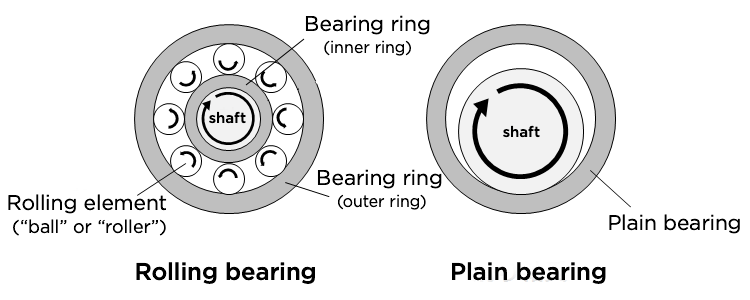

Bearings are mechanical components that support rotating parts on shafts. According to their working principles, bearings can be divided into two types: rolling friction bearings (rolling bearings) and sliding friction bearings (sliding bearings).

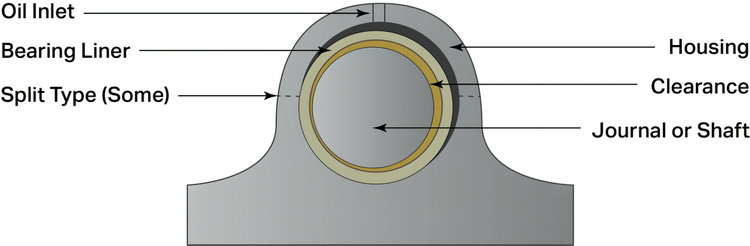

Sliding bearings have the advantages of simple structure, small radial size, strong load-bearing capacity, good shock absorption performance, stable operation, low noise, and long service life. They are widely used in various fields such as crankshafts in internal combustion engines, ship propulsion shafts, marine equipment, hydraulic machinery, and wind turbine gearboxes.

However, sliding bearings face significant starting friction resistance and it is difficult to ensure sufficient storage of lubricating oil. Under repeated heavy impact, sliding bearings are prone to interface slip, causing contact between the bearing liner and the shaft journal. This can result in peeling of the bearing lining material, fatigue abrasion on the inner surface, and lead to failures such as shaft seizure and bearing burning.

The use of self-lubricating materials in sliding bearings can effectively improve their friction and wear performance, reduce starting friction resistance, and enable normal operation in the short or long term without lubrication. Therefore, the application of self-lubricating materials in sliding bearings has become one of the current research hotspots.

PEEK is a commonly used self-lubricating material for sliding bearings, with good wear resistance, chemical stability, and dimensional stability. However, pure PEEK material used in sliding bearings faces challenges such as the need for enhanced surface adhesion, difficulty in meeting engineering requirements for wear resistance, and challenges in processing and shaping. Therefore, it is common to modify PEEK to produce PEEK composite materials with superior comprehensive performance for sliding bearings.

PEEK composite materials have low friction coefficients and low wear rates. Bearings manufactured from PEEK composite materials exhibit excellent self-lubricating properties and good temperature resistance. In addition, they have outstanding mechanical properties, fatigue resistance, corrosion resistance, lightweight characteristics, and dimensional stability. They are currently widely used in many applications.

Currently, self-lubricating sliding bearings widely use non-metallic-metal composite materials. The structure mainly consists of a matrix (steel) + liner (self-lubricating polymer), or a matrix (steel) + intermediate layer (alloy) + liner (self-lubricating polymer). PEEK, as a commonly used self-lubricating polymer material for sliding bearings, has a friction coefficient of approximately 0.48 at room temperature, a wear rate of approximately 14×10-6mm3/N·m, a melting point of about 344°C, and a glass transition temperature of about 143°C. It possesses high strength, toughness, and modulus, as well as excellent insulation, high temperature resistance, hydrolysis resistance, and radiation resistance.

Pure PEEK material faces challenges such as the need for enhanced surface adhesion, weak bonding with other materials, susceptibility to thermal expansion, thermal deformation, and thermal fatigue, as well as difficulties in processing and shaping due to poor melt flowability and high processing temperatures. To address these deficiencies, PEEK is often subjected to modification treatments to obtain PEEK composite materials with superior comprehensive performance.

The modification methods of PEEK mainly include surface modification, fiber reinforcement modification, particle filling modification, and polymer blending modification.

Surface modification involves changing the structure of PEEK material surface through chemical or physical methods to improve its friction and wear properties, thermodynamic properties, and bonding strength with other materials.

Fiber reinforcement modification involves using CF, GF, and various whiskers as fillers to modify PEEK, thus preparing PEEK composite materials with high wear resistance.

Particle filling modification aims to enhance the load-carrying capacity and transfer film strength of PEEK material by filling inorganic fillers, thereby reducing friction and wear.

Polymer blending modification involves blending PEEK with polymers with high glass transition temperatures to improve its thermal performance.

Based on practical usage, ARKPEEK has been developed into ARKPEEK-CF30 and ARKPEEK-MOD. Due to their efficient performance, they are now widely applied in specific requirements for sliding bearings. For more detailed information, please contact us.