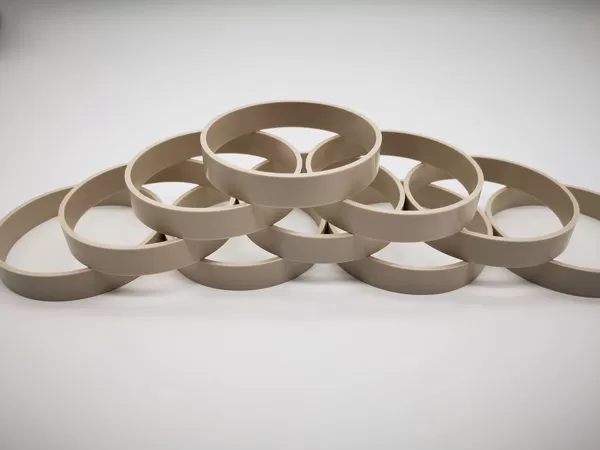

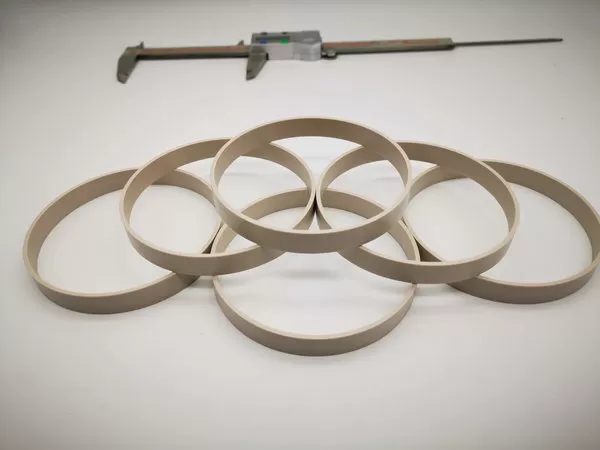

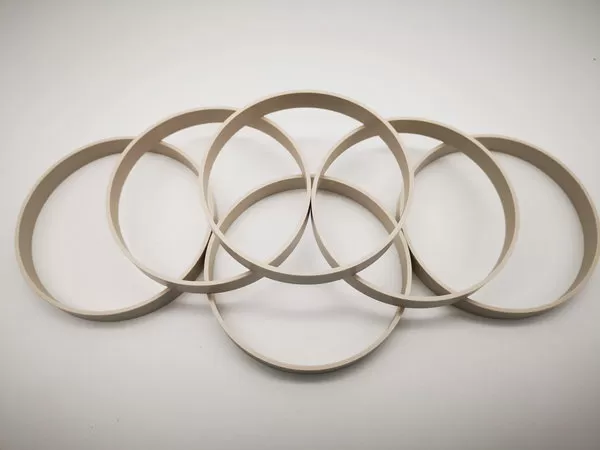

Our PEEK valve seats deliver superior wear resistance, chemical inertness, and thermal stability up to 550°F (288°C). Engineered for demanding high-pressure and high-temperature valve applications, these durable seats reduce friction and extend valve life across oil & gas, aerospace, and chemical industries.

_______________________________________________________________________________________________________________________________________________________________________

PEEK valve seats, made from advanced polyetheretherketone (PEEK) materials including carbon/graphite-filled grades, are engineered to meet the rigorous demands of high-pressure and high-temperature valve applications. With continuous temperature resistance up to 550°F (288°C) and outstanding chemical stability, PEEK seats excel in harsh environments such as oil & gas, aerospace, chemical processing, and industrial fluid control systems.

The inherent toughness and abrasion resistance of PEEK surpass traditional fluoropolymer seats, making them ideal for valves handling slurries, aggressive chemicals, and steam. Carbon fiber or graphite fillers reduce the coefficient of friction, lowering valve operating torque and minimizing wear, which extends service intervals and reduces maintenance costs.

Key Advantages

Exceptional Thermal Stability: Maintains dimensional accuracy and mechanical strength under continuous exposure to elevated temperatures and steam.

Superior Chemical Resistance: Resistant to acids, bases, hydrocarbons, and corrosive media, ensuring long-term durability in aggressive fluids.

High Wear and Abrasion Resistance: Ideal for slurry and high-velocity flow applications, preventing premature seat degradation.

Low Friction Coefficient: Enhances valve efficiency by reducing torque requirements and wear on mating components.

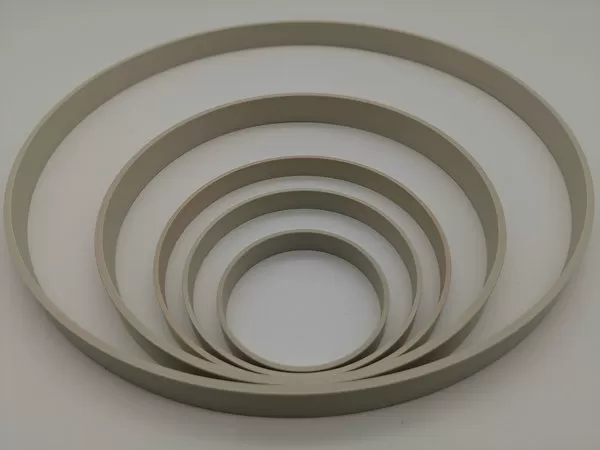

Design Flexibility: Injection molding enables complex geometries and tight tolerances, improving sealing performance and reducing pressure losses.

Flame Retardant and Non-Toxic: Meets UL94 V-0 standards and is suitable for applications requiring chemical inertness and safety.

PEEK valve seats are available in unfilled and reinforced grades, allowing customization to specific application needs. Their dimensional stability and low thermal expansion ensure reliable sealing performance even under fluctuating temperature and pressure conditions.

Widely used in ball valves, hydraulic valves, and compressor valves, PEEK valve seats improve valve reliability and operational efficiency in critical industries such as petrochemical, aerospace, automotive, and power generation.

Choosing PEEK valve seats means investing in advanced polymer technology that delivers long-lasting, corrosion-resistant, and high-performance sealing solutions for the most demanding valve applications.