it can better mimic the mechanical properties of bone.

4, Reinforcement with Carbon Fiber: PEEK can be reinforced with carbon fiber, enhancing its mechanical properties such as stiffness and strength, making it suitable for high-performance applications.

Disadvantages of PEEK:

1, High Processing Temperature: PEEK requires a high processing temperature, which can complicate its manufacturing process and increase production costs.

2, Cost: PEEK is very expensive compared to other engineering plastics, which can limit its use to applications where its unique properties are absolutely necessary.

3, Thermal Degradation: PEEK can degrade at temperatures between its glass transition and melt transition, which can be a concern in applications involving high-temperature conditions.

4, Low Surface Energy: PEEK has low surface energy, which results in less cell adhesion. This can be a disadvantage in biomedical applications where cell integration is critical.

5, Manufacturing Difficulty: The manufacturing process of PEEK is complex and requires specialized equipment and processes, making it more challenging and costly to produce.

In summary, while PEEK offers significant advantages in terms of durability, chemical resistance, and suitability for medical applications, its high cost, manufacturing complexity, and certain limitations in high-temperature environments must be considered when choosing this material for specific applications.