What are the most popular sizes for PEEK sheets?

Common Sizes (LxW)

250 mm x 250 mm

500 mm x 250 mm

500 mm x 500 mm

1000 mm x 500 mm

3000 mm x 500 mm

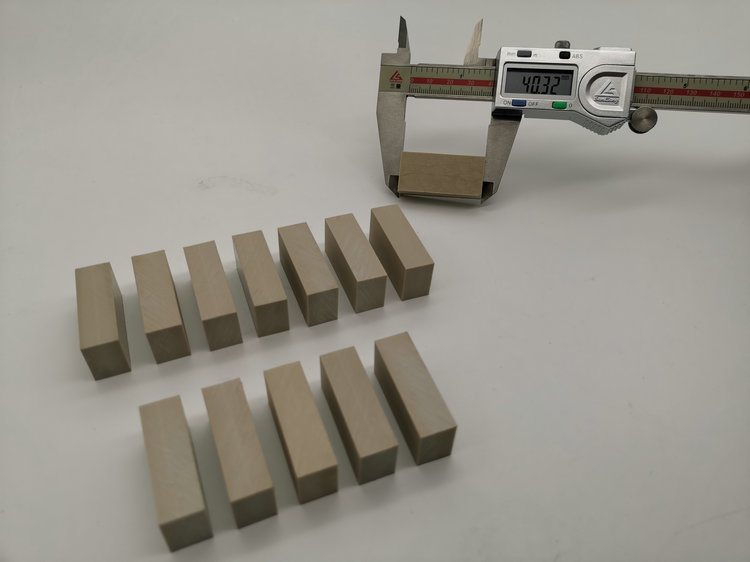

Thickness Options

5 mm

6 mm

8 mm

10 mm

12 mm

16 mm

20 mm

25 mm

30 mm

36 mm

40 mm

50 mm

60 mm

80 mm

How do PEEK sheet sizes affect their pricing?

PEEK sheets come in various sizes, but the most commonly used sizes typically fall within the 10 mm to 50 mm thickness range. These sizes are versatile, cost-effective, and suitable for numerous industrial applications. The most commonly available dimensions for PEEK sheets are:

Thickness: 10 mm to 50 mm

Width: 500 mm to 1000 mm (standard widths)

Length: 500 mm to 1000 mm (standard lengths)

These sizes are ideal for industries that require high-performance materials for components such as seals, bearings, medical implants, and mechanical parts. PEEK sheets within this range strike the best balance between ease of machining and material properties.

Thin vs. Thick PEEK Sheets: How Thickness Affects Pricing

When it comes to PEEK sheets, thickness plays a critical role in determining the cost per unit weight. Both very thin sheets (less than 10 mm) and very thick sheets (more than 50 mm) tend to have a higher weight unit price compared to sheets within the standard 10 mm to 50 mm range. Here's why:

Thin PEEK Sheets (Under 10 mm)

PEEK sheets that are thinner than 10 mm may seem like a cost-effective option at first, but they actually come with a higher unit price per weight. This is because thinner sheets are more difficult and time-consuming to produce. The manufacturing process for thin sheets requires precision and specialized handling to ensure the material remains uniform and free from defects. This complexity, combined with the labor and time needed to produce these thinner sheets, results in higher pricing.

Standard PEEK Sheets (10 mm to 50 mm)

PEEK sheets with thicknesses between 10 mm and 50 mm are the most commonly used and, consequently, offer the best price-to-performance ratio. These sheets are easier to manufacture, process, and machine. They are widely available and are used across industries for a variety of applications, such as fluid systems, gaskets, seals, and bearings. Because they are easier to produce than both thin and thick sheets, they generally have a lower unit cost per weight.

Thick PEEK Sheets (Above 50 mm)

As the thickness of PEEK sheets increases beyond 50 mm, the cost per unit weight also rises. Thicker sheets require specialized machinery and more intensive production techniques to handle and process them. The equipment needed for machining thick PEEK sheets is more advanced and can be more costly to operate. As a result, the manufacturing process for thicker sheets takes more time and resources, which is reflected in the price. This makes thick PEEK sheets suitable for heavy-duty applications, but also comes with a premium price tag due to the increased complexity and material requirements.

Key Pricing Considerations

Production Complexity: The thinner or thicker the PEEK sheet, the more challenging and time-consuming it is to produce. Thin sheets require delicate handling and precision manufacturing, while thick sheets demand specialized machinery and longer processing times.

Material Usage: Thicker sheets consume more raw material, driving up costs. Additionally, the production of thick PEEK sheets often requires more advanced technology, further increasing their cost.

Machining Costs: Both very thin and very thick PEEK sheets tend to incur higher machining costs. Thin sheets are harder to handle, while thick sheets require specific machines for cutting, milling, or shaping, leading to increased labor and tool wear.

End-Use Requirements: Certain industries, such as aerospace or medical applications, may require thicker or thinner PEEK sheets due to specific performance needs. In these cases, customers are often willing to pay the premium price for the specialized properties these sheets offer.

Conclusion

PEEK sheets are available in a wide range of sizes, with 10 mm to 50 mm thickness being the most popular due to their balance of affordability and versatility. However, it’s important to recognize that both thin sheets (under 10 mm) and thick sheets (above 50 mm) come with higher unit prices due to the complexity involved in their production. Whether you need thinner sheets for precision parts or thicker sheets for high-load applications, understanding these pricing dynamics can help you make informed purchasing decisions.

For most applications, standard thickness sheets (10 mm to 50 mm) offer the best value, while those requiring specialized performance may find the investment in thin or thick sheets worthwhile despite the higher cost.

RFQ

Will you charge if buyer need to make customized cutting?

We will charge additional 5% extra cost to cover the material loss.

Could size be custom made?

Yes, it is, we could make it like ultra wide and long.

What's the most thickness you can reach?

100mm.

What's the manufacturing process for the peek sheet?

By extrusion.