PEEK Seal Material Properties

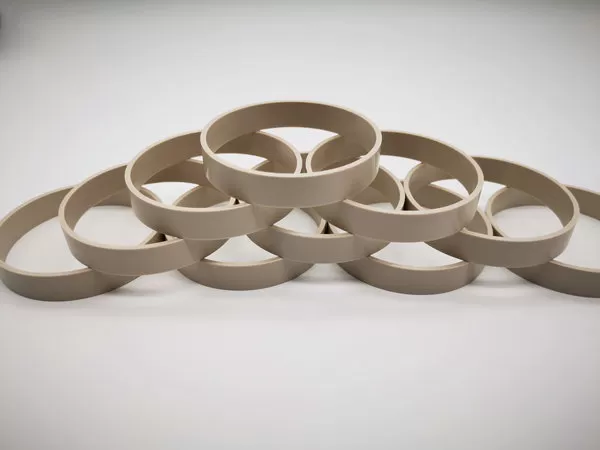

2-Inch ARKPEEK® PEEK Seals are precision-engineered for demanding sealing systems like valve seat inserts and compact hydraulics. Available in four specialized grades—virgin PEEK (1000), glass fiber (GF30), carbon fiber (CF30), and PTFE/graphite/carbon (MOD)—these seals excel in extreme pressure (500 bar), corrosive chemicals, and abrasive environments. Perfect for oil/gas valves, chemical dosing systems, and industrial machinery.

_______________________________________________________________________________________________________________________________________________________________________

2-Inch ARKPEEK® PEEK Seals: Precision Sealing for Critical Industrial Systems

Designed for applications requiring compact yet robust sealing solutions, 2-Inch ARKPEEK® PEEK Seals deliver unmatched reliability in high-stress environments. These seals are ideal for valve seat inserts, hydraulic systems, and machinery where precision and durability are non-negotiable.

Material Grades & Performance Advantages

ARKPEEK-1000® (Virgin PEEK):

Chemical Purity: FDA-compliant for food/pharma and ultrapure fluid systems.

Resistance: Impervious to acids, solvents, and hydrocarbons.

ARKPEEK-GF30® (30% Glass Fiber):

Dimensional Stability: Maintains seal integrity under thermal cycling and heavy loads.

Applications: Steam valves, high-temperature seat inserts.

ARKPEEK-CF30® (30% Carbon Fiber):

High Strength: Withstands 500+ bar pressure; ideal for hydraulic systems and compressors.

Static Dissipation: Safe for explosive environments (ATEX/IECEx).

ARKPEEK-MOD® (PTFE/Graphite/Carbon Blend):

PTFE: Ultra-low friction (µ=0.10) for smooth valve operation.

Graphite: Self-lubricating for dry-running conditions.

Carbon Fiber: Abrasion-resistant for gritty media.

Triple Reinforcement:

Applications: Seat inserts in slurry pumps, chemical reactors.

Why 2-Inch ARKPEEK® Seals?

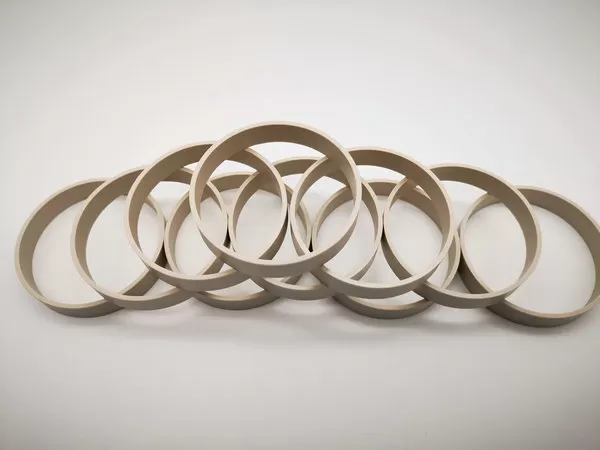

Compact & Robust: Optimized for tight spaces in valves, pumps, and hydraulic systems.

Extreme Durability: Operates at -70°C to 260°C and 500 bar (MOD/CF30 grades). 3x lifespan vs. PTFE seals in abrasive conditions.

Custom Designs: Tailored cross-sections (O-ring, T-seal) and backup ring integration.

Industry Applications

Oil & Gas: MOD-grade seat inserts for choke valves and hydraulic fracturing equipment.

Chemical Processing: 1000-grade seals for corrosive acid dosing systems.

Water Treatment: GF30 seals for chlorination valve seat inserts.

Industrial Machinery: CF30 seals for high-pressure hydraulic cylinders.

Technical Specifications

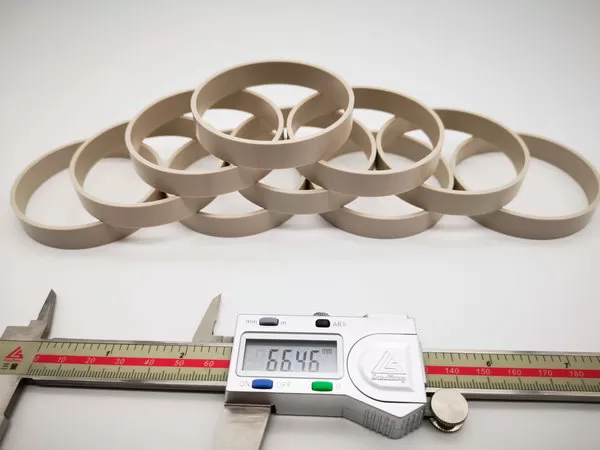

Size: 2-inch nominal diameter (custom sizes 3"-28").

Pressure Rating: 200–500 bar (grade-dependent).

Temperature Range: -70°C to +260°C (continuous).

Key Metrics:

Tensile Strength: 90 MPa (1000) to 210 MPa (CF30).

Flammability: UL94 V-0 (all grades).

Cycle Life: 500,000+ cycles (MOD/CF30).

Solve Your Sealing Challenges

Leak-Free Guarantee: Precision-machined for hermetic sealing in critical systems.

Cost Savings: 50% fewer replacements vs. metal/elastomer seals.

Fast Turnaround: Prototyping in 5 days; bulk orders in 2 weeks.

Upgrade to ARKPEEK® Seals

From valve seat inserts to hydraulic systems, our 2-inch PEEK seals ensure reliability in the toughest environments. Request a quote, sample, or technical specs today—global shipping and ISO 9001 certified!