Polyether ether ketone, or PEEK for short, is a high-performance thermoplastic material that has become increasingly popular in a variety of industries.

Its unique properties make it an ideal choice for a wide range of applications, from medical implants to aerospace components.

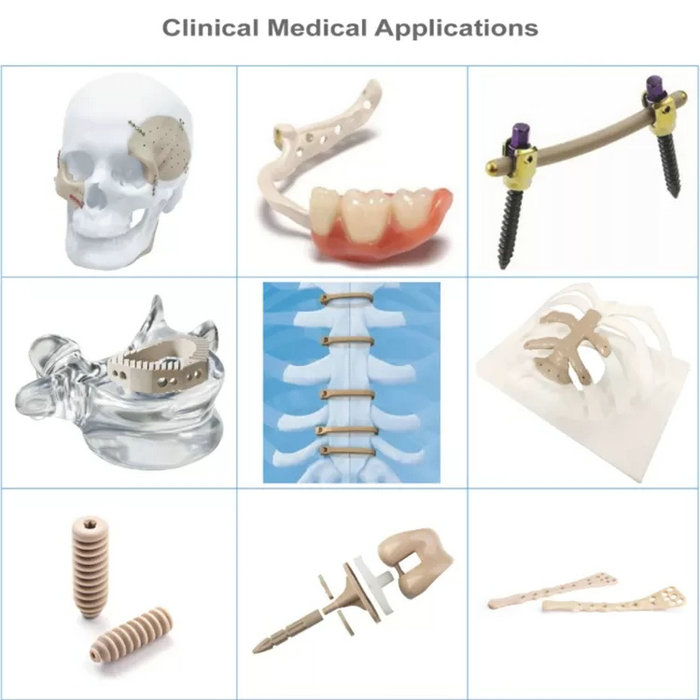

One of the most common uses of PEEK is in the medical industry, where it is often used to manufacture implantable medical devices.

These devices can include everything from spinal implants to dental implants to joint replacements.

The reason PEEK is such a popular choice for these applications is that it is biocompatible, meaning it does not cause an adverse reaction within the body.

In addition to its biocompatibility, PEEK is also highly resistant to wear and tear, making it an ideal material for use in medical devices that will be

subjected to constant use and stress. It is also highly resistant to chemicals and radiation, which makes it an ideal choice for use in medical imaging

equipment.

Industrial PEEK, on the other hand, is used in a wide range of industrial applications. It is often used in the manufacturing of components for the

aerospace and automotive industries, as well as in the oil and gas industry. The reason PEEK is such a popular choice for these applications is that

it is highly resistant to high temperatures and chemicals, making it an ideal choice for use in harsh environments.

One of the key differences between medical PEEK and industrial PEEK is the way in which they are manufactured. Medical PEEK is often manufactured

using a process known as implant-grade PEEK, which involves strict quality control measures to ensure the material meets strict medical standards.

Industrial PEEK, on the other hand, is often manufactured using a less stringent process that focuses more on cost-effectiveness than on quality control.

Another key difference between medical PEEK and industrial PEEK is the way in which they are used. Medical PEEK is primarily used in implantable

medical devices, while industrial PEEK is used in a wide range of industrial applications.

In terms of cost, medical PEEK is typically more expensive than industrial PEEK due to the strict quality control measures that are in place during

the manufacturing process. However, when it comes to medical devices that will be implanted within the body, cost is often not the most important factor.

Instead, factors such as biocompatibility and wear resistance are much more important.

In summary, while medical PEEK and industrial PEEK are both made from the same material, there are some key differences between the two.

Medical PEEK is manufactured using a strict quality control process and is primarily used in implantable medical devices due to its biocompatibility

and wear resistance. Industrial PEEK, on the other hand, is used in a wide range of industrial applications due to its high resistance to high temperatures

and chemicals.