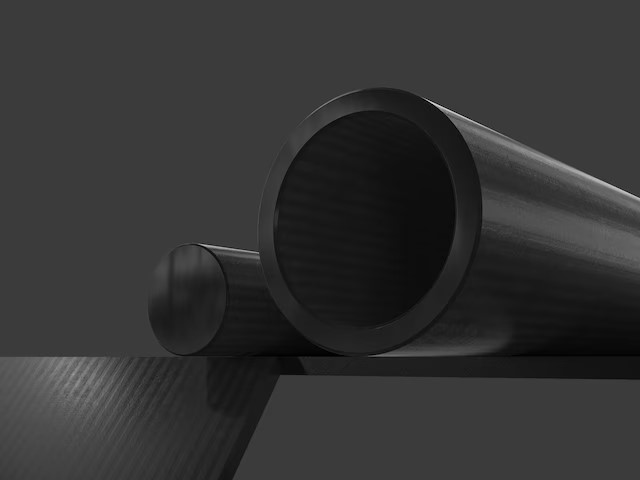

Carbon PEEK is a high-performance composite material that combines the properties of PEEK with the reinforcement of carbon fibers. This results in enhanced mechanical, thermal, and chemical properties, making it suitable for demanding applications across various industries.

Mechanical Properties

Ultimate Tensile Strength (UTS): Carbon PEEK can achieve a UTS of up to 220 MPa, which is 2 times stronger than standard PEEK and comparable to some aluminum alloys.

Tensile Modulus: The tensile modulus is significantly high, reaching up to 14 GPa, which contributes to its rigidity and brittleness.

Compressive Strength: It exhibits impressive compressive strength of about 229 MPa, making it robust under compression load.

Stiffness: Carbon PEEK is about 76% stiffer than standard PEEK, which means it deforms less under stress.

Thermal Properties

Heat Resistance: Carbon PEEK maintains structural integrity at elevated temperatures, with a maximum service temperature around 280 °C (536 °F).

Thermal Conductivity: The addition of carbon fibers enhances thermal conductivity compared to unfilled PEEK, facilitating better heat distribution and stability at high temperatures.

Coefficient of Linear Thermal Expansion (CLTE): It has a lower CLTE than standard PEEK, contributing to greater dimensional stability under temperature fluctuations.

Chemical Resistance

Carbon PEEK retains the excellent chemical resistance characteristics of PEEK, making it resistant to many organic solvents, acids, and bases even at elevated temperatures. This makes it suitable for use in chemically aggressive environments.The material's resistance extends to hydrolysis and superheated steam, enhancing its applicability in industries like automotive and aerospace where exposure to such conditions is common.

Physical Properties

Density: The density of Carbon PEEK is around 1.4 g/cm³, which is relatively low considering its high strength-to-weight ratio.

Hardness: It has a hardness rating of approximately 87 Shore D, positioning it among the tougher polymers available.

Electrical Properties: The incorporation of carbon fibers increases electrical conductivity, which can be beneficial for specific applications requiring conductive materials.

Applications

Due to its superior properties, Carbon PEEK is widely used in:

Aerospace components

Automotive parts

Medical devices

Electronics

Oil and gas industry applications

In summary, Carbon PEEK offers a unique combination of enhanced mechanical strength, thermal stability, and chemical resistance, making it an ideal choice for applications requiring high-performance materials.