PEEK Seat Material Properties

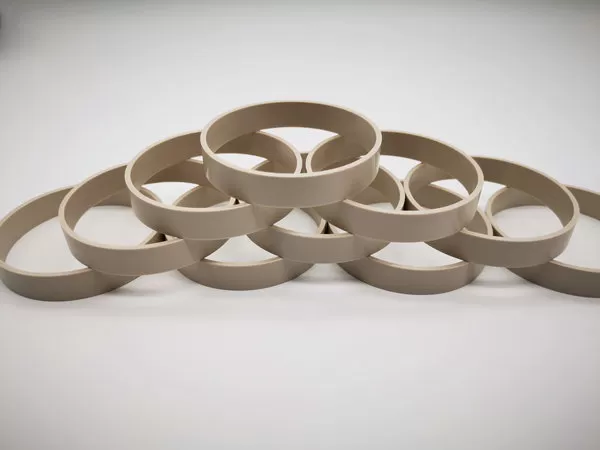

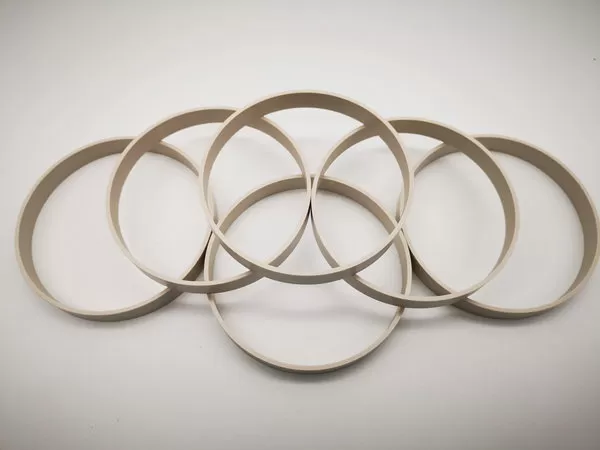

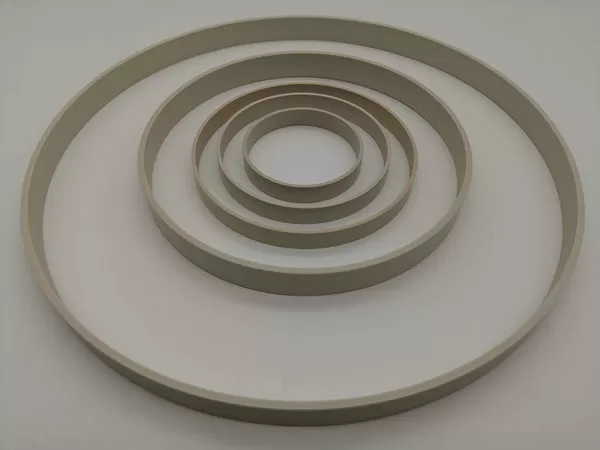

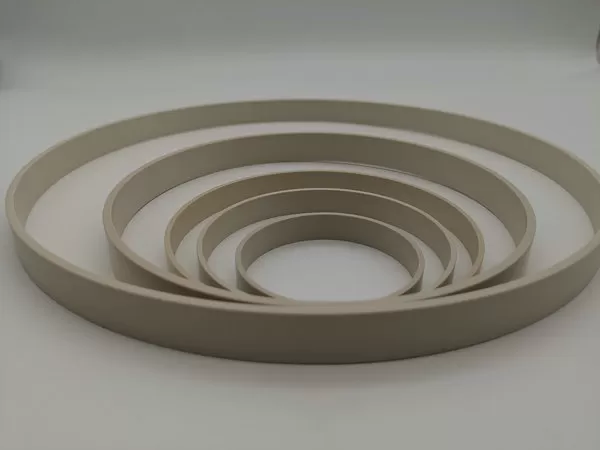

ARKPEEK® PEEK Seats are engineered to outperform metal and PTFE in extreme environments. With a temperature range of -70°C to 260°C and unmatched chemical resistance (see our PEEK seat material compatibility chart), these seats eliminate leaks, corrosion, and wear in industrial valves. Ideal for oil/gas, chemical, and power industries. Custom sizes and grades (1000, CF30, GF30, MOD).

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK® PEEK Seats: Revolutionizing Valve Performance in Extreme Conditions

In industries where valve failure is not an option, ARKPEEK® PEEK Seats deliver unmatched reliability. Designed to replace traditional metal, rubber, or PTFE seats, these precision-engineered components solve critical challenges like leakage, corrosion, and thermal degradation.

Why ARKPEEK® PEEK Seats?

Unrivaled Temperature Resistance:

Operate continuously from -70°C to 260°C (short-term peaks up to 310°C).

Perfect for steam systems, geothermal plants, and high-temperature processing.

Chemical Compatibility:

Resistant to acids, hydrocarbons, sour gas, and solvents.

Contact for our PEEK seat material compatibility chart for detailed chemical resistance data.

Wear & Abrasion Resistance:

3x longer lifespan than PTFE seats, even in high-cycle applications.

Material Flexibility

ARKPEEK-1000®: Virgin PEEK for chemical purity and FDA compliance.

ARKPEEK-CF30®: Carbon fiber-reinforced for high load-bearing capacity.

ARKPEEK-GF30®: 30% glass fiber-enhanced for superior rigidity and dimensional stability in high-load/high-temperature environments.

ARKPEEK-MOD®: PTFE/graphite/carbon blend for ultra-low friction and stick-slip prevention.

Applications & Industries

Oil & Gas:

Corrosion-resistant seats for wellhead valves, choke valves, and pipeline systems.

Resists H₂S, CO₂, and brine in offshore drilling.

Chemical Processing:

Handles sulfuric acid, chlorine, and caustic solutions in reactor feed valves.

Power Generation:

Steam turbine valves and geothermal energy systems.

Pharmaceuticals:

FDA-compliant seats for sterile processing and CIP/SIP systems.

Technical Specifications

Temperature Range: -70°C to +260°C (continuous) | Peak: 310°C.

Pressure Rating: Up to 420 bar (6,000 psi) depending on valve design.

Key Metrics

Tensile Strength: 90–210 MPa (grade-dependent).

Flammability: UL94 V-0 certified.

Friction Coefficient: As low as 0.18 (MOD grade).

Solve Your Valve Challenges

Leakage Prevention: Tight sealing even after 100,000+ cycles.

Cost Savings: Reduce downtime and maintenance costs by 40%.

Custom Solutions

Tailored dimensions (OD/ID, thickness).

Grooved designs or integrated backup rings.

Request Your Free Compatibility Chart

Ask our PEEK seat material compatibility chart to verify resistance to your specific chemicals or request a custom quote. Global shipping, ISO 9001 certified, and bulk discounts available!

_______________________________________________________________________________________________________________________________________________________________________

Material Grades

ARKPEEK-1000: 100%PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.