As aerospace technology advances rapidly, there is an increasing demand for materials with lightweight, high strength, high temperature resistance, and chemical corrosion resistance. Polyetheretherketone (PEEK), as a high-performance engineering plastic, has been widely used in the aerospace field due to its excellent physical and chemical properties.

Characteristics of PEEK Material:

PEEK is a semi-crystalline polymer with the following characteristics:

1, Lightweight: Density lower than metals, contributing to reducing the weight of aircraft.

2, High strength: Comparable mechanical strength to certain metals.

3, High temperature resistance: Long-term service temperature up to 260°C, short-term tolerance up to 300°C.

4, Chemical corrosion resistance: Good resistance to most solvents and chemicals.

5, Excellent wear resistance: Outstanding performance in frictional environments.

6, Good electrical properties: Maintains stable electrical insulation performance even at high temperatures.

Applications in the Aerospace Industry

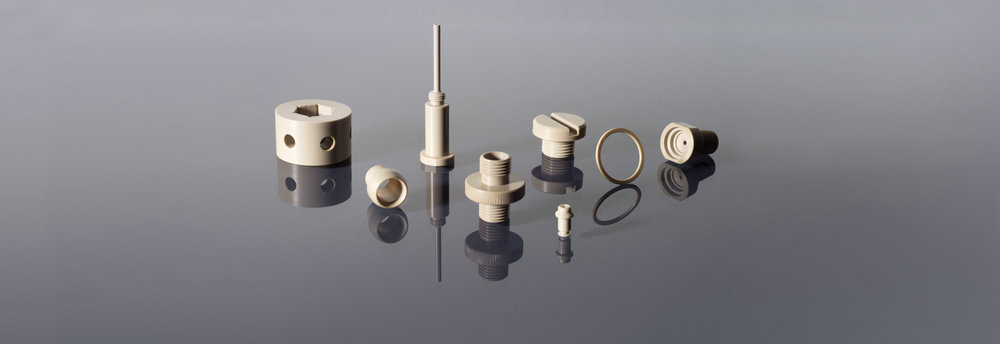

1, Structural Components

The lightweight and high-strength characteristics of PEEK material make it an ideal choice for manufacturing internal structural components of aircraft, such as seats, door components, and floor supports.

2, Engine Parts

Due to its ability to withstand high temperatures and chemical corrosion, PEEK is used in the manufacture of internal parts of aircraft engines, such as bearings, seals, and fuel system components.

3, Electronic Devices

Aerospace electronic devices require stable operation in extreme environments. PEEK's heat resistance and electrical insulation properties make it an ideal material for manufacturing circuit boards, connectors, and other electronic components.

4, Thermal Insulation Materials

PEEK's heat resistance makes it the preferred choice for manufacturing aircraft thermal insulation materials, especially in high-temperature areas near the engine.

5, Fuel Systems

PEEK's chemical corrosion resistance makes it suitable for manufacturing pipes and valves for fuel systems, which need to withstand the chemical erosion of fuel.

6, Aerospace Tools

PEEK is also used to manufacture tools, fixtures, etc., which require high wear resistance and high temperature resistance in aerospace maintenance and manufacturing processes.

Technical Challenges and Future Trends

Although PEEK has a wide range of applications in the aerospace industry, it also faces some technical challenges, such as high cost and processing difficulties. Future trends may include:

Material modification: Improve the performance of PEEK and reduce costs by adding fillers or blending modifications.

Processing technology: Develop new processing technologies to improve the processing efficiency and accuracy of PEEK materials. In recent years, the emergence of PEEK 3D printing technology has complemented the processing methods of PEEK.

Recycling: Research methods for recycling and reusing PEEK to reduce environmental impact.

Conclusion

PEEK material plays an increasingly important role in the aerospace industry due to its unique properties. With the continuous advancement of technology, the application scope of PEEK will further expand, making greater contributions to the development of the aerospace industry.