Overview

PEEK (Polyether ether ketone) is a high-performance thermoplastic known for its excellent mechanical strength, chemical resistance, and high-temperature tolerance. It is widely used in aerospace, medical, automotive, and other fields. Machining PEEK requires special processes and tools to achieve high-quality parts.

Methods

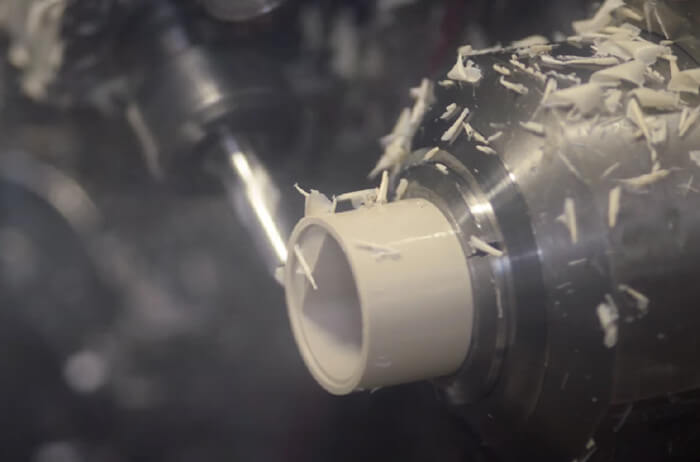

PEEK can be machined using various methods, including turning, milling, drilling, and grinding. Among these, turning and milling are commonly used. During machining, it is necessary to use specialized cutting tools and coolants to prevent tool wear and material deformation.

Precautions

PEEK tends to produce burrs and chips during machining, so special measures are needed to remove these burrs and chips. Additionally, PEEK has a relatively high coefficient of thermal expansion, so the impact of thermal expansion must be considered during the machining process.

Is PEEK hard to machine?

PEEK plastic machining is difficult because of the preparations the plastic must undergo before it can be machined. With PEEK CNC machining, the material PEEK arrives in sheet, rod and cutting form. Due to PEEK plastic's properties, it needs to be annealed before it can be fabricated into a specific shape and size.

What is PEEK machining?

The material PEEK is characterised by high dimensional stability combined with well-balanced mechanical properties. This combination of properties is responsible for the very good machinability of PEEK material. In PEEK plastic machining, high tool infeeds and high feed rates can be used.

What is PEEK material for CNC?

What is PEEK? Using PEEK materials (chemically known as polyetheretherketone) is ideal for a wide spectrum of CNC machining applications where thermal, chemical, and combustion properties are critical to performance.

What material is used to cut PEEK?

Silicon carbide cutting tools work well for natural PEEK, while diamond tools work well for PEEK reinforced with carbon-fiber. For medical-grade PEEK applications, the best way to avoid jeopardizing the biocompatibility of the material is to machine dry.

What is the tolerance of PEEK in machining?

If we go into greater detail, the material is very stable and can achieve +/- . 0005 tolerances and overall surface finish of 32, typically porting to 16. Due to PEEK's high tensile strength, thread inserts are generally not necessary except for high assembly and disassembly situations.

Is unfilled PEEK machinability?

Machinability. The machinability of un-filled PEEK is very good. The glass or carbon fibre reinforced grades will require tipped tooling.

Can PEEK be annealed?

A common annealing routine for PEEK is a 2-hr exposure to 200 ℃ (392 F). This temperature is well above the Tg of the polymer and will effectively provide that last little bit of crystallinity that we could not obtain from the molding process.