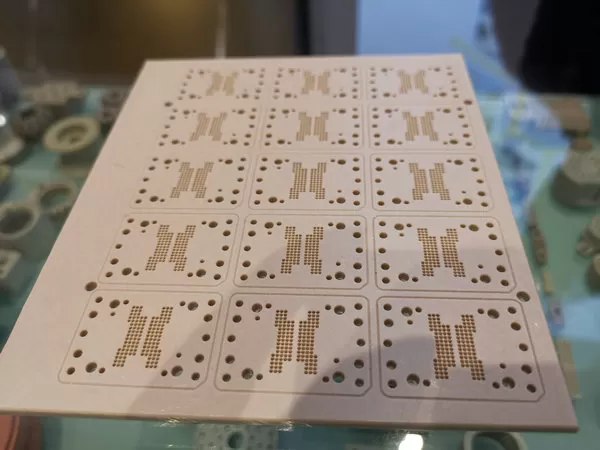

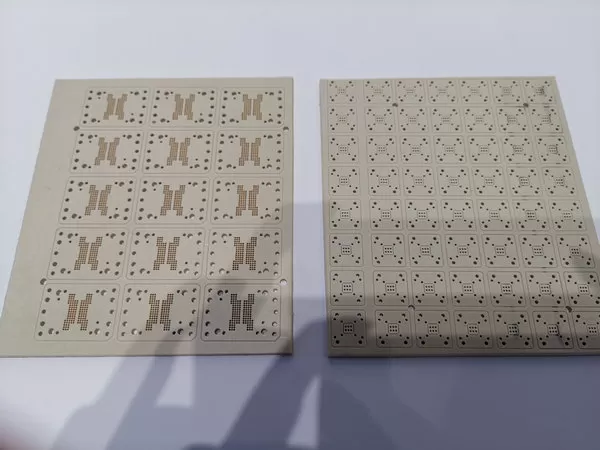

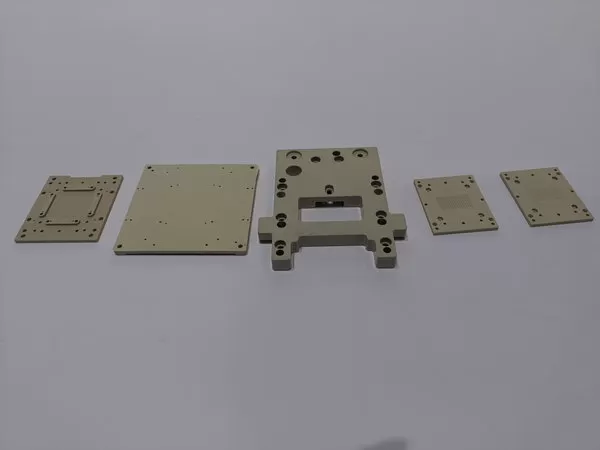

The PEEK Electronic Circuit Board is a high-performance PCB crafted from polyetheretherketone (PEEK), designed to thrive in extreme temperatures (up to 480°F/250°C), corrosive environments, and high-stress applications. Perfect for aerospace systems, medical devices, and industrial automation, it delivers superior electrical insulation, lightweight durability, and resistance to chemicals and wear.

_______________________________________________________________________________________________________________________________________________________________________

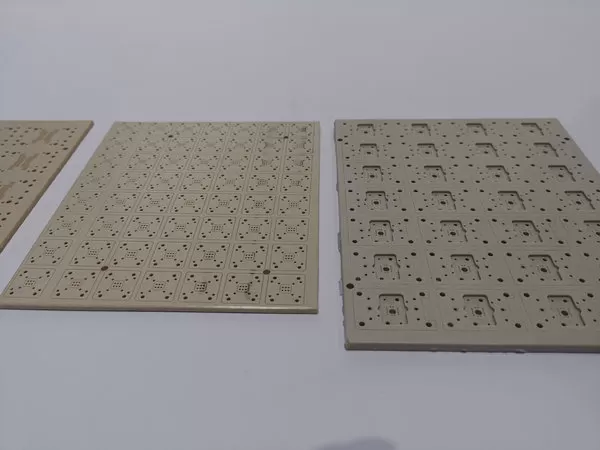

PEEK electronic circuit boards, made from high-performance polyetheretherketone (PEEK) materials such as ARKPEEK, are engineered to meet the rigorous demands of modern electronic and semiconductor industries. These PCBs offer exceptional thermal stability, maintaining mechanical and electrical integrity at continuous temperatures up to 260°C (500°F), far exceeding many traditional PCB substrates.

The superior chemical resistance of PEEK ensures that circuit boards remain unaffected by aggressive solvents, acids, and cleaning agents commonly used in semiconductor fabrication and harsh industrial environments. This chemical inertness preserves the purity and reliability of sensitive electronic components, making PEEK PCBs ideal for cleanroom and medical applications.

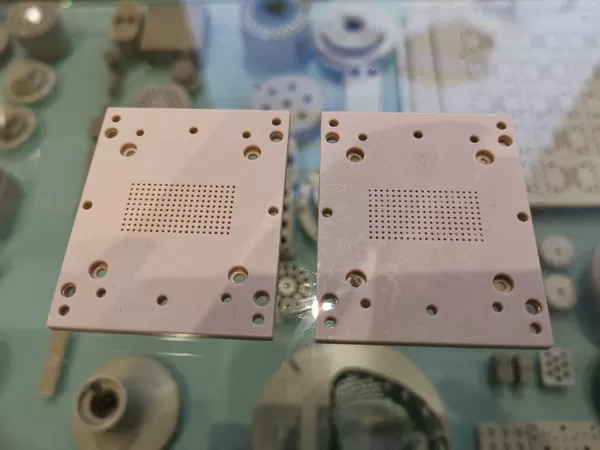

PEEK’s excellent dielectric properties—including high dielectric strength, low dielectric loss, and a low dissipation factor—enable superior electrical insulation and signal integrity, critical for high-frequency and high-voltage electronic circuits. Additionally, PEEK’s low moisture absorption and dimensional stability prevent warping and degradation, ensuring long-term reliability and performance.

These circuit boards also benefit from PEEK’s mechanical strength and wear resistance, supporting robust connector mounting and reducing failure risks in vibration-prone aerospace and automotive environments. The lightweight nature of PEEK contributes to overall device weight reduction, enhancing portability and energy efficiency.

Applications

Aerospace and defense electronic systems requiring high thermal and chemical resilience

Semiconductor wafer handling and processing equipment

Medical diagnostic and implantable electronic devices

High-frequency communication and RF circuit boards

Industrial control systems exposed to corrosive or high-temperature conditions

Compared to conventional materials like FR4, polyimide, or PTFE, PEEK PCBs deliver an unmatched balance of thermal endurance, chemical resistance, electrical insulation, and mechanical durability. This makes them the preferred choice for next-generation electronics where performance and reliability are paramount.

By choosing PEEK electronic circuit boards, manufacturers ensure superior device longevity, enhanced operational stability, and compliance with stringent industry standards in the most demanding environments.