PEEK (Polyetheretherketone) is a high-performance thermoplastic polymer that possesses excellent wear properties. These properties make it a popular choice in various industries where durability and resistance to wear are crucial. In this article, we will explore the different factors that contribute to PEEK's exceptional wear properties and highlight its excellence in this regard.

One of the key factors that influence PEEK's wear properties is its inherent chemical structure. PEEK is a semi-crystalline polymer with a unique combination of aromatic and ether linkages. This molecular structure provides PEEK with exceptional chemical resistance, allowing it to withstand exposure to various harsh chemicals and solvents without undergoing significant degradation. As a result, PEEK exhibits excellent wear resistance in chemically aggressive environments.

Another factor that contributes to PEEK's wear properties is its high melting point. PEEK has a melting point of around 343°C (649°F), which is significantly higher than most other thermoplastics. This high melting point enables PEEK to retain its mechanical properties at elevated temperatures, making it suitable for applications where high temperatures are involved. The ability to maintain its strength and wear resistance even at high temperatures sets PEEK apart from many other materials.

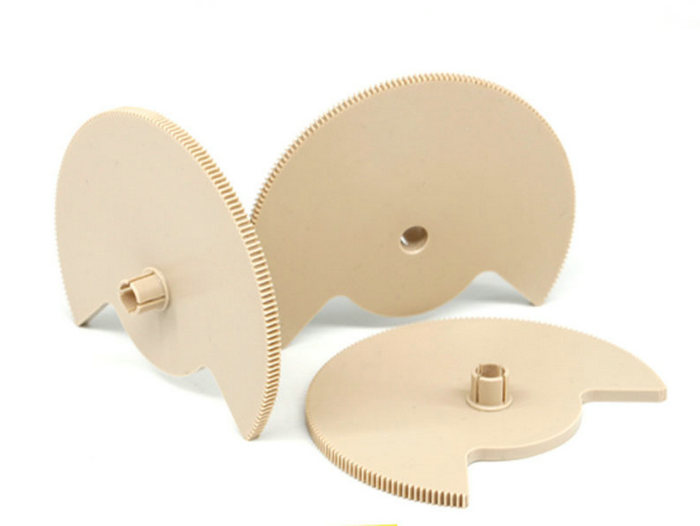

Furthermore, PEEK's low coefficient of friction plays a crucial role in its wear properties. The coefficient of friction determines the resistance to sliding between two surfaces in contact. PEEK has a low coefficient of friction, which means that it exhibits minimal resistance to sliding. This property makes it an excellent choice for applications where low friction and reduced wear are desired, such as bearings and seals.

In addition to its chemical resistance, high melting point, and low coefficient of friction, PEEK also possesses excellent mechanical properties that contribute to its wear resistance. PEEK has a high tensile strength and modulus, which means that it can resist deformation under mechanical stress. This property is particularly important in applications where PEEK components are subjected to high loads or impact forces. Additionally, PEEK has a high fatigue resistance, allowing it to withstand repetitive loading without experiencing significant wear or failure.

PEEK's wear properties are further enhanced by its excellent dimensional stability. PEEK exhibits minimal creep, which refers to the tendency of a material to deform over time under constant stress. This dimensional stability ensures that PEEK components maintain their shape and size even under prolonged use, contributing to their long-term wear resistance.

Moreover, PEEK's wear properties can be optimized through various processing techniques and modifications. For instance, the addition of reinforcing fillers such as carbon fibers or glass fibers can significantly enhance PEEK's wear resistance. These fillers reinforce the polymer matrix, increasing its strength and reducing wear. Additionally, surface treatments such as plasma etching or coating deposition can further improve PEEK's wear properties by enhancing its surface hardness and reducing friction.

PEEK possesses excellent wear properties due to its unique combination of chemical structure, high melting point, low coefficient of friction, mechanical strength, dimensional stability, and processability. These properties make PEEK a versatile material that can withstand demanding environments and applications where wear resistance is crucial. Whether it is used in aerospace, automotive, medical, or other industries, PEEK continues to demonstrate its excellence in providing exceptional wear performance.