PEEK (Polyether Ether Ketone) is a high-performance engineering plastic known for its excellent mechanical properties, chemical resistance, heat resistance, and self-lubricating properties. In the valve industry, the application of PEEK material is becoming increasingly widespread, mainly due to its reliability and durability under extreme working conditions.

Characteristics of PEEK Material

Chemical Resistance: PEEK has an extremely high resistance to most solvents, chemicals, and radiation, making it perform excellently in valve applications in the chemical and pharmaceutical industries.

Heat Resistance: PEEK can continuously operate at temperatures up to 250°C, making it suitable for controlling high-temperature fluids.

Mechanical Strength: PEEK has high tensile strength and impact resistance, maintaining these properties even at low temperatures.

Self-Lubricating: PEEK's self-lubricating properties reduce friction and wear in the moving parts of valves, extending the valve's lifespan.

Hydrolysis Resistance: The stability of PEEK in water and steam makes it an ideal valve material for water treatment and steam systems.

Applications of PEEK in Valves

Chemical Valves: In the chemical industry, PEEK valves can withstand the corrosion of strong acids, bases, and other corrosive chemicals.

Medical Devices: Due to its biocompatibility and resistance to sterilization, PEEK is used in valves for medical devices such as infusion pumps and dialysis machines.

Aerospace: PEEK's lightweight and high-temperature resistance make it an ideal choice for valves in the aerospace sector.

Food Processing: PEEK valves are used in the food processing industry to handle high-temperature, high-pressure, and potentially corrosive food ingredients.

Semiconductor Manufacturing: In the semiconductor industry, PEEK valves are used to control the flow of high-purity gases and chemicals.

Design ConsiderationsWhen designing PEEK valves, the following key factors need to be considered:

Temperature Range: Select the appropriate grade of PEEK based on the application environment to ensure performance at extreme temperatures.

Pressure Rating: The design of PEEK valves must withstand the expected working pressure.

Chemical Compatibility: Choose the correct PEEK formulation based on the chemical properties of the fluid to ensure long-term stability.

Dimensional Stability: The dimensional changes of PEEK at different temperatures need to be considered in the design to avoid valve leakage or damage.

Manufacturing ProcessThe manufacturing of PEEK valves typically involves the following steps:

Material Selection: Choose the appropriate grade of PEEK based on application needs.

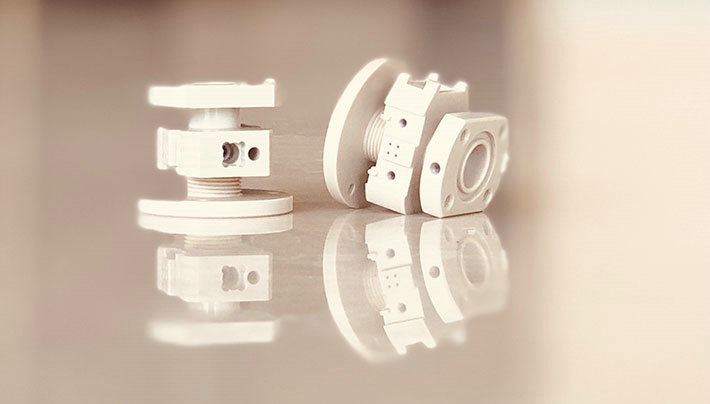

Molding Process: Manufacture the valve components using injection molding, compression molding, or extrusion.

Assembly: Assemble the molded components into a complete valve, ensuring all connections are firm and sealed.

Testing: Perform pressure and chemical compatibility tests on the valve to ensure it meets performance standards.

Conclusion

The application of PEEK material in valve manufacturing provides a high-performance, reliable, and durable solution. With technological advancements and the development of new materials, we can expect the application of PEEK in the valve industry to continue to expand, providing innovative fluid control solutions for more industries.

What is PEEK in valve?

PEEK (polyether ketone) is an outstanding high-performance semi-crystalline engineering thermoplastic with exceptional resistance to harsh chemicals, deficient moisture absorption, good fire performance, excellent mechanical strength, and dimensional stability in a range of environments.

What is the temperature rating for PEEK valve seats?

-70°F to 600°F / -73°C to 298°C.

PEEK Ball Valve Seats. PEEK has much in common with PTFE, including an extensive temperature range from -70°F to 600°F, and good chemical compatibility.