Polyether Ether Ketone (PEEK) is a high-performance thermoplastic renowned for its exceptional chemical resistance, high temperature stability, and excellent mechanical properties. It is widely used in demanding applications across various industries, including medical devices, aerospace, automotive, and chemical processing. This article delves into the chemical resistance properties of PEEK, based on the data presented in two comparative tables, and highlights its performance against a variety of chemicals.

Chemical Resistance Data Overview

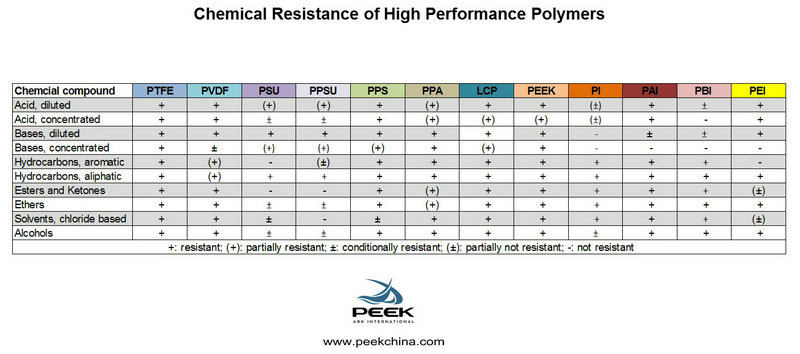

The data from the two tables illustrate the chemical resistance of PEEK in comparison to other high-performance polymers and materials, specifically PTFE, PVDF, PSU, PPSU, PPS, PPA, LCP, PI, PAI, PBI, PEI, and stainless steel (SUS316).

Table 1: Chemical Resistance of High-Performance Polymers

This table provides a comparative analysis of PEEK's resistance to different chemical compounds:

Acids (Diluted and Concentrated)

Diluted Acids: PEEK demonstrates high resistance ("+"), making it suitable for applications involving exposure to diluted acids.

Concentrated Acids: PEEK shows conditional resistance ("(±)"), indicating it can tolerate some concentrated acids but may degrade under prolonged exposure or higher concentrations.

Bases (Diluted and Concentrated)

Diluted Bases: PEEK exhibits strong resistance ("+"), suitable for environments where diluted bases are present.

Concentrated Bases: PEEK shows partial resistance ("±"), indicating limited tolerance to certain concentrated bases.

Hydrocarbons (Aromatic and Aliphatic)

Aromatic Hydrocarbons: PEEK is resistant ("+"), making it an excellent choice for applications involving aromatic hydrocarbons.

Aliphatic Hydrocarbons: PEEK also shows high resistance ("+"), suitable for exposure to aliphatic hydrocarbons.

Ethers, Esters, and Ketones

Ethers: PEEK is resistant ("+"), indicating it can withstand exposure to ethers without significant degradation.

Esters and Ketones: PEEK shows strong resistance ("+"), making it compatible with these compounds.

Solvents and Alcohols

Chloride-Based Solvents: PEEK has conditional resistance ("±"), suggesting it can tolerate certain chloride-based solvents but may be vulnerable under specific conditions.

Alcohols: PEEK demonstrates high resistance ("+"), making it suitable for applications involving alcohols.

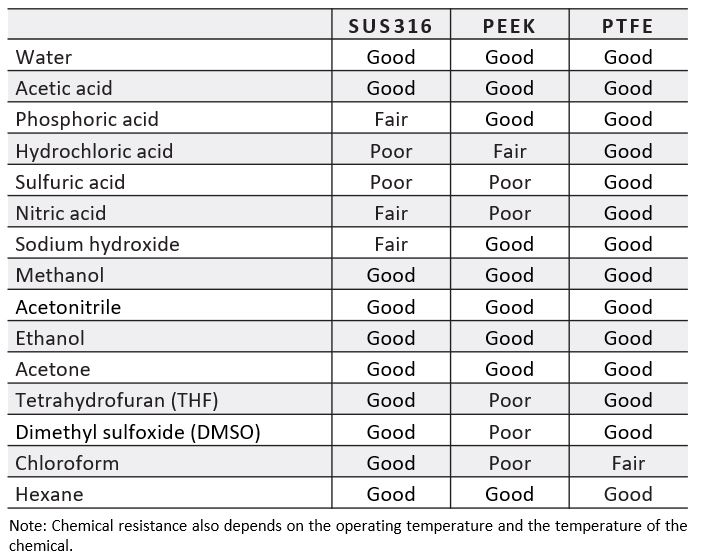

Table 2: Chemical Resistance of SUS316, PEEK, and PTFE

This table compares the resistance of PEEK to various chemicals against stainless steel (SUS316) and PTFE:

Acids

Acetic Acid: PEEK shows good resistance, suitable for applications involving acetic acid.

Phosphoric Acid: PEEK demonstrates good resistance.

Hydrochloric Acid: PEEK has fair resistance, indicating moderate tolerance.

Sulfuric Acid: PEEK shows poor resistance, unsuitable for environments with sulfuric acid.

Nitric Acid: PEEK also shows poor resistance, indicating significant vulnerability.

Bases and Solvents

Sodium Hydroxide: PEEK is resistant, making it suitable for environments with sodium hydroxide.

Methanol: PEEK shows good resistance.

Acetonitrile, Ethanol, and Acetone: PEEK demonstrates good resistance, indicating compatibility with these solvents.

Tetrahydrofuran (THF): PEEK is resistant.

Dimethyl Sulfoxide (DMSO): PEEK shows poor resistance, indicating vulnerability.

Chloroform: PEEK is resistant.

Hexane: PEEK demonstrates good resistance, suitable for exposure to hexane.

Summary and Applications

PEEK exhibits outstanding chemical resistance across a broad spectrum of environments, making it an ideal material for various high-performance applications. It is particularly effective against diluted acids, bases, hydrocarbons, ethers, esters, ketones, and alcohols. However, it has limitations in environments with concentrated acids like sulfuric and nitric acids, and solvents like DMSO.

Given its excellent chemical resistance properties, PEEK is widely used in the following applications:

Medical Devices: Due to its biocompatibility and resistance to sterilization processes.

Aerospace and Automotive: For components that require high strength and resistance to harsh chemicals and high temperatures.

Chemical Processing: For parts that must withstand aggressive chemicals and corrosive environments.

By leveraging PEEK's chemical resistance properties, engineers and designers can enhance the reliability and longevity of components in challenging conditions, ensuring optimal performance and safety.

In conclusion, PEEK stands out as a superior material for applications demanding high chemical resistance, combining robustness, durability, and versatility.