Tube PEEK Polymer

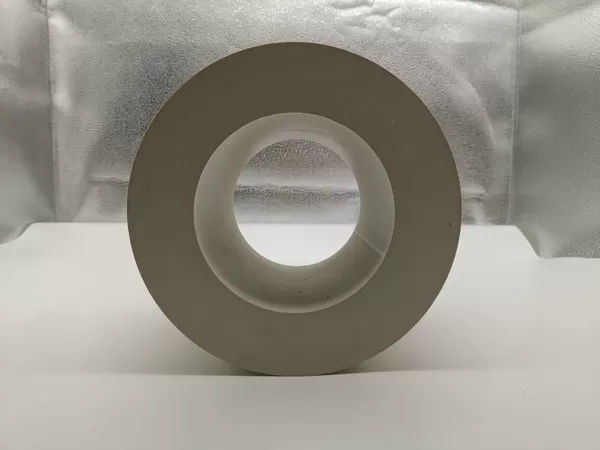

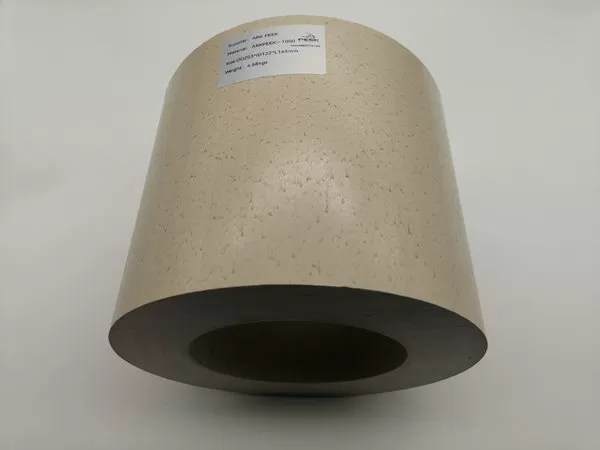

PEEK Tube 203x122mm is engineered for high-stress industrial applications requiring precision machining. This diameter tubes offers exceptional thermal stability (up to 260°C), chemical resistance, and mechanical strength, making it perfect for aerospace, oil/gas, and medical components. Available in-stock or custom sizes. Solve challenges like corrosion, wear, and high-temperature failure—order now or request tailored dimensions.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Tube 203x122mm: Precision Machining Solutions for Industrial Components

Our PEEK Tube 203x122mm exemplifies the superior performance of ARKPEEK® materials, designed for machining into critical parts that demand durability in extreme environments. While 203x122mm is one example size, we offer a wide range of custom PEEK tubing dimensions to meet your specific needs, whether for prototyping or large-scale production.

Why Choose Our PEEK Tubes?

Industrial-Grade Performance:

Thermal Stability: Operates continuously at 260°C (500°F), with short-term resistance up to 310°C.

Chemical Resistance: Withstands acids, hydrocarbons, and steam, ideal for oil/gas and chemical processing.

Machining Precision: Uniform density and low moisture absorption (<0.1%) ensure stability during CNC, turning, or milling.

Flexible Sizing:

In-Stock Sizes: Fast delivery for 203x122mm and other popular dimensions.

Custom Orders: Tailor outer diameter (OD), inner diameter (ID), and wall thickness for unique applications.

Certified Quality: ISO-compliant manufacturing with traceable material grades (ARKPEEK-1000®, CF30®, GF30®, MOD®).

Applications Across Industries

Aerospace: Lightweight, heat-resistant components for engines and fuel systems.

Medical: Biocompatible tubing for surgical instruments and diagnostic devices.

Oil & Gas: Corrosion-resistant valves, seals, and pump parts for harsh environments.

Semiconductors: Ultra-clean, static-free tubing for contamination-sensitive processes.

Key Metrics:

Tensile Strength: 90–210 MPa (grade-dependent).

Flammability Rating: UL94 V-0.

Surface Finish: Smooth or textured options for specific friction needs.

Order with Confidence

Fast Turnaround: In-stock PEEK tube 203x122mm ships within 48 hours.

Custom Solutions: Request prototypes or bulk orders with no minimum quantity.

Global Support: HS code documentation and logistics assistance for seamless imports.

Transform Your Machining Process

Upgrade to ARKPEEK® tubing for components that last longer, perform better, and reduce downtime. Contact us for quotes, samples, or engineering support!

_______________________________________________________________________________________________________________________________________________________________________

Material Options

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Tubes Size Table

| NO. | Dimension OD*ID (mm) | Weight ( g ) |

| 1 | ∅1.6*∅0.13*1000 | 2.6 |

| 2 | ∅1.6*∅0.25*1000 | 2.5 |

| 3 | ∅1.6*∅0.5*1000 | 2.4 |

| 4 | ∅1.6*∅0.75*1000 | 2.0 |

| 5 | ∅1.6*∅1*1000 | 1.6 |

| 6 | ∅2.33*∅1.6*1000 | 2.9 |

| 7 | ∅2.8*∅2.5*1000 | 1.6 |

| 8 | ∅3*∅2.67*1000 | 1.9 |

| 9 | ∅3.2*∅1*1000 | 9.4 |

| 10 | ∅3.2*∅1.6*1000 | 7.8 |

| 11 | ∅5*∅2.5*1000 | 19.1 |

| 12 | ∅5*∅4.5*1000 | 5.8 |

| 13 | ∅7.5*∅4*1000 | 42.6 |

| 14 | ∅10.2*∅8*1000 | 40.9 |

| 15 | ∅12*∅4*1000 | 81.6 |

| 16 | ∅12.45*∅8.88*1000 | 77.7 |

| 17 | ∅29*∅18*1000 | 527.6 |

| 18 | ∅39*∅31*1000 | 571.5 |

| 19 | ∅80*∅30*1000 | 5612.8 |

| 20 | ∅90*∅40*1000 | 6633.3 |

| 21 | ∅100*∅50*1000 | 7653.8 |

| 22 | ∅110*∅60*1000 | 8674.3 |

| 23 | ∅130*∅60*1000 | 13572.7 |

| 24 | ∅140*∅80*1000 | 13470.6 |

| 25 | ∅160*∅90*1000 | 17858.8 |

| 26 | ∅168*∅132*1000 | 11021.0 |

| 27 | ∅180*∅110*1000 | 20716.2 |

| 28 | ∅190*∅130*1000 | 19593.6 |

| 29 | ∅190*∅140*1000 | 16838.3 |

| 30 | ∅200*∅130*1000 | 23573.6 |

| 31 | ∅220*∅150*1000 | 26431.0 |

| 32 | ∅240*∅170*1000 | 29288.4 |

| 33 | ∅257*∅230*1000 | 13418.6 |

| 34 | ∅250*∅190*1000 | 26941.0 |

| 35 | ∅260*∅210*1000 | 23981.8 |

| 36 | ∅280*∅210*1000 | 35003.2 |

| 37 | ∅280*∅230*1000 | 26022.0 |

| 38 | ∅300*∅250*1000 | 28063.8 |

| 39 | ∅320*∅300*1000 | 12654.2 |

| 40 | ∅340*∅250*1000 | 54188.6 |

| 41 | ∅360*∅280*1000 | 52249.6 |

| 42 | ∅580*∅450*1000 | 136645.0 |