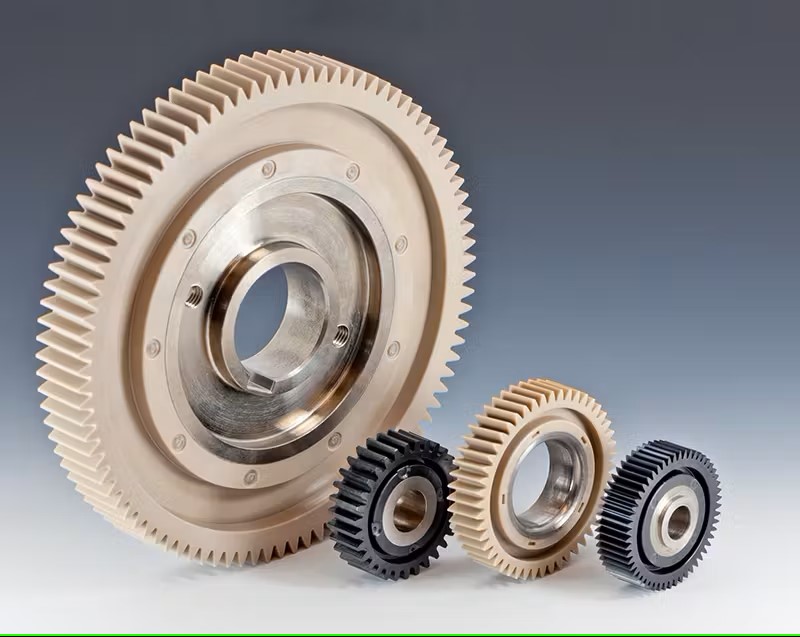

ARKPEEK PEEK gears are engineered from high-quality PEEK material, providing excellent wear resistance, low noise, high-temperature stability, and chemical inertness. Perfect for demanding aerospace, medical, automotive, and industrial applications requiring durable, lightweight, and reliable gear solutions.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK PEEK gears are advanced, high-performance gears manufactured from premium polyetheretherketone (PEEK), a top-tier engineering thermoplastic renowned for its outstanding combination of mechanical strength, chemical resistance, and high-temperature stability. These gears are ideal for use in environments where durability, precision, and reliability are critical, such as aerospace, automotive, medical devices, and industrial automation.

Key features of ARKPEEK PEEK gears include:

Exceptional Wear Resistance & Low Friction: PEEK’s self-lubricating properties reduce maintenance needs and operational noise, ensuring smooth and quiet gear operation.

High-Temperature Performance: Capable of functioning continuously at temperatures up to 260°C (500°F), maintaining dimensional stability and mechanical integrity.

Corrosion & Chemical Resistance: Resistant to acids, bases, solvents, and hydrolysis, making them suitable for aggressive chemical environments.

Lightweight & High Strength: Significantly lighter than metal gears (density around 1.3-1.4 g/cm³), reducing overall system weight and improving energy efficiency—especially beneficial in aerospace and automotive sectors.

Precision & Machinability: Easy to produce complex gear designs with high accuracy through injection molding or machining, supporting custom and high-precision applications.

Noise Reduction: PEEK gears operate more quietly compared to metal gears, ideal for noise-sensitive environments like medical equipment and office machinery.

Application Areas:

Aerospace: Fuel systems, flight control systems, and lightweight gear components that withstand high temperatures and corrosive fuels.

Automotive: Engine, transmission, electric power steering, and braking systems that benefit from lightweight, durable, and low-noise gears.

Medical Devices: Surgical robots, sterilizable medical equipment, and implantable devices requiring biocompatibility and sterilization resistance.

Industrial Automation: Robotics, CNC machines, and production lines where high precision, wear resistance, and long service life are essential.

Manufactured using advanced injection molding or precision machining, ARKPEEK PEEK gears combine innovative material properties with manufacturing flexibility, providing reliable, cost-effective, and high-performance gear solutions for the most demanding applications.