Manufacturing Process

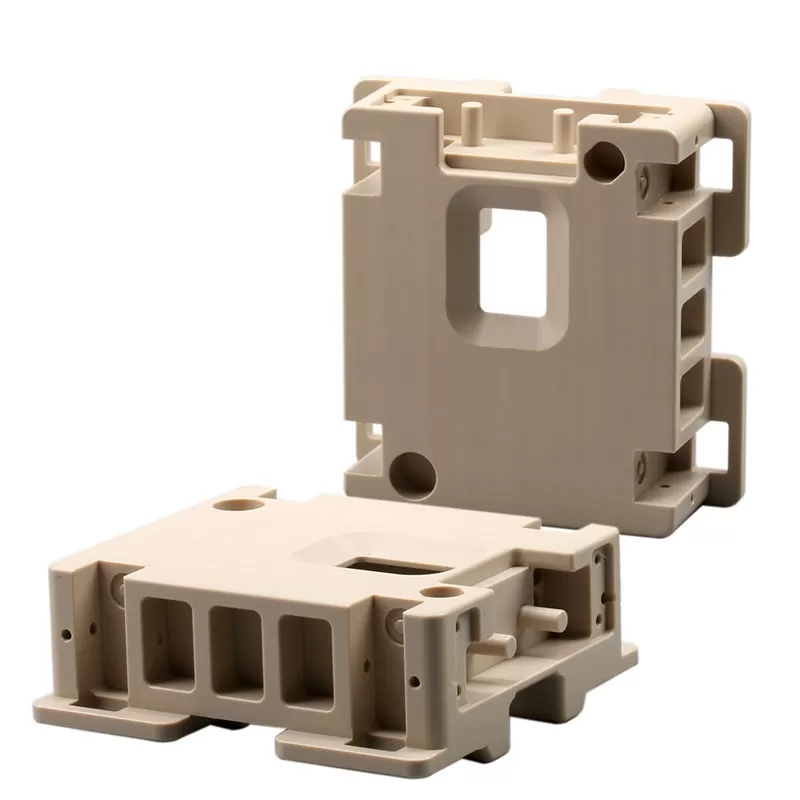

CNC Machining & Injection Molding

PEEK Material Performance

Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance.

_______________________________________________________________________________________________________________________________________________________________________

PEEK parts, made from polyetheretherketone, are high-performance engineering components designed to meet the rigorous demands of harsh industrial environments. Renowned for their outstanding wear resistance, chemical inertness, and ability to withstand continuous temperatures up to 260°C (500°F), PEEK parts serve as reliable alternatives to metals in aerospace, automotive, medical, chemical processing, and electronics industries.

These parts excel in applications requiring resistance to aggressive chemicals, hydrolysis, and mechanical fatigue. Their lightweight nature contributes to fuel efficiency and noise reduction in automotive and aerospace systems, while their excellent electrical insulation properties make them ideal for sensitive electronic and semiconductor equipment.

Manufacturing methods such as injection molding, extrusion, compression molding, and CNC machining allow production of complex geometries with tight tolerances and excellent surface finishes. This versatility supports both high-volume production runs and custom prototype fabrication.

Typical Applications

Aerospace components like seals, bearings, and piston parts that endure extreme temperatures and mechanical stress.

Automotive parts such as gears, bushings, and connectors that require chemical resistance and durability under thermal cycling.

Medical devices benefiting from biocompatibility and sterilization resistance, including surgical instruments and implants.

Chemical processing equipment components exposed to harsh solvents and hydrocarbons.

Electrical and electronic parts requiring high purity, low outgassing, and electrical insulation.

PEEK parts made from advanced grades like ARKPEEK combine superior mechanical properties with excellent chemical and thermal stability, enabling longer service life and reduced maintenance costs. Their ability to replace metals without compromising strength or performance makes them a preferred choice for innovative engineering solutions across multiple industries.