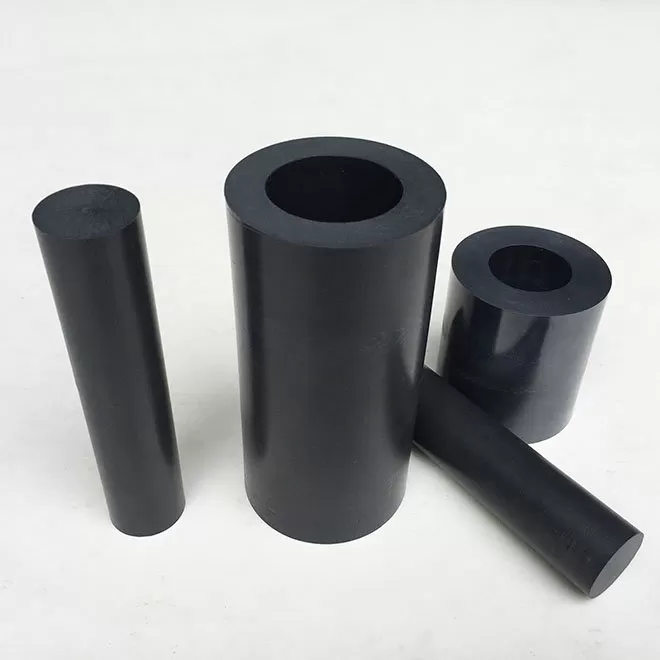

PEEK Carbon-Filled Tubes:

Our PEEK Carbon Filled Pipes combine polyetheretherketone (PEEK) with high carbon fiber reinforcement for unmatched strength, heat resistance, and durability. Ideal for demanding applications in aerospace, oil & gas, and industrial machinery. Trusted PEEK pipe suppliers delivering precision-engineered solutions.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Carbon Filled Pipes are advanced engineering solutions designed to excel in the most challenging environments. Reinforced with carbon fibers, these pipes enhance PEEK’s inherent properties, delivering superior mechanical performance, thermal stability, and resistance to abrasion, chemicals, and high-pressure conditions.

Material Features

High-Strength Design: Carbon fiber reinforcement boosts rigidity, tensile strength, and load-bearing capacity.

Thermal Resistance: Operates continuously at 250°C (482°F) without compromising structural integrity.

Chemical Inertness: Resists acids, hydrocarbons, and aggressive solvents, perfect for chemical processing.

Low Friction & Wear: Ideal for dynamic applications like hydraulic systems, pump components, and bearings.

Lightweight & Corrosion-Resistant: Outperforms metals with a superior strength-to-weight ratio.

Key Applications

Aerospace: Fuel lines, actuator housings, and thermal management systems.

Oil & Gas: Downhole tools, valve components, and corrosion-resistant piping.

Industrial Machinery: Wear-resistant bushings, conveyor systems, and semiconductor equipment.

Automotive: Lightweight replacements for metal in cooling systems and sensor housings.

Chemical Processing: Pipes and fittings for handling corrosive fluids and high-purity applications.

As a leading PEEK Carbon Filled Pipe supplier, we prioritize precision manufacturing to ensure consistent wall thickness, dimensional accuracy, and compliance with industry standards. Our pipes are tailored for seamless integration into high-stress environments, offering longevity and reliability.

Why Choose Our Pipes?

Certified Quality: Meets aerospace (AMS) and industrial specifications.

Custom Solutions: Available in bespoke diameters, lengths, and reinforcement levels.

Technical Expertise: Support for material selection and application optimization.

_______________________________________________________________________________________________________________________________________________________________________

Material Grades

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -30°C to 250°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

Size Table

| NO. | Dimension OD*ID (mm) | Weight ( g ) |

| 1 | ∅1.6*∅0.13*1000 | 2.6 |

| 2 | ∅1.6*∅0.25*1000 | 2.5 |

| 3 | ∅1.6*∅0.5*1000 | 2.4 |

| 4 | ∅1.6*∅0.75*1000 | 2.0 |

| 5 | ∅1.6*∅1*1000 | 1.6 |

| 6 | ∅2.33*∅1.6*1000 | 2.9 |

| 7 | ∅2.8*∅2.5*1000 | 1.6 |

| 8 | ∅3*∅2.67*1000 | 1.9 |

| 9 | ∅3.2*∅1*1000 | 9.4 |

| 10 | ∅3.2*∅1.6*1000 | 7.8 |

| 11 | ∅5*∅2.5*1000 | 19.1 |

| 12 | ∅5*∅4.5*1000 | 5.8 |

| 13 | ∅7.5*∅4*1000 | 42.6 |

| 14 | ∅10.2*∅8*1000 | 40.9 |

| 15 | ∅12*∅4*1000 | 81.6 |

| 16 | ∅12.45*∅8.88*1000 | 77.7 |

| 17 | ∅29*∅18*1000 | 527.6 |

| 18 | ∅39*∅31*1000 | 571.5 |

| 19 | ∅80*∅30*1000 | 5612.8 |

| 20 | ∅90*∅40*1000 | 6633.3 |

| 21 | ∅100*∅50*1000 | 7653.8 |

| 22 | ∅110*∅60*1000 | 8674.3 |

| 23 | ∅130*∅60*1000 | 13572.7 |

| 24 | ∅140*∅80*1000 | 13470.6 |

| 25 | ∅160*∅90*1000 | 17858.8 |

| 26 | ∅168*∅132*1000 | 11021.0 |

| 27 | ∅180*∅110*1000 | 20716.2 |

| 28 | ∅190*∅130*1000 | 19593.6 |

| 29 | ∅190*∅140*1000 | 16838.3 |

| 30 | ∅200*∅130*1000 | 23573.6 |

| 31 | ∅220*∅150*1000 | 26431.0 |

| 32 | ∅240*∅170*1000 | 29288.4 |

| 33 | ∅257*∅230*1000 | 13418.6 |

| 34 | ∅250*∅190*1000 | 26941.0 |

| 35 | ∅260*∅210*1000 | 23981.8 |

| 36 | ∅280*∅210*1000 | 35003.2 |

| 37 | ∅280*∅230*1000 | 26022.0 |

| 38 | ∅300*∅250*1000 | 28063.8 |

| 39 | ∅320*∅300*1000 | 12654.2 |

| 40 | ∅340*∅250*1000 | 54188.6 |

| 41 | ∅360*∅280*1000 | 52249.6 |

| 42 | ∅580*∅450*1000 | 136645.0 |