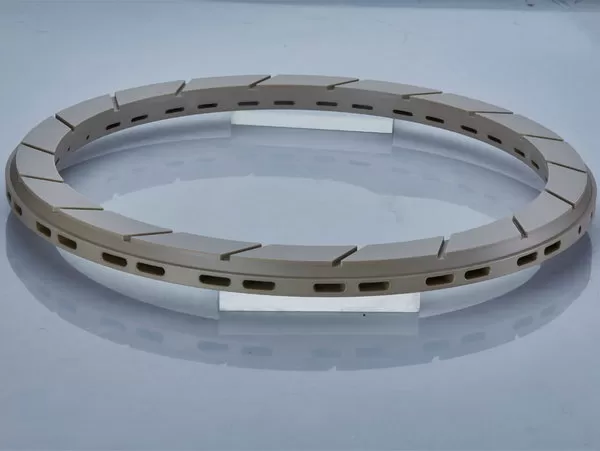

The PEEK CMP Ring is engineered for optimal performance in chemical mechanical polishing (CMP) processes, offering superior durability and chemical resistance. Manufactured from high-performance Polyether Ether Ketone (PEEK), these rings excel in high-temperature environments and exhibit excellent wear resistance, making them ideal for demanding applications in the semiconductor industry. With low friction and exceptional mechanical properties, PEEK CMP Rings ensure precision, stability, and efficiency, contributing to enhanced productivity and extended component life in your CMP systems.

The PEEK CMP Ring is a high-performance component specifically designed for demanding chemical mechanical polishing (CMP) applications. Made from Polyether Ether Ketone (PEEK), a premium thermoplastic known for its exceptional mechanical and chemical properties, these rings offer superior durability, wear resistance, and chemical stability. PEEK CMP Rings are engineered to provide precision, efficiency, and long-lasting reliability, making them indispensable in the semiconductor industry and other advanced manufacturing environments.

One of the key advantages of PEEK CMP Rings is their ability to perform consistently under extreme conditions. They exhibit excellent resistance to high temperatures, ensuring that the rings maintain their structural integrity during intense CMP processes. Additionally, PEEK’s natural resistance to corrosive chemicals means that these rings can withstand the harsh chemical environments typically encountered in CMP operations. This unique combination of properties allows for greater efficiency in polishing processes, reducing the frequency of component replacements and minimizing costly downtime.

PEEK CMP Rings also boast low friction, which enhances the precision and quality of the polishing process. The smooth, controlled movement they provide ensures even distribution of pressure during polishing, resulting in more consistent, high-quality surface finishes. This not only improves the final product quality but also increases the overall efficiency of the CMP process by reducing wear and tear on both the ring and the polishing equipment.

In addition to these functional benefits, PEEK CMP Rings offer long-term cost savings. Their superior wear resistance means that they outlast many traditional materials used in CMP processes, such as metals or ceramics, which can degrade quickly under similar conditions. This extended lifespan translates into fewer replacements, less downtime, and lower maintenance costs, making PEEK CMP Rings a cost-effective choice for manufacturers looking to optimize their operations.

Ideal for use in semiconductor fabrication, data storage devices, and other precision machining applications, PEEK CMP Rings are a trusted solution for companies seeking high performance, reliability, and efficiency in their CMP processes. Whether you’re looking to improve the durability of your CMP components or seeking to enhance the precision of your polishing operations, PEEK CMP Rings offer the advanced features necessary to meet your needs.

What is a peek ring?

PEEK rings are designed to prevent extrusion in elastomer O-ring sealing systems.

What is a CMP retainer ring?

The retaining ring is an integral part of the CMP process and functions to hold the wafer under the carrier during polishing, to secure it from slipping out of the carrier head, and to achieve uniform material removal.