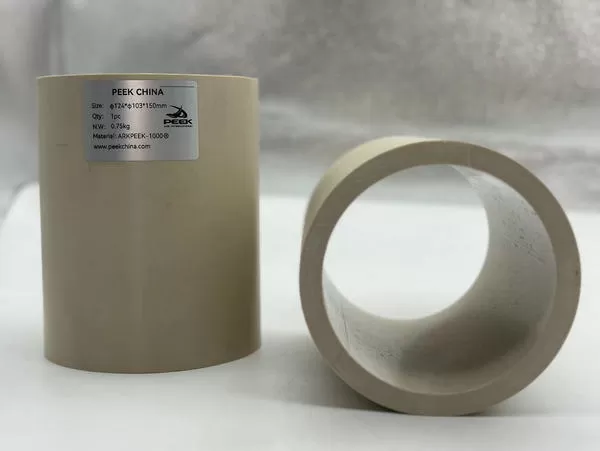

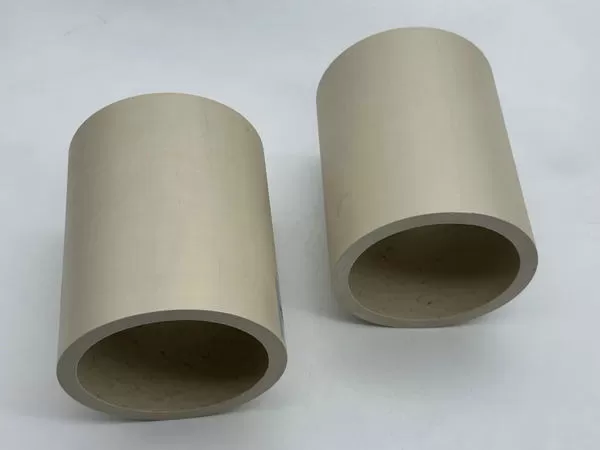

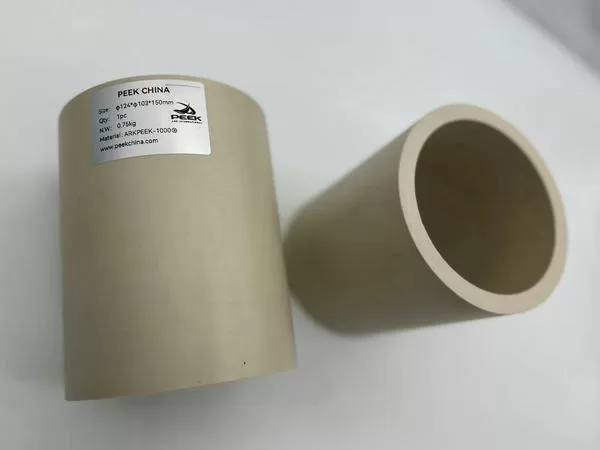

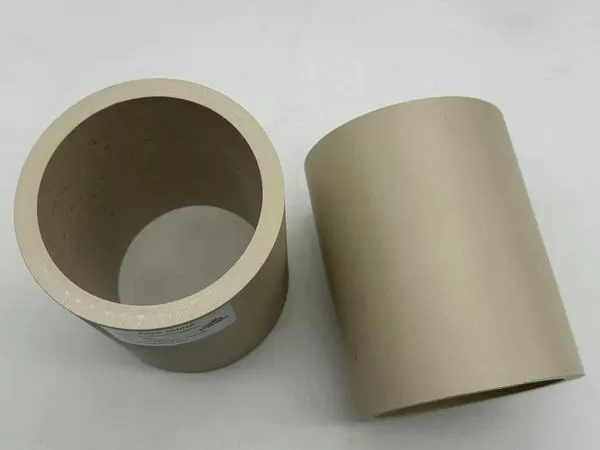

Our custom PEEK pipes are specifically engineered for high-precision machining, making them the ideal choice for manufacturing seals and sealing materials. Known for their exceptional thermal stability, chemical resistance, and mechanical strength, these PEEK pipes offer unparalleled performance in demanding industrial applications. Whether you’re producing seals for automotive, aerospace, or medical devices, our custom PEEK pipes ensure consistent quality and durability, even in extreme conditions.

Custom PEEK pipes are a cornerstone in the manufacturing of high-quality seals and sealing materials, designed to meet the rigorous demands of modern industry. Polyether Ether Ketone (PEEK) is renowned for its exceptional properties, making it the material of choice for applications where durability, chemical resistance, and thermal stability are paramount. Our custom PEEK pipes are precision-engineered to provide unmatched performance in environments where other materials might fail.

These pipes are extensively used in machining processes to create seals and sealing components that require exacting standards. The inherent properties of PEEK, such as its high mechanical strength, low coefficient of friction, and excellent wear resistance, make it particularly suitable for applications in automotive, aerospace, oil and gas, and medical devices. Whether your needs involve withstanding high temperatures, exposure to aggressive chemicals, or maintaining performance under heavy loads, our custom PEEK pipes offer the reliability and longevity you demand.

Beyond their physical properties, custom PEEK pipes are also valued for their versatility. They can be easily machined into complex shapes and sizes, allowing for the production of custom seals and components that fit perfectly into your specific applications. This adaptability ensures that you can achieve the exact specifications required for your project, whether it involves sealing components in pumps, valves, or medical implants.

In addition to their functional benefits, our custom PEEK pipes also contribute to reducing maintenance costs and downtime. The durability and resilience of PEEK mean that seals and components made from this material have a longer service life, reducing the need for frequent replacements and repairs. This long-term performance translates into significant cost savings and increased operational efficiency for your business.

In summary, custom PEEK pipes are an essential solution for any industry that requires high-performance sealing materials. With their superior resistance to extreme conditions and the ability to be machined into precise, durable components, our PEEK pipes are the ideal choice for ensuring the success of your most demanding projects.

What is PEEK pipe? / What is a PEEK tube?

PEEK Pipe is a high-strength, high-temperature thermoplastic with superior mechanical and chemical properties that are ideal for machining and demanding applications.

What is PEEK tubing made of?

Polyether Ether-Ketone (PEEK) is an engineering grade thermoplastic polymer with characteristics that are uniquely suited to many medical tubing applications. PEEK is a high purity, semi-crystalline, organic polymer with excellent resistance to thermal degradation at high temperatures.

What are the properties of virgin PEEK?

Cilck HERE and find the material ARKPEEK-1000®.