PEEK's considerable material properties lend it to many medical applications, including many implant applications. PEEK is a frontline option for spinal implants, trauma fixation, cardiovascular implants and in many other fields of medicine. More medical uses for PEEK are on the horizon as the material is being explored and improved upon all the time by medical device manufacturers and various design and engineering firms. Its rapid ascent in medicine has made it the chief challenger to titanium implants, and it has taken the lead in many areas.

PEEK has excellent potential in several areas of medicine, including:

1. Spinal implants – PEEK’s primary medical application is its use as a spinal implant. The material’s efficacy and safety in this role has been proven over years of application and research. Today, PEEK is still featured heavily in spinal implant procedures, and future developments may position it as the most effective option in a wide range of patients.

Patients suffering from degenerative disc disease, degenerative scoliosis, degenerative spondylolisthesis, spinal stenosis or other spine-related disorders can often see considerable relief from the use of a spinal cage or spacer.

It is PEEK’s optimal modulus, which closely mimics cortical bone, and radiolucency that makes it a frontline choice for spinal implant procedures. Its modulus ensures that the implant bears weight like native bone, reducing the likelihood of nearby bone suffering from subsidence and density loss. Its radiolucent properties ensure that surgeons can monitor patient and implant progress following the procedure. These are essential properties to have in an implant, and both can be modified to suit a particular application. If a surgeon prefers less radiolucency from their implant, PEEK can be augmented with a number of additives including Barium Sulfate to provide better contrast.

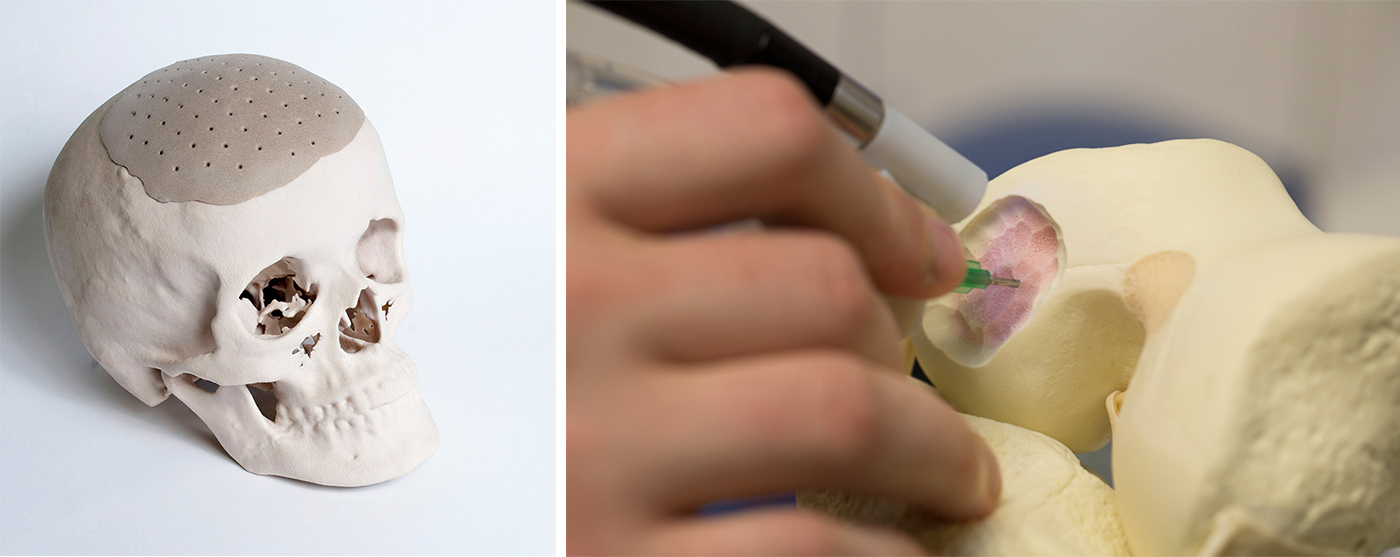

2. Trauma fixation – PEEK’s use in trauma fixation has recently become increasingly important. Surgeons looking for an alternative to metal components have found PEEK to be an ideal alternative when fabricating bone plates, screws, nails, anchors and the like.

PEEK’s increasing role in trauma fixation is due to a few reasons. For one, PEEK bone plates bring superior fatigue strength, extending the fatigue life of implanted components compared to metals like stainless steel. PEEK excels in trauma fixation, again, due to its pure radiolucency. Surgeons can see exactly how their patient’s respond at the injury site following surgery, allowing them to accurately track and predict the healing process. PEEK’s bone-like modulus also serves patients well when used as a trauma fixation device. With its modulus, PEEK offers an optimal mix of flexibility and stiffness, ensuring it doesn’t get in the way of the body’s own healing processes. If needed, PEEK implants can be removed much more easily than metal components, largely due to less bone on-growth with unmodified PEEK.

3. Orthopedic – PEEK is steadily gaining traction in orthopedics, where it can be utilized in a comprehensive array of procedures. This includes knee and hip arthroplasty, and partial or total replacement applications.

Why is PEEK a perfect fit for orthopedics? For most of the same reasons that it works well in spinal and trauma fixation applications. Proper weight bearing is a primary objective for orthopedic surgical teams, which must preserve as much of the natural function of the joint as possible. PEEK makes this easier to accomplish, as its bone-like modulus ensures it will bear weight and move like bone. Unsurprisingly, radiolucency is also important to orthopedic teams, which must track how the body responds to a partial or total joint replacement. PEEK’s radiolucency allows for extremely accurate image reading.

Another PEEK property that is of particular interest in orthopedics is its lightweight nature. PEEK is much lighter than metal, which allows patients to manipulate joints and limbs with less effort than would be necessary with heavier metals. The difference may be subtle, but patients have already reported improved comfort with PEEK components.

4. Cardiovascular – The cardiovascular field continues to explore PEEK for its purposes, but the polymer already plays an essential role in Less Invasive Ventricular Enhancement, or LIVE, procedures. Until recently, the only reliable way to correct damage to the heart following myocardial infarction was with a procedure known as Surgical Ventricular Restoration, or SVR. There are numerous risks associated with SVR, including the risk that comes with having to stop the heart during the procedure. Several incisions are also necessary during SVR, each of which can result in further damage if the surgeon is not extremely precise.

LIVE offers a safer alternative to SVR. During LIVE procedures, a pair of anchors are positioned over the left ventricle, which tends to suffer the most during myocardial infarction. These anchors stabilize the ventricle and ensure it maintains its functionality. The anchors are tied together using a PEEK tether, which keeps the anchors in place, relative to each other. PEEK’s excellent strength as a high-performance polymer is key to LIVE, as a great deal of stress is put on the tether with the heart’s constant beating.

5. Dental – PEEK’s use in dentistry is well-established and is most often incorporated into removable partial dentures. PEEK works well in this role for many reasons. One of the standout reasons is PEEK’s excellent abrasion and compressive resistance, so it can handle chewing and tearing motions. PEEK’s radiolucency is also essential to dental professionals and provides unmatched comfort and aesthetics to patients. Patients report positive outcomes associated with PEEK dental implants as they can easily be made to look like natural teeth, don’t affect taste, feel comfortable, and are not apt to produce an allergic reaction or sores.