Polyether ether ketone (PEEK) is a high-performance engineering plastic that has gained widespread use across aerospace, automotive, electronics, and other industries. As motor technology evolves, the potential for PEEK in motor applications is being increasingly recognized—especially in environments requiring high temperature resistance, high speed, heavy loads, and superior electrical insulation.

Bearing Cages

PEEK can replace metal or nylon in bearing cages to address micro-motion wear issues during high-speed operation.

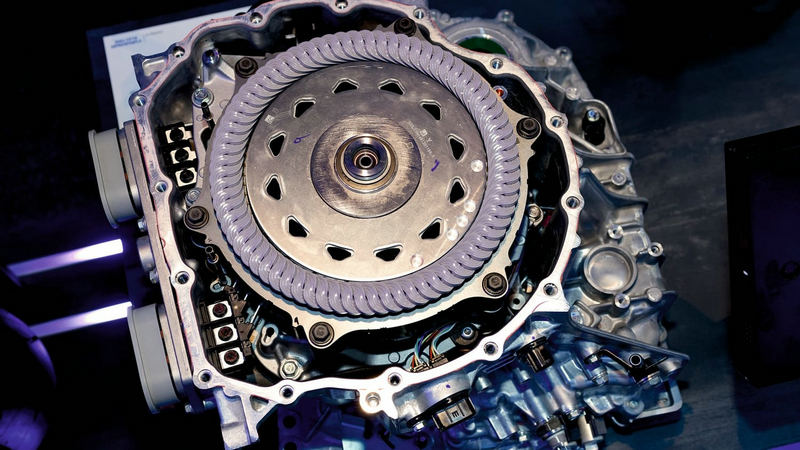

PEEK Rotors

PEEK rotors provide an ideal combination of strength, temperature resistance, and lightweight design, suitable for high-performance motor applications.

Gear Transmission Components

PEEK gears, such as those in assemblies like Ce ASE - BALRATA, offer smooth, low-noise performance and excellent durability under mechanical stress.

Carbon Fiber Reinforced PEEK Rotors

Reinforced PEEK composites enhance stiffness and dimensional stability, making them ideal for precision motor rotors in demanding environments.

Enameled PEEK Wire

Enameled PEEK wire uses PEEK as a single-layer extruded insulation around the conductor. Compared to traditional enameled wires (like polyester or polyimide), PEEK wire has a thinner, more uniform insulation layer. It excels in high-temperature, corona-resistant, and chemically corrosive environments.

PEEK Film for Slot Insulation

In motor slot insulation, PEEK film outperforms traditional composite paper. It helps manufacturers improve copper fill factor and optimize thermal management.

High-Temperature Resistance

PEEK maintains stable physical and chemical properties even under continuous exposure to temperatures up to 250°C.

Mechanical Strength and Wear Resistance

Its high strength and excellent wear resistance help reduce wear and extend service life, especially in high-load motor components.

Electrical Insulation

As a non-conductive material, PEEK offers excellent electrical insulation—ideal for high-voltage motor systems where safety and stability are paramount.

Chemical Stability

PEEK resists corrosion from most chemicals, making it highly reliable in humid or chemically aggressive environments, such as marine and chemical industry motors.

High Cost

PEEK is significantly more expensive than metals or conventional plastics, which limits its use in cost-sensitive applications.

Processing Complexity

Its high melting point and mechanical strength require advanced tools and techniques for cutting, molding, and welding.

Durability and Aging

Though highly durable, prolonged exposure to high temperatures, oxygen, and humidity may lead to gradual degradation in mechanical performance.

Design and Engineering Compatibility

Motor designs must be adapted to accommodate PEEK’s unique material properties. Engineers must optimize component structures to leverage its strengths effectively.

PEEK material presents excellent potential for motor applications, particularly in high-performance environments such as aerospace, defense, and advanced industrial systems. As technology progresses and material costs are managed more efficiently, PEEK is expected to play an increasingly vital role in the evolution of motor design and manufacturing.