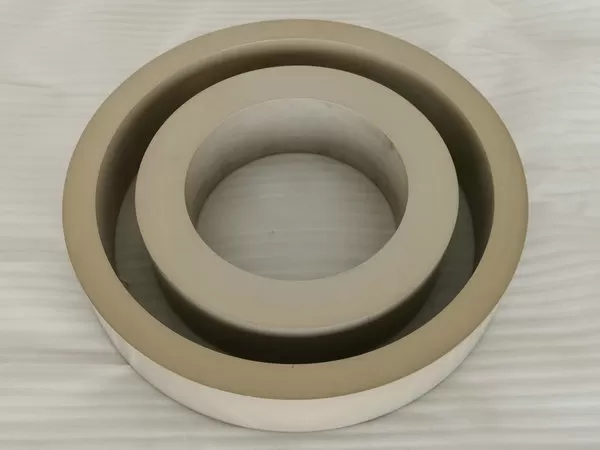

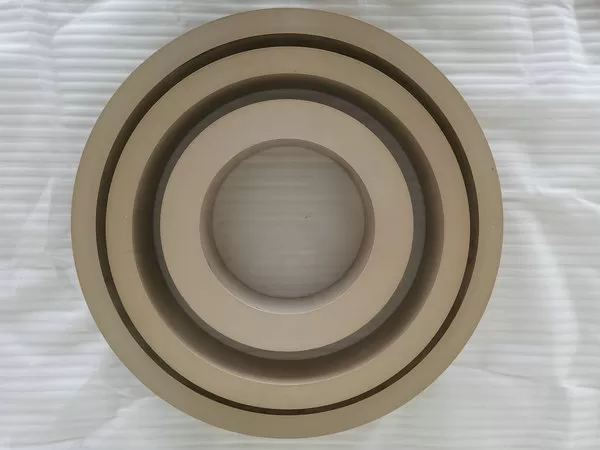

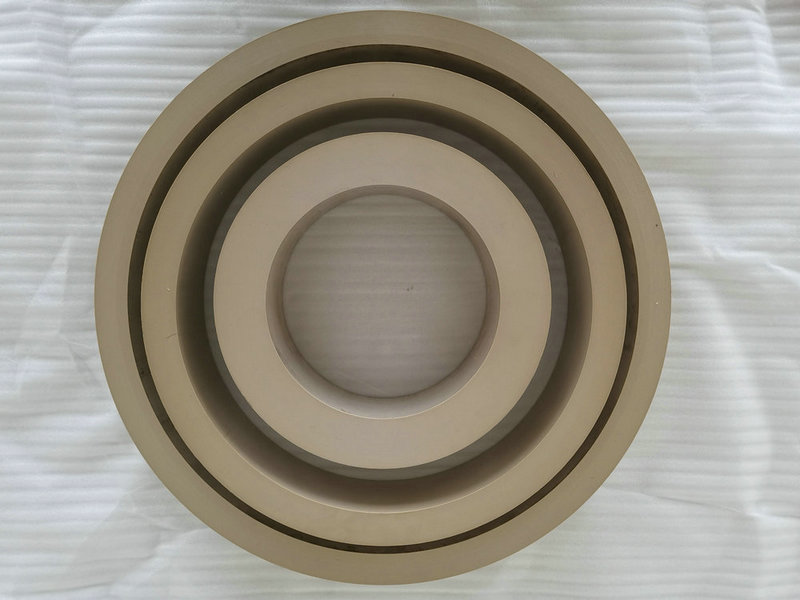

PEEK Seal Material

ARKPEEK Sealing Material offers unmatched chemical resistance, thermal stability (up to 260°C), and low friction for high-stress environments. Ideal for PEEK sealing rings, valves, and seals, this premium material eliminates leaks in aerospace, automotive, and chemical processing systems. Trusted by leading PEEK sealing material manufacturers, ARKPEEK ensures reliability, longevity, and cost savings.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK PEEK Sealing Material – Engineered for Extreme Performance

Struggling with seal failures in high-temperature or corrosive environments? ARKPEEK’s PEEK Sealing Material provides a robust solution for industries demanding precision, durability, and leak-free operation.

Key Technical Properties

Thermal Stability: Operates continuously at 260°C (500°F) with minimal deformation.

Chemical Resistance: Withstands acids, hydrocarbons, and steam, outperforming PTFE and rubber.

Low Friction & Wear: PEEK sealing rings reduce energy loss and maintenance costs.

High Mechanical Strength: Maintains integrity under 20,000+ psi pressure (heavy-wall PEEK tube compatibility).

Applications & Uses

PEEK Sealing Rings: For pumps, compressors, and hydraulic systems in oil/gas and aerospace.

Valve Seat Material: Resists wear in high-cycle industrial valves.

Semiconductor Manufacturing: Ultra-clean, vacuum-rated seals for contamination-sensitive processes.

Automotive: Turbocharger seals, fuel systems, and EV battery insulation.

Why ARKPEEK is the Best PEEK Material for Sealing?

Custom Solutions: Tailored PEEK seal material grades (e.g., carbon-fiber reinforced for abrasion resistance).

Certified Quality: ISO 9001-compliant manufacturing for consistent performance.

Cost Efficiency: Extended service life reduces downtime and replacement costs.

Partner with Trusted PEEK Sealing Material Suppliers

As leading PEEK sealing material manufacturers, ARKPEEK provides:

Technical Support: Optimize seal design for your application.

Rapid Prototyping: Test PEEK seat material in real-world conditions.

Global Delivery: Reliable supply chain for bulk orders.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK Sealing Material Grades

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Tube's Size For Sealing Machining

| NO. | Dimension OD*ID (mm) | Weight ( g ) |

| 1 | ∅1.6*∅0.13*1000 | 2.6 |

| 2 | ∅1.6*∅0.25*1000 | 2.5 |

| 3 | ∅1.6*∅0.5*1000 | 2.4 |

| 4 | ∅1.6*∅0.75*1000 | 2.0 |

| 5 | ∅1.6*∅1*1000 | 1.6 |

| 6 | ∅2.33*∅1.6*1000 | 2.9 |

| 7 | ∅2.8*∅2.5*1000 | 1.6 |

| 8 | ∅3*∅2.67*1000 | 1.9 |

| 9 | ∅3.2*∅1*1000 | 9.4 |

| 10 | ∅3.2*∅1.6*1000 | 7.8 |

| 11 | ∅5*∅2.5*1000 | 19.1 |

| 12 | ∅5*∅4.5*1000 | 5.8 |

| 13 | ∅7.5*∅4*1000 | 42.6 |

| 14 | ∅10.2*∅8*1000 | 40.9 |

| 15 | ∅12*∅4*1000 | 81.6 |

| 16 | ∅12.45*∅8.88*1000 | 77.7 |

| 17 | ∅29*∅18*1000 | 527.6 |

| 18 | ∅39*∅31*1000 | 571.5 |

| 19 | ∅80*∅30*1000 | 5612.8 |

| 20 | ∅90*∅40*1000 | 6633.3 |

| 21 | ∅100*∅50*1000 | 7653.8 |

| 22 | ∅110*∅60*1000 | 8674.3 |

| 23 | ∅130*∅60*1000 | 13572.7 |

| 24 | ∅140*∅80*1000 | 13470.6 |

| 25 | ∅160*∅90*1000 | 17858.8 |

| 26 | ∅168*∅132*1000 | 11021.0 |

| 27 | ∅180*∅110*1000 | 20716.2 |

| 28 | ∅190*∅130*1000 | 19593.6 |

| 29 | ∅190*∅140*1000 | 16838.3 |

| 30 | ∅200*∅130*1000 | 23573.6 |

| 31 | ∅220*∅150*1000 | 26431.0 |

| 32 | ∅240*∅170*1000 | 29288.4 |

| 33 | ∅257*∅230*1000 | 13418.6 |

| 34 | ∅250*∅190*1000 | 26941.0 |

| 35 | ∅260*∅210*1000 | 23981.8 |

| 36 | ∅280*∅210*1000 | 35003.2 |

| 37 | ∅280*∅230*1000 | 26022.0 |

| 38 | ∅300*∅250*1000 | 28063.8 |

| 39 | ∅320*∅300*1000 | 12654.2 |

| 40 | ∅340*∅250*1000 | 54188.6 |

| 41 | ∅360*∅280*1000 | 52249.6 |

| 42 | ∅580*∅450*1000 | 136645.0 |