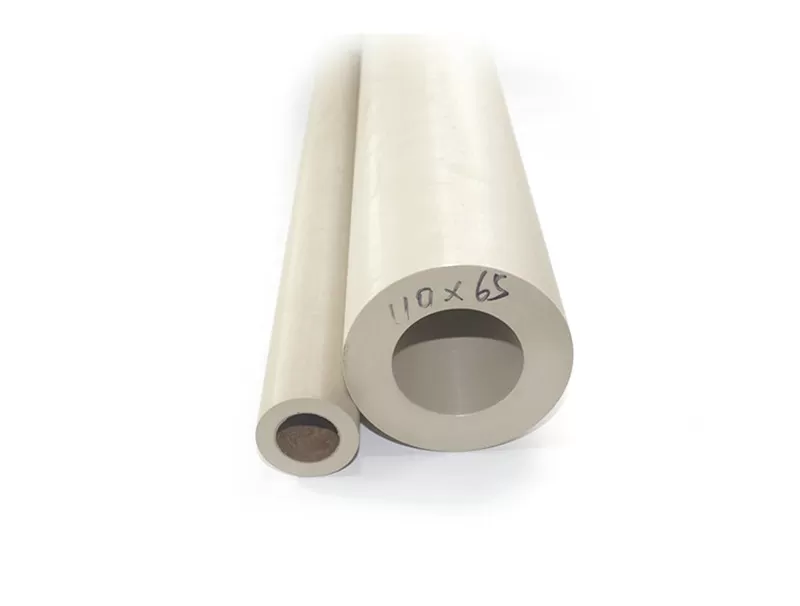

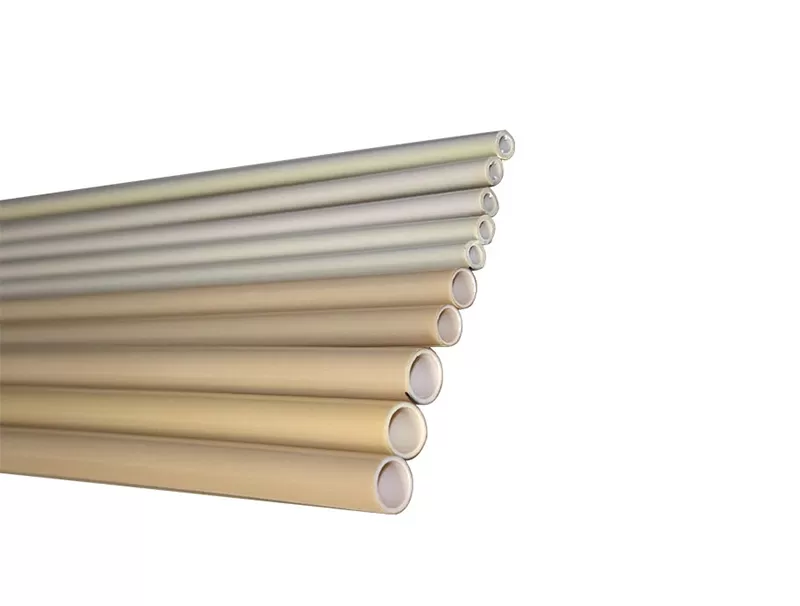

Polyether Ether Ketone Tubes (PEEK) deliver unmatched performance in harsh industrial and medical environments. With exceptional thermal stability (up to 260°C), chemical resistance, and mechanical strength, these tubes are precision-engineered for high-pressure fluid systems, corrosion-prone applications, and biocompatible devices. Available in custom sizes and ARKPEEK® grades (GF30, CF30, MOD, 1000).

_______________________________________________________________________________________________________________________________________________________________________

Polyether Ether Ketone Tubes (PEEK): Engineered for Extreme Reliability

Crafted from advanced ARKPEEK® polymers, our Polyether Ether Ketone Tubes (PEEK) are designed to outperform metals and standard plastics in the most demanding conditions. These tubes combine the intrinsic benefits of PEEK—exceptional thermal, chemical, and mechanical properties—with tailored formulations to meet specialized industrial, medical, and energy sector needs.

Key Advantages

Unmatched Thermal Resistance: Operate continuously at 260°C (500°F) with short-term tolerance up to 310°C—ideal for steam, oil refining, and aerospace exhaust systems.

Chemical Inertness: Resistant to hydrocarbons, acids, solvents, and sour gas, making them perfect for oil/gas pipelines and chemical processing.

Mechanical Durability: High tensile strength (up to 210 MPa with CF30 grade) and low creep deformation under sustained loads.

Biocompatibility: FDA-compliant ARKPEEK-1000® tubes for surgical instruments, implants, and diagnostic devices.

Industry-Specific Solutions

Oil & Gas:

Replace corroded metal tubing in downhole tools, injection systems, and offshore rigs.

MOD-grade tubes reduce friction in hydraulic systems, extending component lifespan.

Aerospace:

GF30 and CF30 tubes for lightweight fuel lines, engine components, and thermal shields.

Medical:

Sterilizable, biocompatible tubing for fluid transfer systems and MRI-compatible devices.

Renewable Energy:

Chemical-resistant tubes for geothermal and hydrogen fuel cell applications.

Customization & Compliance

Tailored Dimensions: Specify OD (10mm–600mm), ID, wall thickness, and length.

Material Grades:

ARKPEEK-1000®: Virgin PEEK for maximum purity (UL94 V-0, FDA).

ARKPEEK-CF30®: Carbon fiber-reinforced for structural rigidity.

ARKPEEK-GF30®: Glass fiber-enhanced for dimensional stability.

ARKPEEK-MOD®: PTFE/graphite/carbon blend for ultra-low friction.

Certifications: ISO 9001, RoHS, REACH, and ISO 13485 (medical).

Technical Specifications

Temperature Range: -70°C to +260°C (continuous).

Pressure Tolerance: Up to 300 bar (dependent on grade/size).

Surface Finish: Ra <0.8µm (standard), electropolished options available.

Electrical Properties: Dielectric strength up to 19 kV/mm (GF30).

Why Partner With Us?

Rapid Prototyping: Free sample cuttings to validate fit and performance.

Bulk Order Efficiency: Volume discounts and just-in-time inventory solutions.

Global Logistics: HS code support, air/sea shipping, and customs documentation.

Transform Your Applications with PEEK Tubes

Whether you’re battling corrosion in offshore drilling or designing life-saving medical devices, our Polyether Ether Ketone Tubes offer a reliable, cost-effective alternative to traditional materials. Request a quote, technical datasheet, or engineering consultation today!

_______________________________________________________________________________________________________________________________________________________________________

Material Grades

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

Polyetheretherketone Tube Size

| NO. | Dimension OD*ID (mm) | Weight ( g ) |

| 1 | ∅1.6*∅0.13*1000 | 2.6 |

| 2 | ∅1.6*∅0.25*1000 | 2.5 |

| 3 | ∅1.6*∅0.5*1000 | 2.4 |

| 4 | ∅1.6*∅0.75*1000 | 2.0 |

| 5 | ∅1.6*∅1*1000 | 1.6 |

| 6 | ∅2.33*∅1.6*1000 | 2.9 |

| 7 | ∅2.8*∅2.5*1000 | 1.6 |

| 8 | ∅3*∅2.67*1000 | 1.9 |

| 9 | ∅3.2*∅1*1000 | 9.4 |

| 10 | ∅3.2*∅1.6*1000 | 7.8 |

| 11 | ∅5*∅2.5*1000 | 19.1 |

| 12 | ∅5*∅4.5*1000 | 5.8 |

| 13 | ∅7.5*∅4*1000 | 42.6 |

| 14 | ∅10.2*∅8*1000 | 40.9 |

| 15 | ∅12*∅4*1000 | 81.6 |

| 16 | ∅12.45*∅8.88*1000 | 77.7 |

| 17 | ∅29*∅18*1000 | 527.6 |

| 18 | ∅39*∅31*1000 | 571.5 |

| 19 | ∅80*∅30*1000 | 5612.8 |

| 20 | ∅90*∅40*1000 | 6633.3 |

| 21 | ∅100*∅50*1000 | 7653.8 |

| 22 | ∅110*∅60*1000 | 8674.3 |

| 23 | ∅130*∅60*1000 | 13572.7 |

| 24 | ∅140*∅80*1000 | 13470.6 |

| 25 | ∅160*∅90*1000 | 17858.8 |

| 26 | ∅168*∅132*1000 | 11021.0 |

| 27 | ∅180*∅110*1000 | 20716.2 |

| 28 | ∅190*∅130*1000 | 19593.6 |

| 29 | ∅190*∅140*1000 | 16838.3 |

| 30 | ∅200*∅130*1000 | 23573.6 |

| 31 | ∅220*∅150*1000 | 26431.0 |

| 32 | ∅240*∅170*1000 | 29288.4 |

| 33 | ∅257*∅230*1000 | 13418.6 |

| 34 | ∅250*∅190*1000 | 26941.0 |

| 35 | ∅260*∅210*1000 | 23981.8 |

| 36 | ∅280*∅210*1000 | 35003.2 |

| 37 | ∅280*∅230*1000 | 26022.0 |

| 38 | ∅300*∅250*1000 | 28063.8 |

| 39 | ∅320*∅300*1000 | 12654.2 |

| 40 | ∅340*∅250*1000 | 54188.6 |

| 41 | ∅360*∅280*1000 | 52249.6 |

| 42 | ∅580*∅450*1000 | 136645.0 |