Polyether Ether Ketone, commonly known as PEEK, is a high-performance engineering thermoplastic that stands out for its exceptional mechanical properties. Used in a wide range of industries such as aerospace, automotive, medical, and electronics, PEEK is valued for its strength, durability, and resistance to extreme conditions.

Below FAQ section addresses the most common questions about PEEK's mechanical properties, providing insights into why this material is often the preferred choice for critical applications. Whether you're an engineer, designer, or material scientist, these answers will help you understand the key benefits and applications of PEEK.

What are PEEK material properties?

About PEEK. PEEK (polyetheretherketone) is a high-performance engineering plastic with outstanding resistance to harsh chemicals, and excellent mechanical strength and dimensional stability. It offers hydrolysis resistance to steam, water, and sea water.

What are the mechanical properties of PEEK?

Very high Young's Modulus (3600-4200 MPa), very high strength (approx. 100 MPa), with glass or carbon fiber much higher. Very good ductility and excellent wear permanence, especially in specifically developed composites.

What is the hardness of PEEK material?

For the unfilled PEEK, the hardness is 29.24 HV

How durable is PEEK?

PEEK is an incredibly durable and versatile high-performance plastic for demanding and challenging industrial applications that require parts that can withstand high temperatures, high pressure, high impact, corrosion and friction or wear.

Why is PEEK so strong?

PEEK stands for “polyetheretherketone”, making it part of the broader family of ketone polymers. The unique chemical structure of this thermoplastic makes it incredibly strong and dimensionally stable both under load and in the harshest environments.

Is PEEK strong or weak?

PEEK is a high-performance engineering plastic with outstanding resistance to harsh chemicals, and excellent mechanical strength and dimensional stability.

Is PEEK bendable?

PEEK is a stiff material but can still exhibit flexibility comparable to other plastics (but this will depend heavily on the specific PEEK grade). PEEK has a flexural modulus most like human cortical bone and, combined with its biocompatibility, makes PEEK ideal for medical implants and devices.

Is PEEK good for bearings?

PEEK bearings can provide exceptional performance in high ambient temperatures and with low-viscosity lubricants such as water. It is also an electrical insulator and resistant to chemical attack.

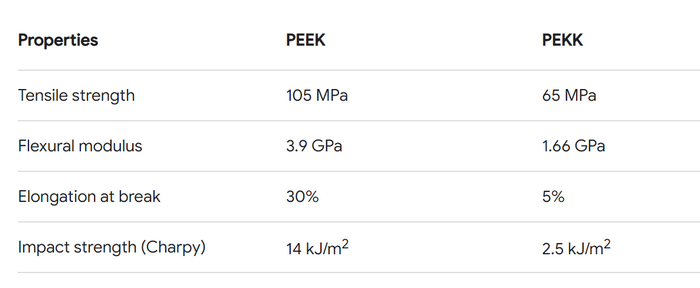

What are the mechanical properties of PEEK vs pekk?

For specific datasheet, pls visit ARKPEEK Properties.