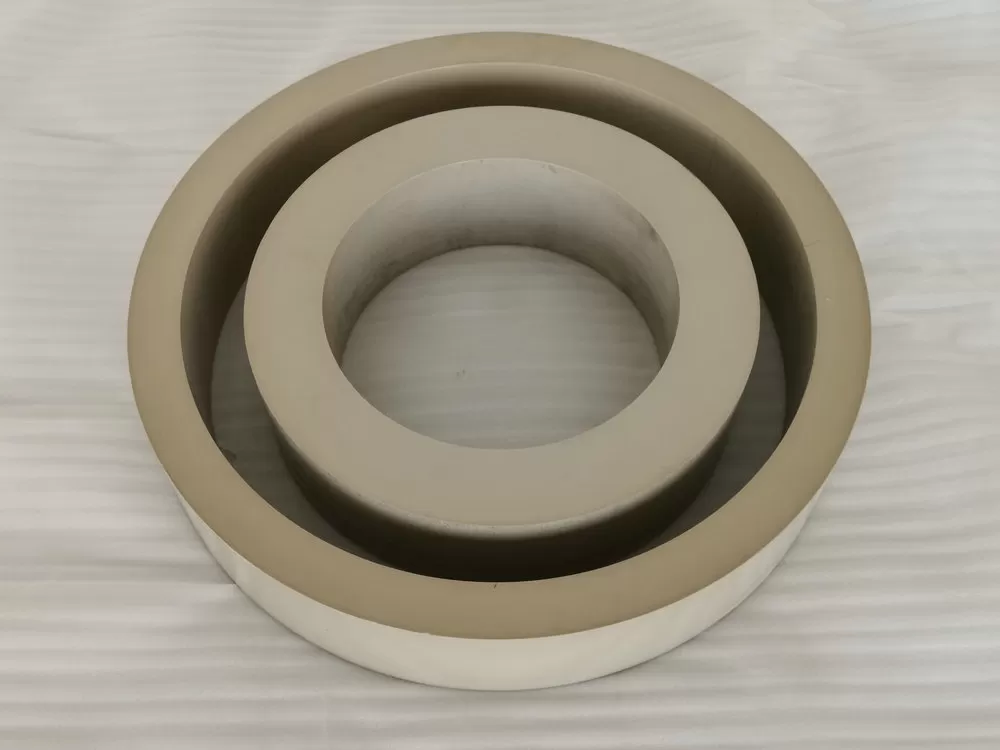

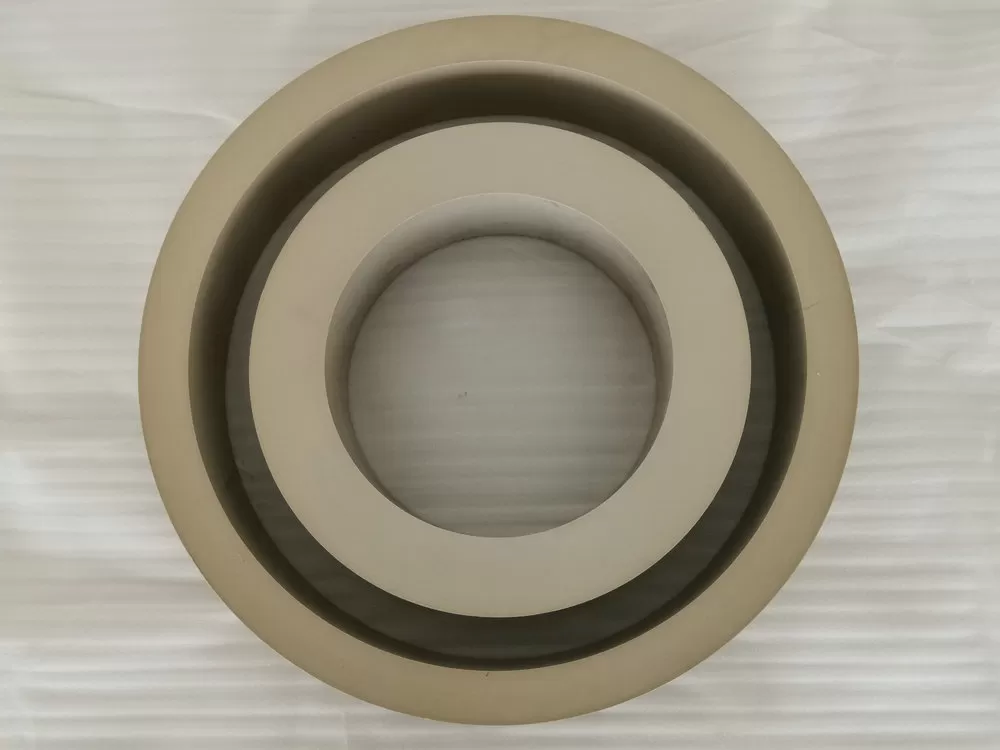

Big Size Tube of PEEK

Big Size PEEK Tubes are designed for demanding industrial applications requiring precision, durability, and flawless fluid transfer. Available in large PEEK tube sizes (custom OD/ID upon request), these tubes excel in high-temperature (up to 260°C), corrosive, and high-pressure environments. Perfect for oil/gas pipelines, chemical processing, and medical fluid systems. As a leading PEEK tube manufacturer, we provide ISO-certified ARKPEEK® material with low friction and superior machinability. Solve leaks, contamination, and wear—request pricing and technical specs now.

_______________________________________________________________________________________________________________________________________________________________________

Introduction to Big Size PEEK Tubes

PEEK (Polyether Ether Ketone) tubes are renowned for their exceptional mechanical properties, thermal stability, and chemical resistance, making them a preferred choice for large-scale industrial applications. Our big size PEEK tubes are designed to meet the demands of machining into complex components, particularly in industries requiring high-performance materials.

Technical Properties of Big Size PEEK Tubes

High Mechanical Strength: Offers superior strength and stiffness, making it ideal for structural components.

Thermal Stability: Maintains its mechanical properties at high temperatures, up to 260°C (480°F).

Chemical Resistance: Highly resistant to acids, solvents, and oils, ensuring durability in aggressive environments.

Low Friction: Exhibits a low coefficient of friction, reducing wear and tear in dynamic applications.

Radiation Resistance: Can withstand high energy radiation, making it suitable for applications requiring sterilization.

PEEK Tube Sizes and Machining Applications

Our big size PEEK tubes are available in various dimensions, including large diameters, to cater to diverse machining needs. These tubes are ideal for post-processing into components such as seals, gaskets, and bearings, particularly in the oil and gas industry. The large dimensions allow for the creation of complex parts with precise tolerances, making them the best PEEK pipe for machining.

Applications of Big Size PEEK Tubes

Oil and Gas Industry: Used for components requiring high chemical resistance and mechanical strength, such as seals and gaskets.

Aerospace and Automotive: Employed in components that require lightweight yet strong materials, such as valve components and piston parts.

Medical Devices: Utilized in surgical instruments and implants for its biocompatibility and resistance to sterilization processes.

Industrial Manufacturing: Ideal for machining into parts like bearings, bushings, and wear pads due to its wear resistance and dimensional stability.

Our big size PEEK tubes are designed to solve engineering challenges in demanding environments, providing durable solutions that enhance performance and reliability across multiple industries. Whether you're looking for large size PEEK pipe options or seeking a supplier for long-term partnerships, we provide flexible solutions to meet your needs.

Why Choose Us?

Customization Options: We offer customizable material blends and dimensions to fit specific application needs.

Quality Assurance: Our products meet international standards for quality and performance.

Competitive Pricing: We provide competitive pricing without compromising on quality.

Expertise: Our team has extensive experience in manufacturing high-performance PEEK tubes for industrial applications.

By choosing our big size PEEK tubes, you can ensure that your industrial components meet the highest standards of performance and durability.

_______________________________________________________________________________________________________________________________________________________________________

Below PEEK Grades Available

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -30°C to 250°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Tube Dimensions

| NO. | Dimension OD*ID (mm) | Weight ( g ) |

| 1 | ∅1.6*∅0.13*1000 | 2.6 |

| 2 | ∅1.6*∅0.25*1000 | 2.5 |

| 3 | ∅1.6*∅0.5*1000 | 2.4 |

| 4 | ∅1.6*∅0.75*1000 | 2.0 |

| 5 | ∅1.6*∅1*1000 | 1.6 |

| 6 | ∅2.33*∅1.6*1000 | 2.9 |

| 7 | ∅2.8*∅2.5*1000 | 1.6 |

| 8 | ∅3*∅2.67*1000 | 1.9 |

| 9 | ∅3.2*∅1*1000 | 9.4 |

| 10 | ∅3.2*∅1.6*1000 | 7.8 |

| 11 | ∅5*∅2.5*1000 | 19.1 |

| 12 | ∅5*∅4.5*1000 | 5.8 |

| 13 | ∅7.5*∅4*1000 | 42.6 |

| 14 | ∅10.2*∅8*1000 | 40.9 |

| 15 | ∅12*∅4*1000 | 81.6 |

| 16 | ∅12.45*∅8.88*1000 | 77.7 |

| 17 | ∅29*∅18*1000 | 527.6 |

| 18 | ∅39*∅31*1000 | 571.5 |

| 19 | ∅80*∅30*1000 | 5612.8 |

| 20 | ∅90*∅40*1000 | 6633.3 |

| 21 | ∅100*∅50*1000 | 7653.8 |

| 22 | ∅110*∅60*1000 | 8674.3 |

| 23 | ∅130*∅60*1000 | 13572.7 |

| 24 | ∅140*∅80*1000 | 13470.6 |

| 25 | ∅160*∅90*1000 | 17858.8 |

| 26 | ∅168*∅132*1000 | 11021.0 |

| 27 | ∅180*∅110*1000 | 20716.2 |

| 28 | ∅190*∅130*1000 | 19593.6 |

| 29 | ∅190*∅140*1000 | 16838.3 |

| 30 | ∅200*∅130*1000 | 23573.6 |

| 31 | ∅220*∅150*1000 | 26431.0 |

| 32 | ∅240*∅170*1000 | 29288.4 |

| 33 | ∅257*∅230*1000 | 13418.6 |

| 34 | ∅250*∅190*1000 | 26941.0 |

| 35 | ∅260*∅210*1000 | 23981.8 |

| 36 | ∅280*∅210*1000 | 35003.2 |

| 37 | ∅280*∅230*1000 | 26022.0 |

| 38 | ∅300*∅250*1000 | 28063.8 |

| 39 | ∅320*∅300*1000 | 12654.2 |

| 40 | ∅340*∅250*1000 | 54188.6 |

| 41 | ∅360*∅280*1000 | 52249.6 |

| 42 | ∅580*∅450*1000 | 136645.0 |