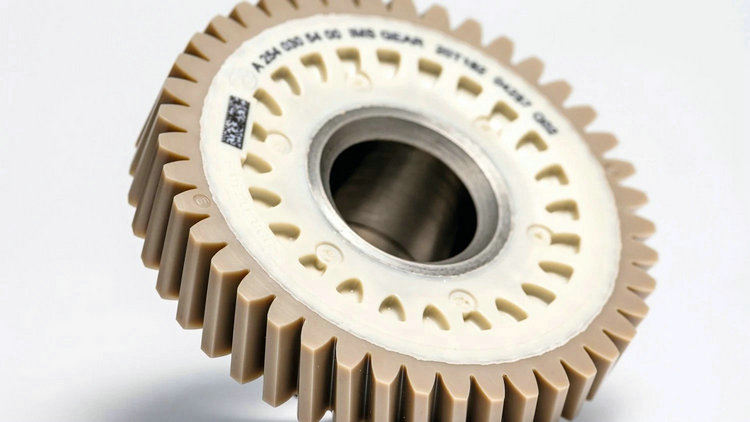

PEEK Gears: High Performance Meets Sustainability

PEEK (Polyetheretherketone) gears are increasingly recognized across industries for their exceptional performance characteristics and significant environmental benefits. With their unique material properties, PEEK gears offer superior durability, energy efficiency, and sustainability, making them an attractive choice in automotive, aerospace, medical, and industrial automation applications.

Key Performance and Environmental Benefits of PEEK Gears

1, High Temperature and Harsh Environment Resistance

PEEK gears can withstand continuous temperatures up to 260°C and maintain mechanical integrity at temperatures as high as 300°C. This makes them suitable for demanding environments like automotive engines, aerospace, and industrial machinery. Additionally, their resistance to corrosion and degradation in harsh chemical environments ensures reliable performance even in extreme conditions, reducing the need for replacements and lowering environmental impact.

2, Self-Lubricating Properties and Reduced Maintenance

One of the standout features of PEEK gears is their ability to generate a transfer film during operation, reducing friction and wear. This self-lubricating action eliminates the need for external lubrication, cutting down on maintenance requirements and operational costs. It also means that PEEK gears are ideal for applications where contamination from lubricants must be avoided, such as in food processing and medical equipment. Fewer lubricants also reduce the risk of environmental contamination.

3, Enhanced Durability and Longevity

PEEK's excellent wear resistance and low friction properties not only improve the gears' service life but also contribute to sustainability by reducing the frequency of replacements. This results in less waste and resource consumption over time, helping reduce the ecological footprint of the production process.

4, Lightweight Design for Improved Efficiency

PEEK's lightweight nature (with a density 1/5th that of steel) results in reduced overall weight for mechanical systems. This weight reduction leads to enhanced energy efficiency, particularly in sectors like automotive and aerospace, where lower mass reduces fuel consumption and carbon emissions. In machinery, lighter components also improve acceleration and deceleration efficiency, further enhancing operational performance.

5, Noise Reduction for Quieter Operations

PEEK materials absorb vibrations effectively, leading to quieter gear operation compared to traditional metal gears. This is especially advantageous in noise-sensitive applications such as office equipment, household appliances, and medical devices, contributing to a better user experience and reduced noise pollution in urban environments.

6, Chemical Resistance and Eco-Friendly

PEEK's resistance to a wide range of chemicals, including acids and alkalis, ensures it can perform in chemically aggressive environments without degrading. This property helps to prevent leaks and failures that could cause environmental contamination. Additionally, PEEK is considered non-toxic, and in the event of a fire, it produces minimal smoke and harmful emissions, making it a safer choice for both human health and the environment.

7, Sustainability and Recyclability

Beyond its durability and long lifespan, PEEK can be effectively recycled, reducing landfill waste and promoting a circular economy. The ability to reuse PEEK in various applications reduces the need for new raw materials and supports sustainability in industries that prioritize environmental responsibility.

Applications of PEEK Gears

1, Automotive Industry

PEEK gears improve the efficiency and performance of automotive components such as transmissions, engine systems (including Variable Valve Timing), and electric power steering. Their high temperature and wear resistance also reduce maintenance costs, enhancing the overall sustainability of vehicle manufacturing.

2, Aerospace

In the aerospace sector, PEEK gears are used in fuel systems, flight control mechanisms, and landing gear systems, where they offer both lightweight construction and the ability to withstand extreme operational conditions, contributing to both energy efficiency and safety.

3, Medical Devices

The biocompatibility and sterilization resistance of PEEK make it ideal for use in critical medical devices, including surgical robots, imaging systems, and dental equipment. Their durability and long lifespan help reduce waste in the medical sector while ensuring high reliability and safety.

4, Industrial Automation

PEEK gears are widely used in robotics, CNC machine tools, and automated production lines, where their self-lubricating properties, durability, and ability to handle high loads contribute to increased operational efficiency and reduced maintenance costs.

5, Electronic Equipment

In devices such as printers, copiers, and scanners, PEEK gears offer low noise operation and high precision, which enhance the performance and longevity of office equipment, reducing waste and energy consumption.

Conclusion

PEEK gears are an excellent choice for industries seeking high-performance, durable, and sustainable gear solutions. With their combination of temperature resistance, self-lubricating properties, reduced maintenance requirements, and superior wear resistance, PEEK gears outperform traditional metal gears in many demanding applications. Moreover, their environmental benefits - such as weight reduction, energy efficiency, recyclability, and reduced emissions - further establish PEEK as a material of choice for companies committed to both performance excellence and sustainability.