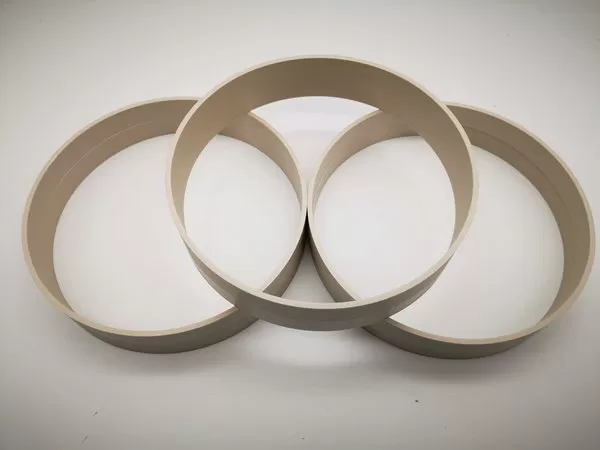

PEEK Sealing Plastic

6-Inch ARKPEEK® PEEK Seals are engineered for precision sealing in compact, high-stress systems. Part of our 3-inch to 28-inch size range, these seals use advanced grades—virgin PEEK (1000), glass fiber (GF30), carbon fiber (CF30), and PTFE/graphite/carbon (MOD)—to resist extreme pressure (500 bar), abrasive media, and aggressive chemicals. Perfect for semiconductor tools, lab equipment, and miniaturized hydraulics. Solve micro-leaks and wear.

_______________________________________________________________________________________________________________________________________________________________________

6-Inch ARKPEEK® PEEK Seals: Micro-Precision, Macro Performance

In applications where space is limited but reliability is non-negotiable, 6-Inch ARKPEEK® PEEK Seals deliver unmatched performance. Designed for compact systems requiring exacting tolerances, these seals excel in high-cycling, high-pressure, and chemically hostile environments. Available in sizes from 3-inch to 28-inch, they’re the go-to solution for industries demanding precision at scale.

Material Grades & Targeted Performance

ARKPEEK-1000® (Virgin PEEK):

Ultra-Pure Sealing: FDA-compliant for lab equipment, biopharma pumps, and ultrapure fluid systems.

Chemical Resistance: Resists acids, ketones, and solvents without leaching.

ARKPEEK-GF30® (30% Glass Fiber):

Zero Creep: Maintains tight seals in cyclic thermal environments (e.g., semiconductor wafer handling).

Applications: Miniature steam valves, precision actuators.

ARKPEEK-CF30® (30% Carbon Fiber):

Strength in Miniature: Withstands 500+ bar pressure in compact hydraulic systems.

Static Dissipation: Critical for explosive environments (ATEX/IECEx compliance).

ARKPEEK-MOD® (PTFE/Graphite/Carbon Blend):

Frictionless Motion: Coefficient as low as 0.12 for high-cycle robotic arms or dosing pumps.

Abrasion Resistance: Ideal for gritty media in micro-scale slurry systems.

Why 6-Inch ARKPEEK® Seals?

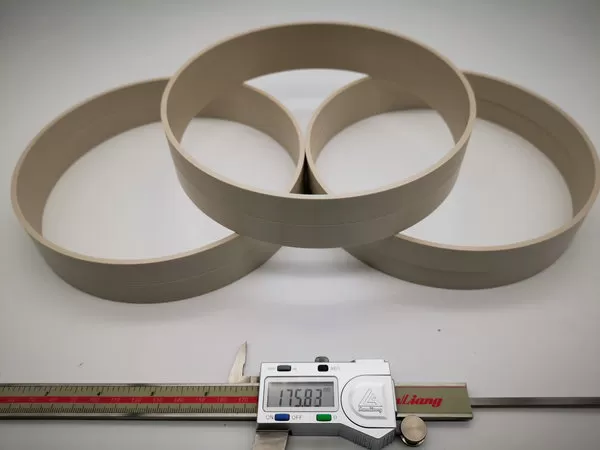

Precision Engineering: Tolerance of ±0.02mm for leak-free performance in microfluidic and lab systems.

Compact Durability: 2x lifespan of PTFE seals in high-frequency applications (e.g., pneumatic valves).

Customization: Thin cross-sections (down to 1.5mm), grooves, or multi-lip designs.

Industry-Specific Solutions

Semiconductor Manufacturing: 1000-grade seals for ultrapure gas/chemical delivery systems.

Laboratory Equipment: MOD-grade seals for corrosive solvent dosing pumps.

Compact Hydraulics: CF30 seals for mini excavators or drone landing gear systems.

Pharma Automation: GF30 seals for sterile filling machines.

Technical Specifications

Size: 6-inch nominal diameter (3"-28" custom sizes).

Pressure Rating: 200–500 bar (grade-dependent).

Temperature Range: -70°C to +260°C (continuous).

Key Metrics:

Surface Finish: Ra <0.4µm (mirror polish optional).

Cycle Life: 1M+ cycles (MOD/CF30 grades).

Flammability: UL94 V-0 (all grades).

Solve Micro-Scale Challenges

Eliminate Micro-Leaks: Precision-machined for hermetic sealing in nanotech applications.

Reduce Maintenance: 60% fewer replacements vs. rubber seals.

Rapid Prototyping: 72-hour turnaround for custom 6-inch seals.

Upgrade to Precision Sealing

From semiconductor fabs to lab-scale reactors, our 6-inch PEEK seals ensure reliability in the tightest spaces. Request a quote, sample, or technical consultation today—global shipping and ISO 9001 quality guaranteed!