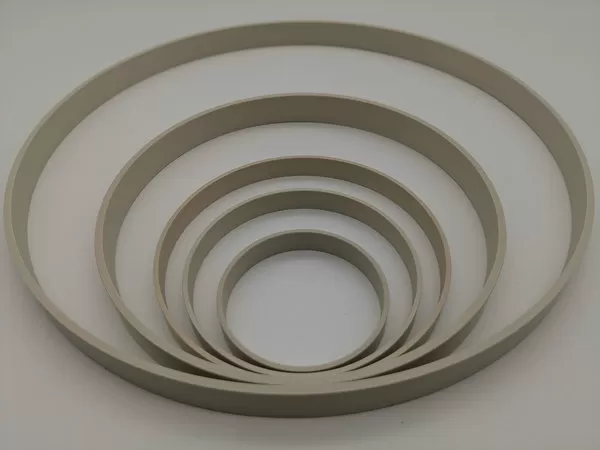

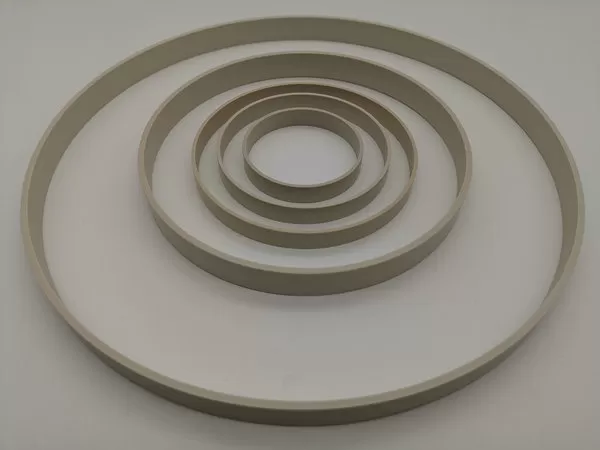

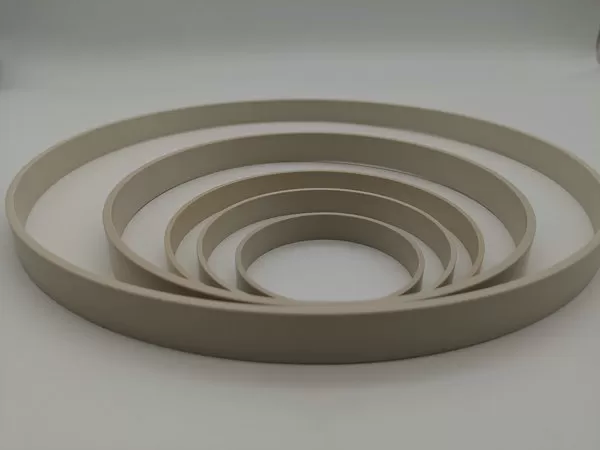

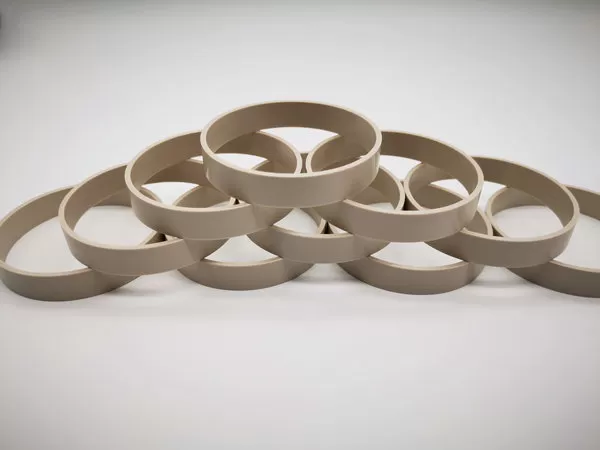

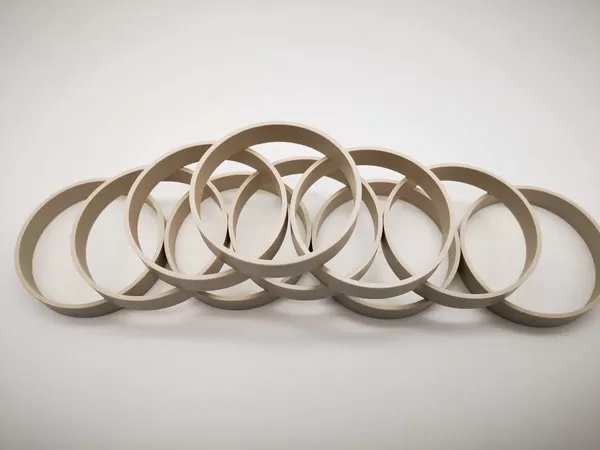

PEEK Ring

PEEK Rings are precision-engineered for extreme industrial applications. Choose from popular styles—piston rings, sealing rings, bearing rings, thrust washers, and spacers—crafted from ARKPEEK® to withstand 260°C heat, corrosive chemicals, and heavy loads. Solve leakage, friction, and insulation challenges in oil/gas, automotive, and medical industries. Custom sizes and grades (GF30, CF30, MOD, 1000) available.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Rings: Specialized Styles for Critical Industrial Applications

From high-speed piston rings to corrosion-resistant seals, ARKPEEK® PEEK Rings are engineered to outperform metals and standard polymers in the most demanding environments. Available in multiple styles and formulations, these rings deliver unmatched reliability for industries prioritizing longevity and precision.

Popular Ring Styles & Applications

| Ring Styles | Use Case | Benefits |

| PEEK Piston Rings | High-temperature engines, compressors, and hydraulic systems. | Low friction, reduced wear on cylinder walls, and thermal stability up to 260°C. |

| PEEK Sealing Rings | Chemical pumps, oil/gas valves, and pharmaceutical reactors. | Resistant to acids, sour gas, and steam. UL94 V-0 flammability rating. |

| PEEK Bearing Rings | High-load bearings in robotics, turbines, and conveyor systems. | ARKPEEK-CF30® (30% carbon fiber) enhances rigidity and load capacity. |

| PEEK Spacer Rings | Electrical insulators in power plants, semiconductor equipment. | High dielectric strength (19 kV/mm) and dimensional stability. |

| PEEK Wear Rings | Hydraulic cylinders, offshore drilling equipment. | 50% longer lifespan than PTFE, even under abrasive conditions. |

| PEEK Thrust Washers | Automotive transmissions, aerospace actuators. | Low friction and high compressive strength (up to 240 MPa). |

| PEEK Backup Rings | Support for elastomeric seals in extreme-pressure systems. | Prevents extrusion in pressures up to 300 bar. |

| PEEK Insulator Rings | High-voltage electrical systems, EV battery housings. | Non-conductive, flame-retardant, and lightweight. |

Why ARKPEEK® Rings Outperform Competitors

Material Versatility: Choose from 4 ARKPEEK® grades (GF30, CF30, MOD, 1000) for tailored performance.

Custom Geometry: Specify ID/OD (10mm–500mm), cross-sections (rectangular, tapered), and surface finishes.

Certifications: ISO 9001, FDA (for ARKPEEK-1000®), and RoHS compliance.

Technical Specifications

Temperature Range: -70°C to +260°C (continuous).

Pressure Tolerance: Up to 300 bar (thrust washers/seals).

Key Metrics:

Tensile Strength: 90–210 MPa.

Dielectric Strength: Up to 19 kV/mm (GF30).

Friction Coefficient: As low as 0.18 (MOD grade).

_______________________________________________________________________________________________________________________________________________________________________

Material Grades

ARKPEEK-1000: 100%PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.