Machining PEEK

Semi-Finished PEEK Tubes are precision-engineered near-net shape stock, designed to minimize machining effort and material waste. Available in ARKPEEK® grades (GF30, CF30, MOD, 1000), these tubes provide exceptional thermal stability (260°C), chemical resistance, and mechanical strength for aerospace, medical, and industrial applications.

_______________________________________________________________________________________________________________________________________________________________________

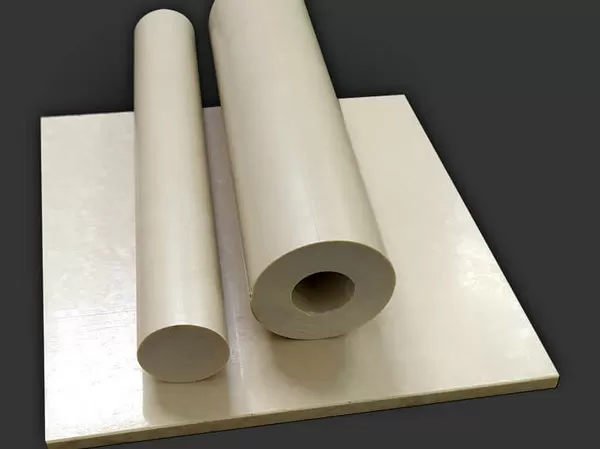

Semi-Finished PEEK Tubes: Optimized for Efficient Precision Machining

Our Semi-Finished PEEK Tubes are pre-processed to near-net dimensions, reducing machining time and costs while maintaining the superior performance of ARKPEEK® materials. Ideal for manufacturers needing high-quality raw stock for valves, bearings, or custom components, these tubes come in four specialized grades to match your application’s demands:

Material Grades & Machining Advantages

ARKPEEK-GF30® (30% Glass Fiber):

High Rigidity & Stability: Minimizes deflection during machining, perfect for tight-tolerance parts like bushings or structural spacers.

Low Moisture Absorption: Ensures dimensional consistency in humid environments.

ARKPEEK-CF30® (30% Carbon Fiber):

Enhanced Strength & Conductivity: Ideal for electrically insulating components or lightweight structural parts.

Superior Surface Finish: Reduces post-machining polishing needs.

ARKPEEK-MOD® (PTFE/Graphite/Carbon):

Ultra-Low Friction: Simplifies machining of dynamic parts like seals or sliders, with minimal tool wear.

Wear Resistance: Extends component lifespan in high-friction environments.

ARKPEEK-1000® (Virgin PEEK):

Chemical Purity: FDA-compliant for medical implants or food-grade applications.

Smooth Machining: Uniform density allows for flawless CNC/lathe processing.

Why Choose Semi-Finished PEEK Tubes?

Cost & Time Savings: Near-net shape reduces material waste and machining hours by up to 30%.

Custom Pre-Processing: Specify OD, ID, wall thickness, and length for seamless integration into your workflow.

Global Compliance: ISO-certified production, RoHS/REACH compliance, and traceable documentation.

Industry Applications

Aerospace: Rapid prototyping of engine components or fuel system parts with GF30/CF30 tubes.

Medical: Machining biocompatible surgical tool blanks from ARKPEEK-1000®.

Oil & Gas: Pre-processed MOD® tubes for corrosion-resistant valve bodies or pump housings.

Automotive: High-strength CF30 stock for sensor housings or transmission components.

Technical Specifications

Standard Sizes: 50mm–1000mm OD | 10mm–900mm ID (customizable).

Key Metrics:

Thermal: Continuous use at 260°C (all grades).

Mechanical: Tensile strength up to 210 MPa (CF30).

Surface Roughness: Ra <1.6µm (as-supplied; further finishing optional).

Order Flexibility

In-Stock Tubes: Fast shipping for popular sizes and grades.

Bulk Discounts: Competitive pricing for large-volume orders.

Prototyping Support: Free sample cuttings to test machinability.

_______________________________________________________________________________________________________________________________________________________________________

Material Grades

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Pipes Size Table

| NO. | Dimension OD*ID (mm) | Weight ( g ) |

| 1 | ∅1.6*∅0.13*1000 | 2.6 |

| 2 | ∅1.6*∅0.25*1000 | 2.5 |

| 3 | ∅1.6*∅0.5*1000 | 2.4 |

| 4 | ∅1.6*∅0.75*1000 | 2.0 |

| 5 | ∅1.6*∅1*1000 | 1.6 |

| 6 | ∅2.33*∅1.6*1000 | 2.9 |

| 7 | ∅2.8*∅2.5*1000 | 1.6 |

| 8 | ∅3*∅2.67*1000 | 1.9 |

| 9 | ∅3.2*∅1*1000 | 9.4 |

| 10 | ∅3.2*∅1.6*1000 | 7.8 |

| 11 | ∅5*∅2.5*1000 | 19.1 |

| 12 | ∅5*∅4.5*1000 | 5.8 |

| 13 | ∅7.5*∅4*1000 | 42.6 |

| 14 | ∅10.2*∅8*1000 | 40.9 |

| 15 | ∅12*∅4*1000 | 81.6 |

| 16 | ∅12.45*∅8.88*1000 | 77.7 |

| 17 | ∅29*∅18*1000 | 527.6 |

| 18 | ∅39*∅31*1000 | 571.5 |

| 19 | ∅80*∅30*1000 | 5612.8 |

| 20 | ∅90*∅40*1000 | 6633.3 |

| 21 | ∅100*∅50*1000 | 7653.8 |

| 22 | ∅110*∅60*1000 | 8674.3 |

| 23 | ∅130*∅60*1000 | 13572.7 |

| 24 | ∅140*∅80*1000 | 13470.6 |

| 25 | ∅160*∅90*1000 | 17858.8 |

| 26 | ∅168*∅132*1000 | 11021.0 |

| 27 | ∅180*∅110*1000 | 20716.2 |

| 28 | ∅190*∅130*1000 | 19593.6 |

| 29 | ∅190*∅140*1000 | 16838.3 |

| 30 | ∅200*∅130*1000 | 23573.6 |

| 31 | ∅220*∅150*1000 | 26431.0 |

| 32 | ∅240*∅170*1000 | 29288.4 |

| 33 | ∅257*∅230*1000 | 13418.6 |

| 34 | ∅250*∅190*1000 | 26941.0 |

| 35 | ∅260*∅210*1000 | 23981.8 |

| 36 | ∅280*∅210*1000 | 35003.2 |

| 37 | ∅280*∅230*1000 | 26022.0 |

| 38 | ∅300*∅250*1000 | 28063.8 |

| 39 | ∅320*∅300*1000 | 12654.2 |

| 40 | ∅340*∅250*1000 | 54188.6 |

| 41 | ∅360*∅280*1000 | 52249.6 |

| 42 | ∅580*∅450*1000 | 136645.0 |