Polyetheretherketone (PEEK) is a high-performance thermoplastic with a tensile strength of 14,000–170 MPa (10.2–14.9 ksi) and a glass transition temperature of around 289°F (143°C). PEEK can withstand temperatures as high as 480°F (250°C) for continuous use and is highly resistant to thermal degradation.

Here are some other specifications for PEEK at 73°F:

Tensile modulus of elasticity: 630,000 psi

Tensile elongation at break: 40%

Flexural strength: 25,000 psi

Compressive strength: 16,000 psi

PEEK Tensile Strength vs. Temperature

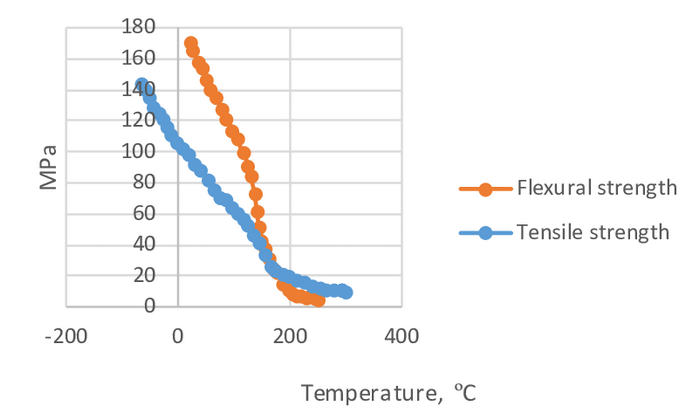

The tensile strength of a material is its ability to withstand a pulling force. For PEEK, this property is highly dependent on the temperature, as illustrated in the provided graph. Here, we observe the behavior of both tensile strength and flexural strength across a range of temperatures.

Low-Temperature Behavior

At sub-zero temperatures, specifically down to -200°C, PEEK exhibits very high tensile strength. The graph shows values exceeding 100 MPa, demonstrating the material's robustness in extremely cold environments.

Room Temperature Performance

At around 0°C to 25°C, PEEK maintains impressive tensile strength, typically around 120-140 MPa. This range is significant for most standard applications, ensuring that PEEK components perform well under typical ambient conditions.

Elevated Temperature Effects

As the temperature increases, a notable decline in tensile strength is observed. From 100°C onwards, the tensile strength begins to decrease more sharply. At approximately 200°C, the tensile strength of PEEK drops below 20 MPa.

Beyond 200°C, the tensile strength continues to diminish, making it less suitable for high-stress applications at these elevated temperatures.

Comparison with Flexural Strength

Interestingly, the flexural strength of PEEK, which is its ability to resist deformation under load, follows a similar trend but retains higher values than tensile strength at elevated temperatures. This makes PEEK a versatile material for applications where bending rather than pulling forces are predominant, even at higher temperatures.

Practical Implications

Cryogenic Applications: The high tensile strength at low temperatures makes PEEK an ideal candidate for cryogenic applications, such as in the space industry or deep-sea exploration.

High-Temperature Uses: While PEEK's tensile strength decreases significantly at temperatures above 200°C, its retention of some mechanical properties means it can still be used in less mechanically demanding roles within high-temperature environments, like certain automotive or electronic components.

General Engineering: For most engineering applications, operating within the 0°C to 100°C range is optimal, ensuring maximum performance and longevity of PEEK components.

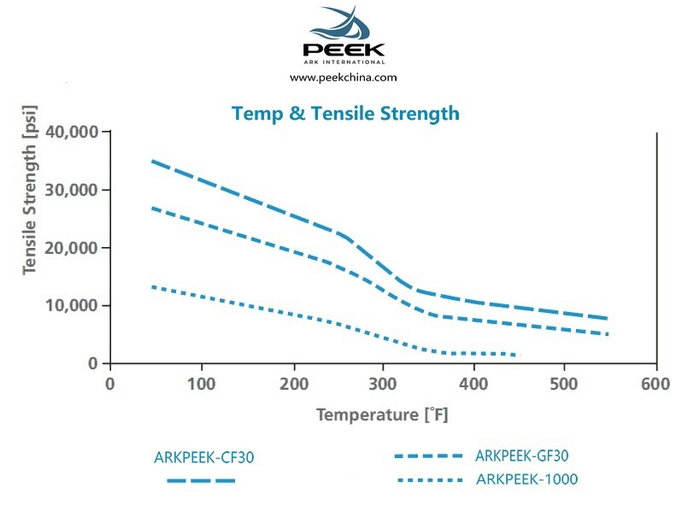

Below is a chart for 3 kinds of ARKPEEK material vs temp.

For more specific data, please visit ARKPEEK Properties.