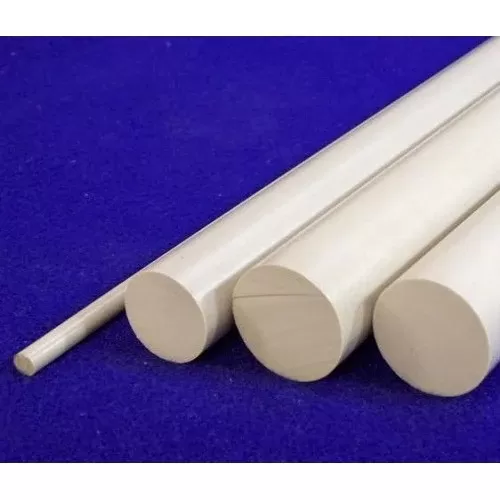

PEEK Material Description

ARKPEEK® PEEK Material delivers unmatched performance in extreme environments. As a leading PEEK material supplier and manufacturer, we provide custom-engineered grades like CF30 (30% carbon fiber), GF30 (30% glass fiber), and MOD (PTFE/graphite-enhanced) with precise PEEK material specifications for thermal stability (up to 260°C), chemical resistance, and mechanical strength. Ideal for aerospace, medical devices, and oil/gas applications. Request competitive PEEK material pricing and technical datasheets tailored to your needs.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK® PEEK Material: Engineered Excellence for Demanding Industries

As a premier PEEK material manufacturer, we also know as PEEKChina who specializes in high-performance polyetheretherketone (PEEK) solutions designed to solve critical engineering challenges. Our ARKPEEK® grades are precision-formulated with unique PEEK material compositions to meet rigorous industrial, medical, and aerospace standards.

Why Choose ARKPEEK®?

Tailored Compositions

ARKPEEK-1000®: 100% virgin PEEK for exceptional chemical/hydrolysis resistance.

ARKPEEK-CF30®: 30% carbon fiber reinforcement for high rigidity and thermal conductivity.

ARKPEEK-GF30®: 30% glass fiber for improved creep strength and dimensional stability.

ARKPEEK-MOD®: PTFE/graphite blend for superior wear resistance and low friction.

Technical Superiority

Mechanical: Tensile strength up to 210 MPa (CF30), compressive strength up to 240 MPa.

Thermal: Continuous use at 260°C, UL94 V-0 flame retardancy.

Electrical: Dielectric strength up to 19 kV/mm (GF30), ideal for insulating components.

Cost Efficiency: Optimize your PEEK material cost with grades that reduce wear, maintenance, and downtime.

Solve Industry-Specific Challenges

Medical: Biocompatible, sterilizable PEEK for surgical tools and implants.

Aerospace: Lightweight, high-strength components resistant to jet fuels and extreme temps.

Semiconductors: Ultra-clean, static-free material for contamination-sensitive processes.

Oil & Gas: Replace metals with corrosion-resistant PEEK valves/pumps for sour gas environments.

Request Custom Specifications & Pricing

Whether you need standard PEEK material specifications or a custom blend, our team provides:

Detailed technical datasheets (mechanical, thermal, electrical performance).

Competitive PEEK material price quotes with bulk order discounts.

Global logistics support, including HS code documentation.

Partner With a Trusted Manufacturer

With ISO-certified production and rapid prototyping, we ensure your PEEK material meets exact application requirements. Explore our ARKPEEK® portfolio or contact us at sales@peekchina.com for samples, quotes, and engineering support.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Material Composition

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.