Abstract

With the rapid development of semiconductor technology, the requirements for materials in wafer manufacturing are becoming increasingly stringent. PEEK (polyether ether ketone), a high-performance engineering plastic, is being increasingly utilized in wafer manufacturing. Its excellent physical, chemical, and mechanical properties make it an indispensable material in this field.

Introduction

In the heart of the semiconductor industry, wafer manufacturing, the choice of materials is crucial. PEEK material, with its outstanding properties such as high temperature resistance, chemical corrosion resistance, wear resistance, dimensional stability, and antistatic properties, plays an important role in various stages of wafer manufacturing.

Overview of PEEK Material

PEEK is a special engineering plastic composed of aromatic rings and ether bonds, possessing excellent thermal stability and mechanical strength. PEEK's glass transition temperature reaches 143°C, it can be used continuously at temperatures up to 260°C, and it can withstand temperatures of 300°C for short periods.

Application of PEEK in CMP Retaining Rings

Chemical Mechanical Polishing (CMP) is a critical step in wafer manufacturing, used to flatten the wafer surface. Due to its wear resistance and dimensional stability, PEEK material is widely used in the production of CMP retaining rings to secure silicon wafers or wafers, ensuring precision and stability in the polishing process.

Manufacture of Wafer Carriers

Wafer carriers are important tools for loading and transporting wafers. The antistatic properties and low outgassing characteristics of PEEK material make it an ideal choice for manufacturing wafer carriers, helping to prevent contamination and damage to wafers during handling.

Manufacture of Photomask Boxes

Photomask boxes are used to store and protect photomasks, which are key components in the lithography process of chip manufacturing. Due to its high cleanliness and chemical corrosion resistance, PEEK material is used to manufacture photomask boxes, ensuring that photomasks remain uncontaminated during storage and use.

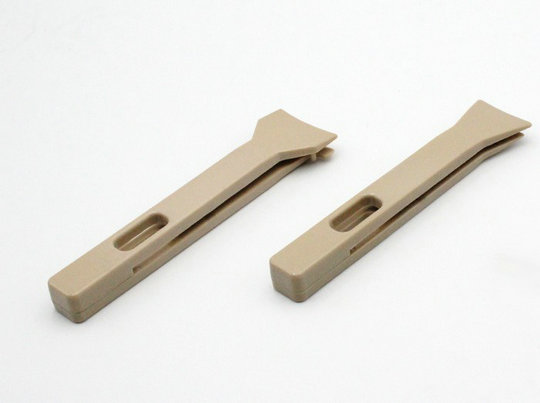

Application in Wafer Tools

Wafer tools, such as wafer clamps and vacuum pens, are used for gripping and handling wafers in manufacturing. The wear resistance and low outgassing properties of PEEK material make it an ideal material for these tools, ensuring the cleanliness and integrity of wafer surfaces.

Antistatic Properties of PEEK Material

In wafer manufacturing, static electricity can damage sensitive semiconductor components. PEEK material, after antistatic modification, can effectively reduce the generation and accumulation of static electricity, protecting wafers from static damage.

Environmental Friendliness of PEEK Material

The recyclability of PEEK material helps to reduce the environmental impact of the wafer manufacturing process, aligning with current demands for sustainable development and environmental protection.

Conclusion

With its superior performance, PEEK material plays an important role in wafer manufacturing. As semiconductor technology continues to advance, the application of PEEK material will become more widespread, providing more reliable and efficient solutions for wafer manufacturing.

Outlook

In the future, as the performance requirements for semiconductor devices increase, the research and application of PEEK material will continue to deepen, bringing more innovation and breakthroughs to wafer manufacturing.

See product of PEEK Wafer Clip