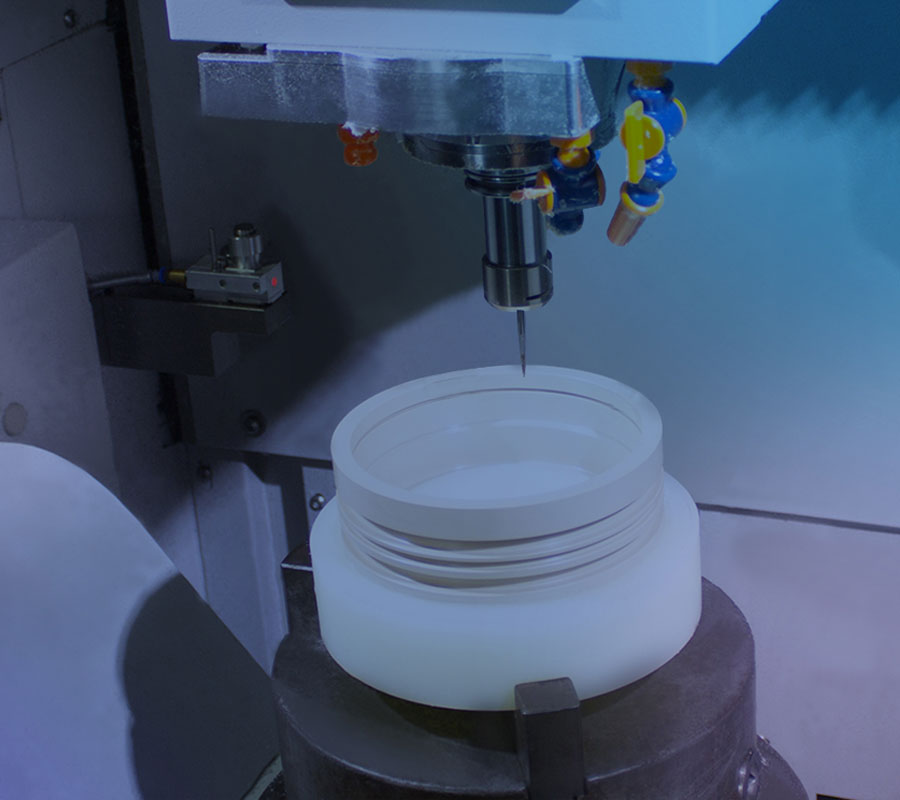

When it comes to crafting precision parts using CNC machining, selecting the right material is like choosing the perfect tool for an intricate job. Among the diverse materials available, polyether ether ketone, or simply PEEK, is a standout performer. In this article, we'll dive into the fascinating world of PEEK and explore the scenarios where it truly shines in CNC machining.

1. Conquering the Heat

Imagine needing a part that can endure blistering temperatures without breaking a sweat. PEEK can do that. With an impressive tolerance for continuous temperatures reaching up to 480°F (250°C), PEEK is your go-to material when the heat is on. This makes it ideal for crafting components for aerospace, automotive engines, and industrial machinery that operate in scorching environments.

2. Battling Chemical Challenges

In the world of CNC machining, certain industries are akin to chemical battlefields. PEEK steps in as the unyielding warrior, immune to the corrosive forces of harsh chemicals. Whether it's the chemical sector, oil and gas industry, or pharmaceuticals, PEEK's ability to withstand chemical aggression and remain compatible is a game-changer.

3. Lightweight, Yet Mighty

Strength without the weight – that's the PEEK advantage. With a strength-to-weight ratio comparable to some metals, PEEK is the top choice when you need lightweight components without compromising on durability. It's like having the perfect sidekick for aerospace innovations, groundbreaking medical devices, and more.

4. Healing with Biocompatibility

When it comes to medical applications, biocompatibility is non-negotiable. PEEK gets a resounding endorsement from the FDA for its exceptional biocompatibility. This makes it a natural fit for CNC machined medical devices and implants, ensuring patient safety and health.

5. Electrical Insulation Expertise

In the world of electronics, where electrical insulation is paramount, PEEK rises as the undisputed expert. It acts as a formidable shield against high voltages and maintains its electrical properties over time. Whether you're designing insulators, connectors, or protective housings, PEEK has your back.

6. The Friction Fighter

Imagine a world where friction is no longer a hindrance. PEEK turns this into a reality with its low coefficient of friction. This property extends the lifespan of critical components in industries like automotive, aerospace, and manufacturing, where friction can wear things down.

7. The Dimensional Dynamo

Precision matters in CNC machining, and PEEK brings it in spades. Its exceptional dimensional stability, even in fluctuating conditions, ensures your meticulously crafted parts maintain their form and measurements. No surprises here; it's all about consistency.

So, when you find yourself in the world of CNC machining, facing challenges like high temperatures, chemical onslaughts, the need for lightweight yet robust components, or biocompatibility requirements, remember PEEK. It's not just another material; it's a trusted ally in achieving excellence. PEEK elevates your CNC machined parts to new heights, showcasing the finesse of precision engineering.