Polyetheretherketone (PEEK) possesses high-temperature resistance, fatigue resistance, chemical resistance, wear resistance, hydrolysis resistance, as well as excellent mechanical properties, barrier properties, electrical properties, and radiation resistance. It has attracted widespread attention from domestic and foreign scholars, who have conducted in-depth research on the properties and modification of the material. Currently, it has been applied in mechanical, petrochemical, nuclear power, rail transportation, and biomedical materials fields.

PEEK film is an important form of PEEK, apart from its use as engineering plastics and fibers. Its main applications include vibrating membranes for electronic products, heat-insulating film layers for aircraft sound insulation and heat insulation blankets, heat-resistant insulation tapes, and flexible printed circuit boards. In this paper, a series of PEEK films were prepared by the ARKPEEK extrusion casting method. The prepared films have small thickness tolerances and high surface flatness. We conducted experiments in our laboratory to explore the basic properties, optical properties, mechanical properties, and factors affecting the mechanical properties of PEEK films, providing some basic data support for our users to further expand the application range of PEEK films.

Basic Properties of PEEK Film

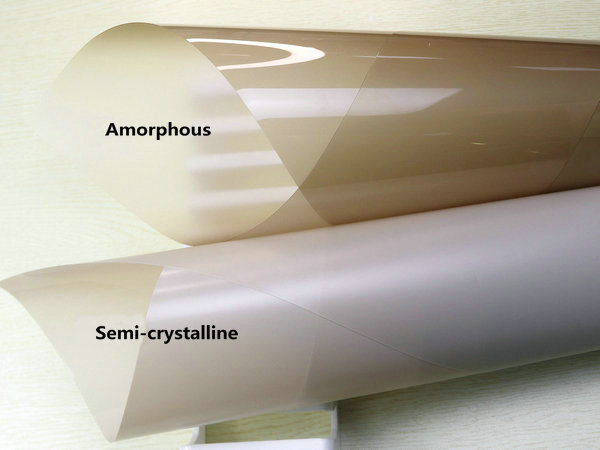

PEEK is a semi-crystalline polymer, and the transparency and physical properties of the film are closely related to the molecular chain structure of the polymer. PEEK films appear opaque brown in highly crystalline states and transparent light brown in amorphous to low crystallinity states. The image below shows a photograph of ARPEEK film.

The density of PEEK film is 1.26~1.30 g/cm³, with an amorphous density of 1.26 g/cm³. The glass transition temperature of PEEK film is 145℃, the cold crystallization peak temperature is 174℃, and the melting point is 341℃.

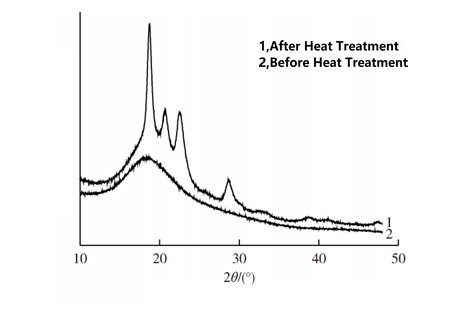

PEEK film with a transmittance of 84.6% and a thickness of 95μm was subjected to heat treatment at 250℃ for 20 minutes. The figure below shows the wide-angle XRD spectra of PEEK film before and after heat treatment. PEEK belongs to the orthorhombic crystal system. Before heat treatment, the crystallinity of the film is low. After heat treatment, PEEK film exhibits four main diffraction peaks at 18.7°, 20.6°, 22.6°, and 28.6°, corresponding to the 110, 111, 200, 211, and 202 directions, respectively. The peaks of the 211 and 202 directions overlap. The test data is consistent with literature reports. Due to PEEK being a semi-crystalline polymer, the amorphous regions contribute to a higher diffraction peak background.

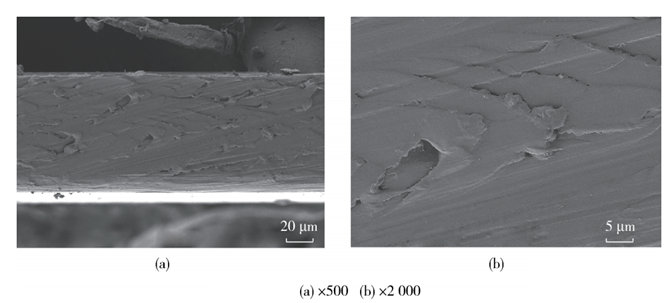

The figure below shows the SEM photograph of the cross-sectional structure of PEEK film. PEEK film can maintain high toughness in liquid nitrogen. PEEK film prepared by extrusion casting method has a roller temperature higher than the glass transition temperature of PEEK. Since the casting roller has a certain speed, the film undergoes a certain amount of stretching in the longitudinal direction. From the figure, the longitudinal cross-section of the film can be observed, where the polymer molecular chains exhibit high orientation along the stretching direction.

Relationship between Film Crystallinity and Transmittance

The temperature and speed of the casting roller directly affect the structure, morphology, and thickness of the film. When the film thickness is the same, higher crystallinity leads to lower transmittance.

The haze of the film can also reflect the color state of the film. Higher crystallinity results in increased haze values. When the crystallinity is below 5%, the film exhibits high transparency and clarity. Below it's picture from ARKPEEK which shows it well.

Amorphous is low crystallinity and Semi-crystalline is higher.

Analysis of Mechanical Properties of Extruded Films

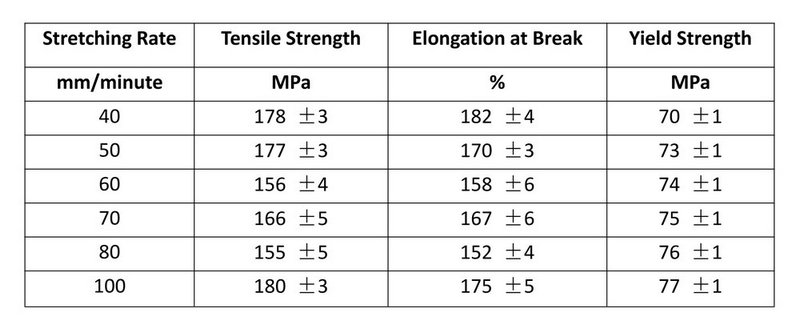

Due to the lack of national standards for PEEK films in China, there is no uniform method for tensile testing of PEEK films in academic literature. It is necessary to investigate the influence of tensile rate on the mechanical properties of the films. Our study involved testing 18μm PEEK extruded films, with tensile rates ranging from 40 to 100 mm/min, as shown in the experimental results in the table below.

The tensile strength and elongation at break show similarities, indicating that the tensile rate has minimal influence on them. However, increasing the tensile rate significantly enhances the yield strength. Even at a tensile rate of 100 mm/min, the film still exhibits relatively high tensile strength. This study evaluates the mechanical properties of PEEK film at a tensile speed of 100 mm/min.

Analysis of Surface Defects and Mechanical Properties of Films

The die head is a critical factor affecting the surface quality of the film. Inadequate cleaning of the screw and die head can affect the surface of PEEK film. After shutdown of the extruder, restarting it without thorough cleaning leads to difficulties in flushing out the PEEK material, resulting in more charred residues and gel points on the film, which affects its surface quality and performance. While gel points and charred residues impact the surface quality, a small amount of gel points has minimal effect on the mechanical properties of the film.

Analysis of Film's UV Resistance

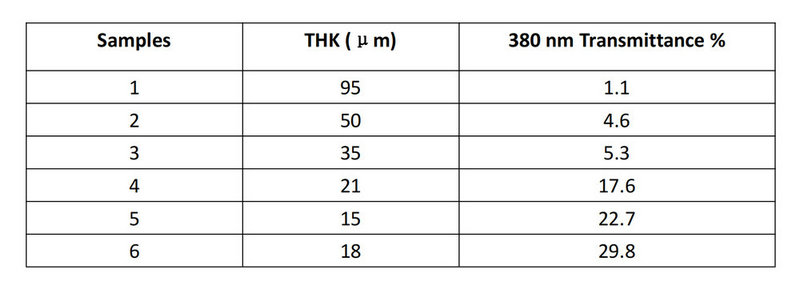

Through testing in the ARKPEEK laboratory, we obtained the following data on the relationship between the transmittance of 380nm ultraviolet light and film thickness. It's evident that with increasing film thickness, the transmittance of UV light at 360-380 nm decreases, indicating better UV resistance.

Relationship between UV Transmittance and Film Thickness

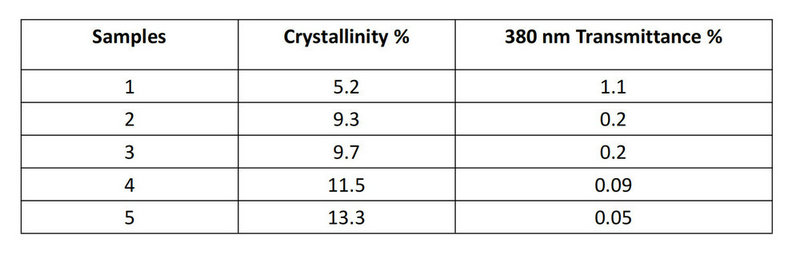

We also studied the ultraviolet transmittance spectra of PEEK films with the same thickness but different crystallinity. There is a slight difference in the transmittance of 380nm ultraviolet light, with better UV resistance observed in films with higher crystallinity. Specific data can be found in the figure below.

Relationship between UV Transmittance and Crystallinity

In summary, the conclusions are as follows:

(1) The transmittance of PEEK film decreases with increasing crystallinity. The effect of tensile rate on tensile strength and elongation at break is minimal, with a faster tensile rate leading to a significant increase in yield strength. Tensile strength increases with increasing extrusion roller speed. PEEK exhibits stable mechanical properties when extruded at 390~400°C, and even at an extrusion temperature of 420°C, PEEK film can maintain relatively high mechanical strength.

(2) Biaxial stretching after extrusion can greatly increase the tensile strength of PEEK film. With a stretching ratio of longitudinal × transverse = 2 × 2, the longitudinal tensile strength can reach 203 MPa, with an elongation at break of 76%, while the transverse tensile strength is 157 MPa, with an elongation at break of 156%.

(3) PEEK film exhibits UV resistance characteristics. With increased film thickness and crystallinity, the transmittance of UV light at 360~380 nm decreases, indicating better UV resistance.