Custom PEEK machined parts are crafted to meet the unique demands of industries requiring high-precision and high-performance materials. PEEK's excellent properties, including its resistance to chemicals, high temperatures, and mechanical stress, make it a versatile material for complex applications. Whether used in semiconductor manufacturing, oil and gas exploration, or medical implants, PEEK components deliver reliable performance under extreme conditions.

PEEK (Polyether Ether Ketone) machined components are premium solutions designed for applications that demand superior performance and durability. As a high-performance engineering thermoplastic, PEEK stands out for its unique combination of properties, making it an ideal choice for critical applications across various industries, including aerospace, medical, oil and gas, and semiconductor manufacturing.

Key Features and Benefits:

PEEK machined components offer outstanding chemical resistance, making them suitable for use in environments exposed to aggressive chemicals and solvents. The material's exceptional thermal stability allows it to maintain its mechanical properties at elevated temperatures, with a continuous service temperature of up to 250°C (482°F) and short-term exposure capability up to 300°C (572°F). This makes PEEK ideal for high-temperature applications, such as in automotive engines and industrial equipment.

In addition to its thermal properties, PEEK exhibits excellent mechanical strength and stiffness, providing high load-bearing capacity and wear resistance. Its inherent toughness and fatigue resistance contribute to the longevity and reliability of PEEK components, even under continuous stress and dynamic conditions. Furthermore, PEEK's low coefficient of friction and high abrasion resistance make it an excellent choice for applications requiring low wear and long service life.

One of PEEK's standout features is its biocompatibility, which makes it a preferred material for medical devices. The material is compatible with sterilization methods such as autoclaving, gamma radiation, and ethylene oxide, ensuring it meets stringent medical standards. PEEK's low density also contributes to the development of lightweight components, offering advantages in applications where weight reduction is critical.

Customization and Precision Engineering

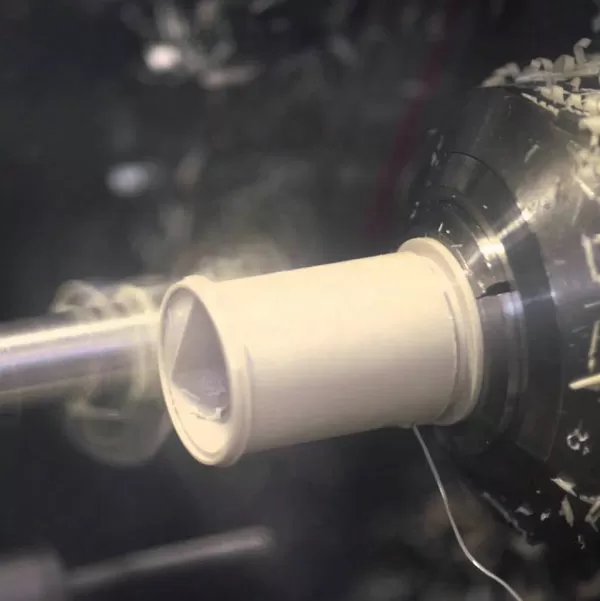

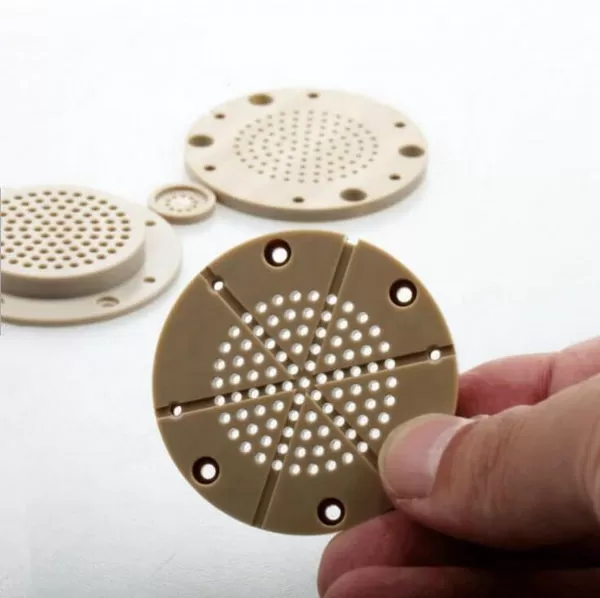

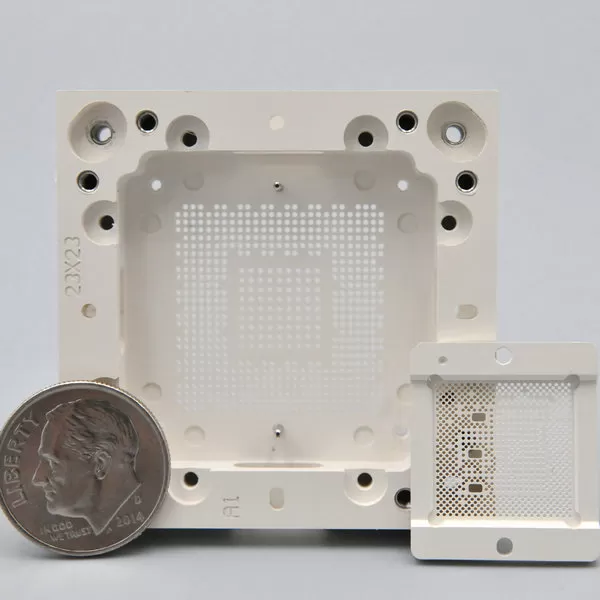

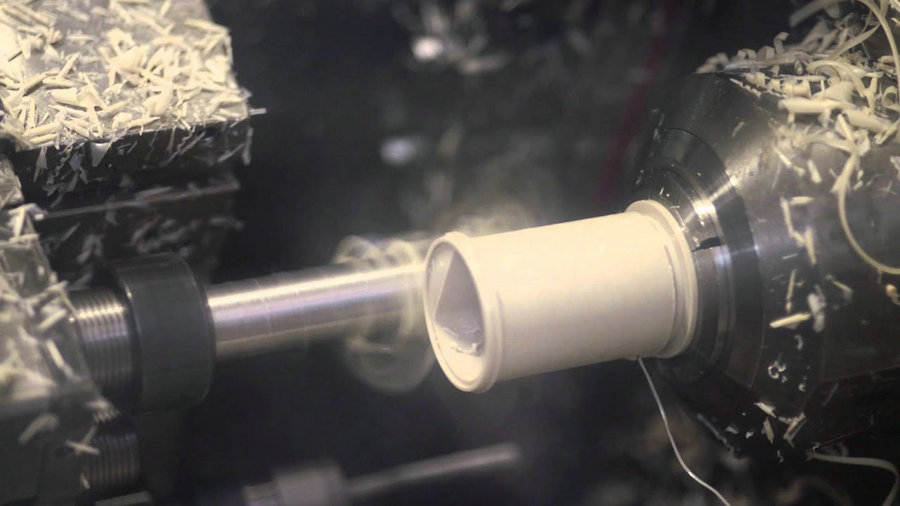

PEEK machined components can be custom-designed to meet specific application requirements. Advanced CNC machining techniques enable the production of intricate and precise parts with tight tolerances. Whether you need components with complex geometries or specialized features, PEEK's versatility allows for high customization, ensuring optimal fit and function in the final product.

Applications

The versatility of PEEK makes it suitable for a wide range of applications. In aerospace, PEEK components are used in structural parts, insulation, and fasteners due to their high strength-to-weight ratio and flame retardancy. In the medical field, PEEK is utilized for implants, surgical instruments, and prosthetics because of its biocompatibility and radiolucency. The oil and gas industry benefits from PEEK's chemical resistance and durability in seals, valves, and compressor parts. Meanwhile, in the semiconductor industry, PEEK is employed in wafer handling and processing equipment, offering excellent purity and dimensional stability.

In summary, PEEK machined components provide a unique blend of properties that meet the stringent demands of high-performance applications. With exceptional chemical resistance, thermal stability, mechanical strength, and biocompatibility, PEEK continues to be a material of choice for industries requiring reliable and durable solutions. Whether for custom or standard applications, PEEK components deliver unparalleled performance, making them a valuable asset in modern engineering and technology.

What is the tolerance of PEEK in machining?

If we go into greater detail, the material is very stable and can achieve +/- . 0005" or +/-0.01mm tolerances.

Can you anneal PEEK?

Yes, a common annealing routine for PEEK is a 2-hr exposure to 200 ℃ (392 F).