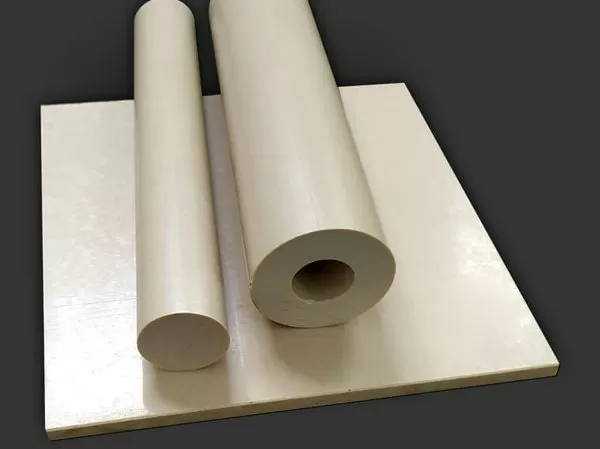

Glass Filled PEEK Properties

The ARKPEEK-GF30 GF30 PEEK Pipe is a 30% glass-fiber reinforced thermoplastic solution designed for mission-critical applications. Combining PEEK’s inherent thermal stability with enhanced rigidity and dimensional precision, these pipes excel in aerospace, automotive, and advanced manufacturing environments.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK-GF30 GF30 PEEK Pipes represent the pinnacle of high-performance thermoplastic engineering, tailored for industries where material failure is not an option. Utilizing a proprietary blend of polyetheretherketone (PEEK) and 30% glass fiber reinforcement, these pipes are engineered to outperform conventional materials in extreme thermal, mechanical, and chemical environments.

Material Advantages

Optimized Reinforcement: 30% glass fiber integration enhances flexural modulus (≥10 GPa) and reduces creep deformation under sustained loads.

Thermal Resilience: Retains structural integrity at continuous service temperatures of 250°C (482°F), with short-term tolerance up to 300°C (572°F).

Chemical Inertness: Resistant to hydrolysis, UV degradation, and aggressive media including hydrocarbons, acids, and alkalis (pH 0–14).

Precision Dimensional Stability: Coefficient of thermal expansion (CTE) of 2.5 x 10⁻⁵/K ensures minimal deviation in high-precision assemblies.

Dielectric Properties: Volume resistivity >10¹⁶ Ω·cm, ideal for electrical insulation in high-voltage applications.

Engineering Specifications

Compliance: Meets ISO 10993 (biocompatibility), UL 94 V-0 (flammability), and ASTM D638 (tensile strength).

Surface Finish: Extruded to Ra ≤0.8 µm for reduced friction in dynamic systems.

Tolerance: Wall thickness uniformity within ±0.1 mm for critical fluid/gas transfer applications.

Industrial Applications

Aerospace & Defense: Fuel line conduits, UAV actuator housings, and engine thermal management systems.

Automotive Electrification: Lightweight structural components for EV battery cooling systems and hydrogen fuel cell manifolds.

Semiconductor Manufacturing: Ultra-clean, particle-resistant tubing for wafer handling and chemical delivery.

Energy Sector: Corrosion-resistant piping for geothermal, offshore drilling, and LNG processing.

Medical Technology: MRI-compatible housings, sterilizable surgical instrumentation, and implantable device guides.

Why Partner With Us?

As a certified GF30 PEEK Pipe supplier, we deliver:

Advanced Extrusion Technology: Proprietary processes ensure void-free, homogenous fiber dispersion.

R&D Collaboration: Custom formulations for enhanced wear resistance, thermal conductivity, or EMI shielding.

Traceability: Full material lot certification, including DSC/TGA analysis reports.

Global Compliance: REACH, RoHS, and FDA-compliant formulations for regulated markets.

_______________________________________________________________________________________________________________________________________________________________________

Material Grades

ARKPEEK-1000: 100%PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

PEEK 30 Glass Filled Tube Size Table

| NO. | Dimension OD*ID (mm) | Weight ( g ) |

| 1 | ∅1.6*∅0.13*1000 | 2.6 |

| 2 | ∅1.6*∅0.25*1000 | 2.5 |

| 3 | ∅1.6*∅0.5*1000 | 2.4 |

| 4 | ∅1.6*∅0.75*1000 | 2.0 |

| 5 | ∅1.6*∅1*1000 | 1.6 |

| 6 | ∅2.33*∅1.6*1000 | 2.9 |

| 7 | ∅2.8*∅2.5*1000 | 1.6 |

| 8 | ∅3*∅2.67*1000 | 1.9 |

| 9 | ∅3.2*∅1*1000 | 9.4 |

| 10 | ∅3.2*∅1.6*1000 | 7.8 |

| 11 | ∅5*∅2.5*1000 | 19.1 |

| 12 | ∅5*∅4.5*1000 | 5.8 |

| 13 | ∅7.5*∅4*1000 | 42.6 |

| 14 | ∅10.2*∅8*1000 | 40.9 |

| 15 | ∅12*∅4*1000 | 81.6 |

| 16 | ∅12.45*∅8.88*1000 | 77.7 |

| 17 | ∅29*∅18*1000 | 527.6 |

| 18 | ∅39*∅31*1000 | 571.5 |

| 19 | ∅80*∅30*1000 | 5612.8 |

| 20 | ∅90*∅40*1000 | 6633.3 |

| 21 | ∅100*∅50*1000 | 7653.8 |

| 22 | ∅110*∅60*1000 | 8674.3 |

| 23 | ∅130*∅60*1000 | 13572.7 |

| 24 | ∅140*∅80*1000 | 13470.6 |

| 25 | ∅160*∅90*1000 | 17858.8 |

| 26 | ∅168*∅132*1000 | 11021.0 |

| 27 | ∅180*∅110*1000 | 20716.2 |

| 28 | ∅190*∅130*1000 | 19593.6 |

| 29 | ∅190*∅140*1000 | 16838.3 |

| 30 | ∅200*∅130*1000 | 23573.6 |

| 31 | ∅220*∅150*1000 | 26431.0 |

| 32 | ∅240*∅170*1000 | 29288.4 |

| 33 | ∅257*∅230*1000 | 13418.6 |

| 34 | ∅250*∅190*1000 | 26941.0 |

| 35 | ∅260*∅210*1000 | 23981.8 |

| 36 | ∅280*∅210*1000 | 35003.2 |

| 37 | ∅280*∅230*1000 | 26022.0 |

| 38 | ∅300*∅250*1000 | 28063.8 |

| 39 | ∅320*∅300*1000 | 12654.2 |

| 40 | ∅340*∅250*1000 | 54188.6 |

| 41 | ∅360*∅280*1000 | 52249.6 |

| 42 | ∅580*∅450*1000 | 136645.0 |