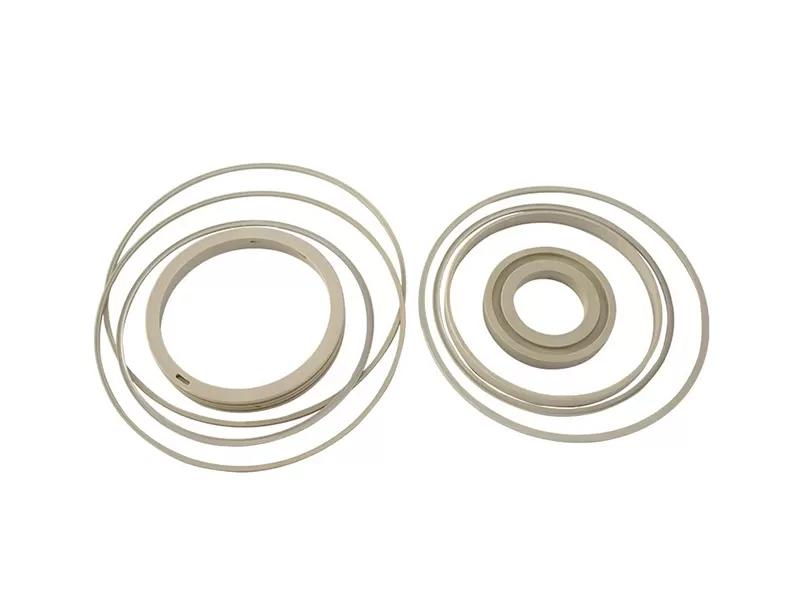

PEEK Sealing Material

Our PEEK Seals, crafted from advanced ARKPEEK grades including 1000, CF30, GF30, and MOD, offer exceptional performance under high pressure, high temperature, and chemically aggressive environments—perfect for precision sealing in demanding industries.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK seals are engineered to outperform traditional sealing solutions in the most demanding environments. Made from advanced PEEK polymer composites—including PEEK 1000 (virgin grade), CF30 (30% carbon fiber-reinforced), GF30 (30% glass fiber-reinforced), and MOD (lubricated for reduced friction)—these seals combine exceptional mechanical strength, thermal stability, and chemical resistance to ensure leak-free operation and extended service life.

Material Advantages

PEEK 1000: Ideal for high-purity applications (medical, semiconductor) with excellent resistance to steam, acids, and bases.

CF30: Carbon fiber reinforcement enhances stiffness and load capacity for high-pressure industrial systems.

GF30: Glass fiber reinforcement improves dimensional stability in fluctuating temperatures.

MOD: Self-lubricating properties minimize wear in dynamic sealing applications like pumps and rotating equipment.

Critical Applications

Industrial: Seals for valves, pumps, compressors, and hydraulic systems exposed to aggressive chemicals (e.g., oil & gas, chemical processing).

Medical: Biocompatible, sterilizable seals for surgical instruments, drug delivery systems, and MRI equipment.

Automotive: High-temp engine seals, fuel systems, and EV battery components resistant to oils and coolants.

Aerospace: Lightweight, flame-retardant seals for fuel lines, actuators, and cabin pressure systems.

Why Choose ARKPEEK Seals?

Extreme Durability: Withstand temperatures from -196°C to +260°C (-320°F to +500°F) and pressures up to 30,000 psi.

Chemical Resistance: Impervious to acids, bases, solvents, and hydrocarbons, ensuring longevity in corrosive environments.

Low Friction & Wear: MOD-grade PEEK reduces maintenance needs in high-cycle applications.

Customizable: Available in standard sizes or custom-machined to precise dimensions (±0.01mm tolerance).

Technical Specifications

Certifications: FDA-compliant, ISO 10993 (biocompatibility), and REACH/RoHS-certified.

Surface Finishes: Optional coatings (e.g., PTFE, Xylan) for enhanced lubricity or electrical insulation.

Compatibility: Designed to replace metal, rubber, or PTFE seals with superior performance.

Cost-Saving Benefits

Reduced Downtime: Precision-engineered for drop-in replacement, minimizing system shutdowns.

Longer Lifespan: Outlast metal or plastic seals by 3–5x, lowering total ownership costs.

Energy Efficiency: Low friction reduces power consumption in pumps and rotating machinery.

Upgrade to ARKPEEK Seals Today

Whether you’re battling chemical corrosion, extreme temperatures, or frequent seal failures, ARKPEEK seals offer a robust, long-term solution. Trusted by engineers in aerospace, healthcare, and heavy industry, our seals are backed by ISO 9001-certified manufacturing and rapid global delivery. Contact us for custom quotes, CAD support, or urgent replacements to keep your systems running flawlessly.