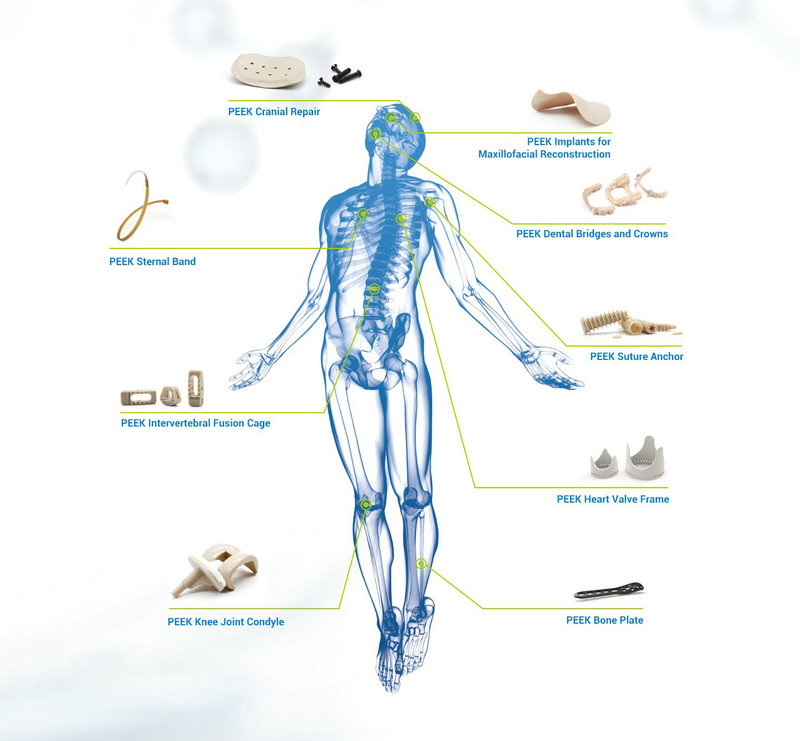

It is well-known that the human body has very high requirements for implant materials. For a long time, metals have been the material of choice for implants. As early as the 16th century, thin sheets of pure gold were used to repair cranial defects. In recent years, with the rapid development of material science, medical polymer materials have gradually become the most widely used and largest-volume materials. PEEK (Polyether Ether Ketone), as a new type of medical implant material, has stood out among many medical materials due to its excellent properties and is increasingly used in fields such as orthopedics, cardiovascular surgery, and artificial spines.

1. Excellent Performance: The Material Closest to Bone

Biocompatibility is the most basic factor in determining whether a material is suitable for human implantation. The material must be non-toxic, non-mutagenic, non-carcinogenic, and non-allergenic. Implant-grade PEEK has undergone comprehensive biocompatibility tests at independent foreign testing institutions in strict accordance with ISO 10993 standards. The results show that implant-grade PEEK has excellent biocompatibility with no adverse effects.

The famous Wolff's Law states that bone grows where needed and is absorbed where not needed, meaning that bone growth, absorption, and remodeling are all related to the stress state of the bone. Since the elastic modulus of metals is much higher than that of bone, when metal is implanted in the body, it takes on most of the mechanical load, reducing the load on the bone and creating a stress shielding effect. This delays bone healing, and over time, the bone becomes porous or even degenerates. In contrast, PEEK's elastic modulus is very close to that of bone, allowing the bone to bear more stress, keeping it healthier.

In addition, compared to metals, PEEK is radiolucent, providing good visibility in X-rays. X-rays show no artifacts, allowing surgeries to be performed under CT or MRI assistance, helping doctors adjust the implant's position during surgery and easily track the healing process post-operation, effectively monitoring bone growth and healing.

2. Skull Repair: Avoiding the Embarrassment of Cold Winters and Hot Summers

To better restore the integrity of the skull and effectively protect brain tissue, neurosurgical researchers have long sought a material that more closely resembles the skull for repairs. Researchers have found that PEEK is currently the clinical skull repair material with properties most similar to human bone.

Compared to commonly used titanium alloys, PEEK's physical properties are closer to human bone. It is sturdy and avoids the risk of deformation under pressure. Its thermal insulation properties help avoid the discomfort of cold winters and hot summers. While titanium alloys conduct heat well, this becomes a drawback for patients. When exposed to external temperature changes, the environment inside the skull changes, affecting comfort. For example, in winter, when a patient moves from a warm indoor space to a cold outdoor environment, the excellent thermal conductivity of the titanium skull plate can cause discomfort or pain. PEEK's thermal insulation properties avoid the discomfort associated with titanium alloy mesh in hot and cold weather.

The Gansu Provincial Hospital successfully used PEEK in a skull defect repair surgery. According to Yang Youwen, the director of the hospital’s neurosurgery department, PEEK overcomes the disadvantages of conventional skull repair materials such as acrylic, bone cement, and titanium alloy, which often result in strong rejection, poor shaping effects, poor insulation, and discomfort, as well as poor postoperative X-ray transparency. It also avoids the discomfort caused by temperature changes. With 3D printing technology, PEEK can be molded to fit perfectly, providing excellent biocompatibility, and its mechanical properties are similar to human bone. It is expected that this new material will become the preferred material for skull repair surgeries.

3. Spinal Repair: Reducing the Occurrence of Complications

In recent years, the incidence of lumbar and cervical spine diseases in China has been increasing year by year, and it is becoming more prevalent among younger people. The number of patients with lumbar diseases has exceeded 200 million, and there are also 200 million patients with cervical spine issues. If a patient has degenerative spinal disease, doctors will recommend removing the diseased intervertebral disc and implanting a device called an "interbody fusion cage" as a replacement.

A fusion cage provides a bony connection between adjacent vertebrae to treat chronic back pain caused by disc disease or spinal instability. In September 1996, the U.S. FDA officially approved the use of spinal interbody fusion cages for lumbar fusion surgery. China introduced artificial disc replacement surgery around 2003.

Currently, the most common types of interbody fusion cages in China are made from titanium alloys or PEEK. Due to the high elastic modulus of titanium alloys, postoperative stress shielding often causes delayed fusion, leading to the increasing use of PEEK fusion cages in recent years. PEEK interbody fusion cages are compatible with X-ray imaging and MRI, and their low elastic modulus avoids complications with autografts and defects with allografts.

Dr. Shang Peng from the Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences, explained that modified PEEK has even stronger performance. By cross-linking with type I collagen, the surface hydrophilicity and cell adhesion properties of PEEK can be improved, making the modified material have better biocompatibility and bone fusion ability than unmodified materials.

4. Fracture Treatment: Reducing the Probability of Refracture

In 1895, metal plates were first used for internal fixation in fracture treatment, but corrosion was a problem. While the introduction of stainless steel resolved this issue, the stress shielding effect became a concern. High-elastic modulus metal plates block the necessary external stresses, leading to weak and porous bone. When the plate is removed and the healed bone is subjected to weight-bearing stress, it cannot adapt to the changing stress environment and is prone to refracture. PEEK, on the other hand, exhibits better bending fatigue strength, is unaffected by pre-treatment and thermoforming, and has good tissue compatibility, allowing the fixation plate to fit more accurately onto the patient's bone.

Additionally, PEEK suture anchors are widely used in sports medicine, mainly for treating rotator cuff or ligament tears and other joint injuries. Traditional metal anchors can cause complications such as loosening, pull-out, and cartilage damage, while the introduction of high-strength sutures increases the load on the suture anchor junction, raising the risk of cutting at the junction. PEEK suture anchors avoid these problems. Compared to absorbable anchors, PEEK has higher strength and X-ray transparency, ensuring no metallic artifacts in postoperative imaging, while its elastic modulus is between cortical and cancellous bone, reducing stress shielding and promoting bone healing.

5. Dental Implants: Providing More Comfort to Patients

Due to its excellent chemical stability and resistance to most chemical reagents, PEEK is increasingly used in dental medicine. PEEK materials are primarily applied to components of dental implants, such as temporary abutments, healing caps, and healing abutments. Compared to commonly used materials like metal, zirconia, and alumina, PEEK does not require sintering, making it more precise; its low density and lightweight nature provide more comfort for patients. The material's softness acts as a cushion, reducing shock during biting.

Disadvantages of PEEK as a Medical Implant:

1. Complex Manufacturing - The manufacturing process of PEEK is relatively complex, requiring high temperature and high pressure, which can increase production costs.

2. High Cost - Compared to other materials, such as titanium alloys, PEEK is more expensive, which may affect the overall cost of surgery.

3. Low Clinical Adoption Rate - Since PEEK has been introduced later in the medical field, its clinical use rate is still low. Doctors are more accustomed to using titanium materials, so PEEK's clinical application is not yet widespread. More clinical experience and knowledge sharing are needed for broader adoption.