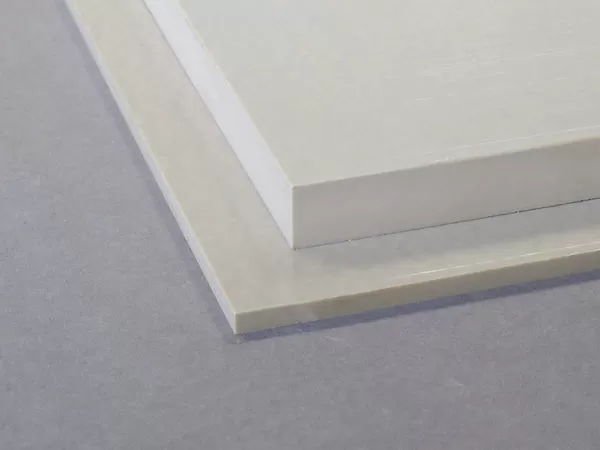

Medical-grade Biocompatible PEEK

PEEK Biocompatible is a cutting-edge solution designed to revolutionize the field of biocompatible materials. Engineered to meet the highest standards of biocompatibility, our PEEK polymers are the ideal choice for applications in the medical and life sciences industries. These materials provide exceptional strength, durability, and precision, ensuring the safety and well-being of patients and the success of research endeavors. With PEEK Biocompatible, you can confidently pursue medical device innovation, implant solutions, and life science projects, all aimed at improving and safeguarding lives.

Discover the future of biocompatibility with our PEEK Biocompatible materials. Engineered to excel in medical and life science applications, our PEEK polymers offer a unique blend of biocompatibility, mechanical strength, and versatility. Whether you're developing medical implants, laboratory equipment, or research tools, our PEEK Biocompatible solutions empower you to create with confidence. Prioritize safety, precision, and innovation in your projects with the exceptional properties of our PEEK Biocompatible materials.

| Properties Information | ||||||

| Property | Reference Standard | Test Method | Unit | Specification | Result | |

| Physical Properties | Glass Transition | ASTM F2026 | ASTM D3418 | °C | 125-165 | 147 |

| Temperature, Tg | ||||||

| Melt Temperature, Tm | ASTM F2026 | ASTM D3418 | °C | 320-360 | 338 | |

| Recrystallization | ASTM F2026 | ASTM D3418 | °C | 260-320 | 289 | |

| Temperature, Tc | ||||||

| Viscosity | ASTM F2026 | ISO 11443 | Pa·s | 400-480 | 437 | |

| Infrared Spectrum | ASTM F2026 | ASTM F1579 | / | See Appendix X1 | See Appendix X2 | |

| Density | ASTM F2026 | ASTM D1505 | kg/m3 | 1280-1320 | 1294 | |

| Chemical Properties | Total Heavy Metals (Ag, As, Bi, Cd, Cu, Hg, Mo, Pb, Sb, and Sn), max | ASTM F2026 | US Pharmacopeia, | ppm | <100 | <10 |

| Test 233 | ||||||

| Mechanical Properties | Tensile Strength at Yield (zero slope), min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | MPa | 90 | 105 |

| Tensile Strength at Break, min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | MPa | 70 | 80 | |

| Elongation at Break, min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | % | 5 | 18 | |

| Flexural Strength, min | ASTM F2026 | ASTM D790 | MPa | 110 | 163 | |

| Flexural Modulus, min | ASTM F2026 | ASTM D790 | GPa | 3 | 4 | |

| Impact Strength, | ASTM F2026 | ISO 180 | kJ/m2 | 4 | 9 | |

| Notched Izod, min | ||||||

| Biological Properties | Genotoxicity | ISO 10993-3 | ISO 10993-3 | / | Negative | Negative |

| Animal Intracutaneous (Intradermal) Reactivity | ISO 10993-10 | ISO 10993-10 | / | ≤1 | 0 | |

| Skin Sensitization | ISO 10993-10 | ISO 10993-10 | / | ≤1 | 0 | |

| Acute Systemic Toxicity | ISO 10993-11 | ISO 10993-11 | / | No Acute Systemic Toxicity | No Acute Systemic Toxicity | |

| Subchronic Systemic Toxicity | ISO 10993-11 | ISO 10993-11 | / | No Subchronic Systemic Toxicity | No Subchronic Systemic Toxicity | |

| local Effects After Implantation | ISO 10993-6 | ISO10993-6 | / | No obvious difference between the test sample and the control sample | No obvious difference between the test sample and the control sample | |

| In Vitro Cytotoxicity | ISO 10993-5 | ISO10993-5 | / | ≤1 | 1 | |

| Evaluation of Haemolytic Properties | ISO 10993-4 | ISO10993-4 | % | <5 | 1 | |

| Material Mediated Pyrogens | ISO 10993-11 | ISO 10993-11 | / | No Pyrogenic Responses | No Pyrogenic Responses | |

| Extractables of The Material | ISO 10993-18 | ISO 10993-18 | μg/g | The contents of Phenyl Sulfone≤300 | The contents of Phenyl Sulfone<0.09 | |