Manufacturing Process

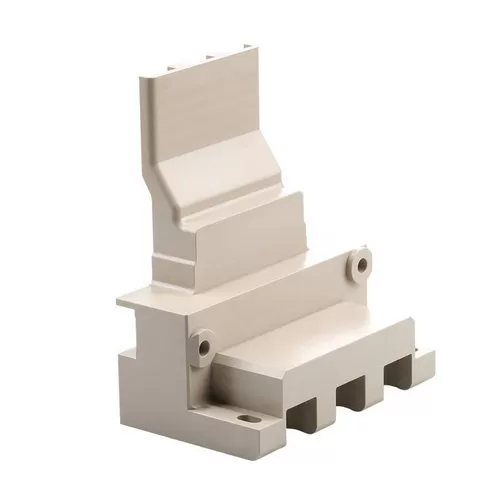

CNC Machining & Injection Molding

Glass Filled PEEK Thermal Properties

High Operating Temperature: Glass-filled PEEK can withstand temperatures up to 250°C (482°F).

Low Thermal Expansion: It has minimal dimensional changes with temperature.

Low Thermal Conductivity: It's a poor conductor of heat, useful for insulation.

Flame-Resistant: PEEK is inherently flame-resistant with low smoke emissions.

30 Glass Filled PEEK Material Properties

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK-GF30 glass filled PEEK parts are engineered from a high-performance polyetheretherketone (PEEK) composite reinforced with 30% glass fiber, significantly enhancing mechanical strength, rigidity, and dimensional stability. This advanced material maintains excellent performance under continuous service temperatures up to 250°C (482°F) and short-term exposure up to 300°C (572°F), making it ideal for demanding applications where reliability and durability are critical.

The glass fiber reinforcement reduces creep deformation and thermal expansion, ensuring parts retain precise dimensions and structural integrity over long periods under static loads and thermal cycling. ARKPEEK-GF30 also exhibits outstanding chemical inertness, resisting hydrolysis, UV degradation, and aggressive media including acids, alkalis, and hydrocarbons across a wide pH range (0–14).

These properties make ARKPEEK-GF30 parts suitable for mission-critical components in aerospace fuel systems, automotive EV battery cooling assemblies, medical device housings, semiconductor manufacturing equipment, and industrial machinery exposed to harsh chemicals and elevated temperatures.

Key features include:

Enhanced Mechanical Strength & Rigidity: Glass fiber reinforcement boosts flexural modulus (≥10 GPa) and wear resistance.

Thermal Stability: Maintains mechanical and dimensional stability at elevated temperatures, reducing risk of deformation.

Chemical Resistance: Inert to a broad spectrum of aggressive chemicals, solvents, and environmental factors.

Dimensional Precision: Low coefficient of thermal expansion (2.5 x 10⁻⁵/K) ensures tight tolerances in precision assemblies.

Electrical Insulation: High volume resistivity (>10¹⁶ Ω·cm) suitable for electrical and electronic applications.

Compliance & Quality: Meets ISO 10993 biocompatibility, UL 94 V-0 flammability, and ASTM D638 tensile strength standards.

Manufactured using advanced extrusion, injection molding, or CNC machining, ARKPEEK-GF30 parts offer excellent surface finishes and tight dimensional control, supporting complex geometries and critical tolerances.

Choosing ARKPEEK-GF30 glass filled PEEK parts delivers a reliable, high-performance polymer solution that enhances durability, reduces maintenance, and improves operational efficiency in the most challenging industrial, medical, and aerospace environments.