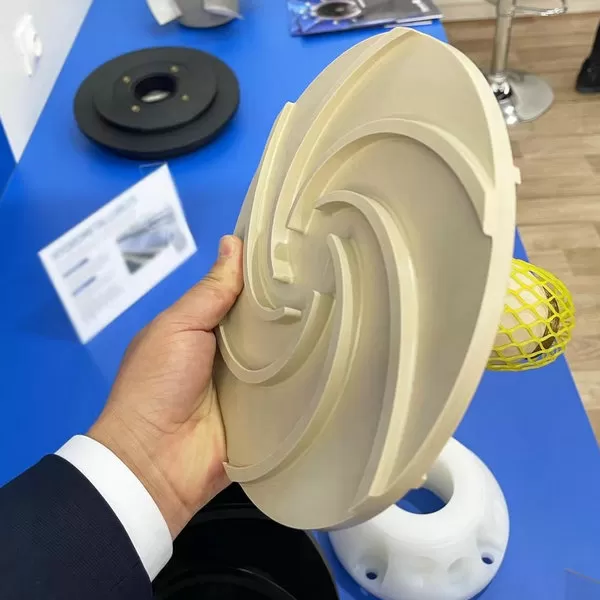

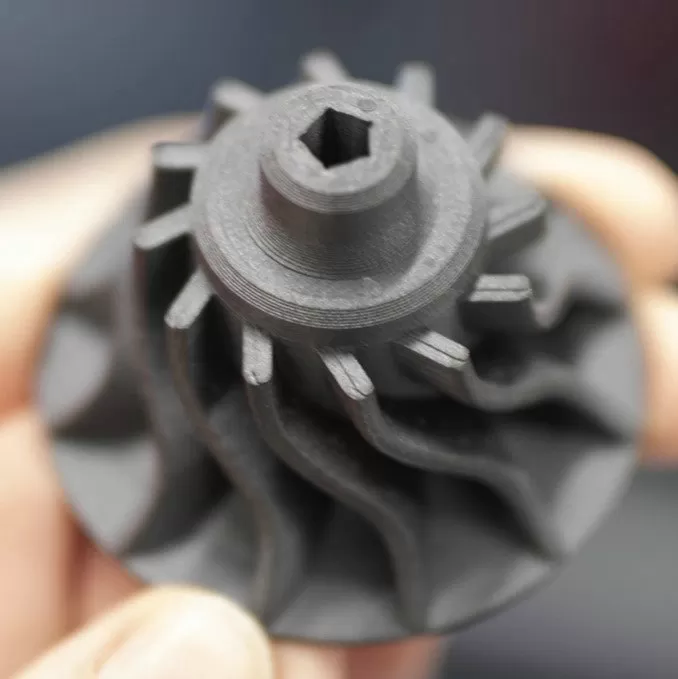

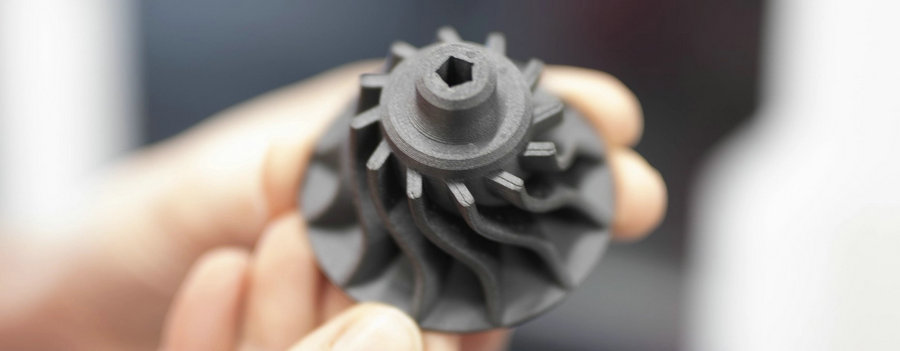

PEEK impellers are high-performance components crafted from Polyether Ether Ketone (PEEK) material, known for their exceptional durability, chemical resistance, and lightweight properties. These impellers are engineered to withstand extreme conditions, including high temperatures and corrosive environments, making them ideal for applications in industries such as chemical processing, medical devices, and aerospace. Their unique blend of strength, stability, and low density ensures efficient fluid dynamics and long-term reliability in demanding scenarios.

PEEK impellers are sophisticated components designed from Polyether Ether Ketone, a high-performance polymer renowned for its remarkable mechanical and thermal properties. These impellers are integral to a wide range of industrial applications due to their exceptional resistance to chemicals, wear, and high temperatures. PEEK impellers are highly valued in sectors such as chemical processing, medical equipment, and aerospace, where they offer significant advantages over traditional materials like metals and other polymers.

The intrinsic properties of PEEK, including its low density and high strength-to-weight ratio, make these impellers lightweight yet robust, contributing to efficient fluid handling and reduced energy consumption. Moreover, PEEK's biocompatibility allows for safe use in medical devices, while its thermal stability ensures consistent performance even under extreme conditions. Customizable to meet specific application requirements, PEEK impellers provide a versatile and durable solution for enhancing system efficiency and reliability. Whether dealing with corrosive fluids, high-pressure systems, or stringent regulatory standards, PEEK impellers offer unparalleled performance and longevity.