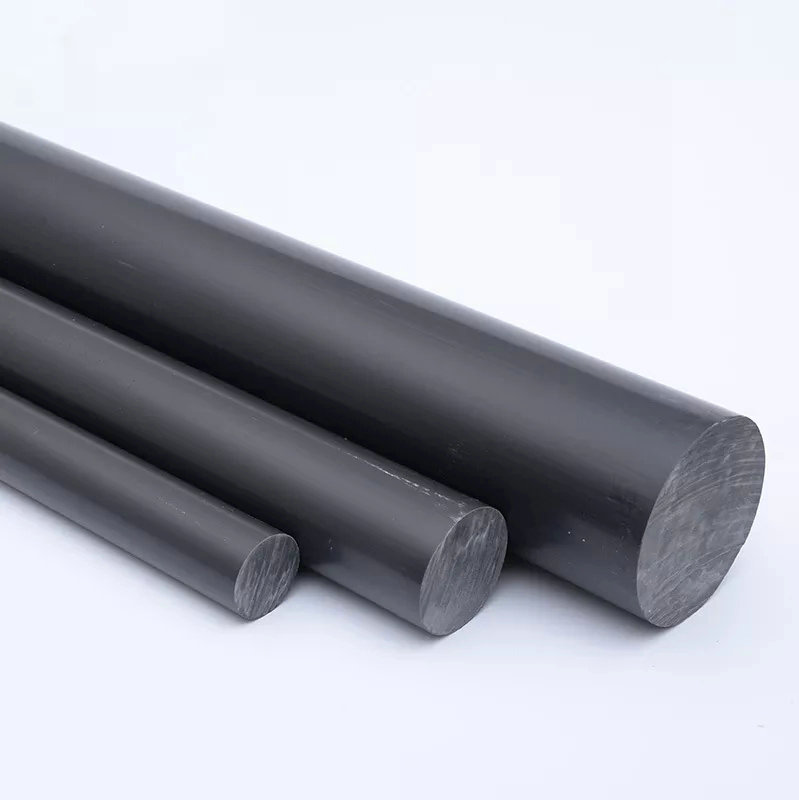

Our Carbon PEEK rods offer superior mechanical strength, wear resistance, and high-temperature stability, making them ideal for demanding applications. Available in various carbon filled PEEK rod sizes, these rods are perfect for industries that require durable materials. Find competitive carbon filled PEEK rod prices and carbon PEEK bars for sale from reliable carbon PEEK rod manufacturers.

_______________________________________________________________________________________________________________________________________________________________________

Carbon PEEK rods are engineered for high-performance applications where strength, wear resistance, and thermal stability are essential. These rods are manufactured from carbon filled PEEK, a material known for its outstanding durability and high mechanical strength, making it an ideal choice for industries such as aerospace, automotive, medical, and manufacturing.

Our carbon PEEK rods come in a range of carbon PEEK rod sizes, allowing for versatility in various projects. Whether you’re looking for a specific diameter or custom sizing, our carbon filled PEEK rod sizes can be tailored to meet your needs. The carbon filled PEEK material properties provide enhanced wear resistance and reduced friction, making these rods ideal for applications such as bearings, seals, and components subject to high stress.

We offer carbon filled PEEK rods for sale, providing you with access to high-quality materials at competitive carbon filled PEEK rod prices. If you're searching for carbon filled PEEK rod manufacturers, we stand out for our commitment to top-tier manufacturing standards, ensuring you receive only the best products.

Whether you’re purchasing a single rod or in bulk, you can rely on us for accurate pricing and fast delivery. Our carbon PEEK bar cost is designed to give you the best value without sacrificing quality. For businesses seeking high-performance materials, we provide cost-effective solutions that help improve the efficiency and longevity of your products.

Find the perfect carbon filled PEEK rod for sale for your project and experience the benefits of carbon PEEK material properties in your applications. From carbon PEEK rod sizes to carbon filled PEEK rod cost, we are your trusted supplier for reliable, durable, and high-performance carbon PEEK rods.

_______________________________________________________________________________________________________________________________________________________________________

Carbon PEEK Rod Sizes

| Number | Rod diameter(mm) | Weight per meter ( g ) | Dimension tolerance mm | |||

| ARKPEEK-1000 | ARKPEEK-CF30 | ARKPEEK-GF30 | ARKPEEK-MOD | |||

| 1 | 5 | 31 | 33 | 34 | 32 | 0~0.2 |

| 2 | 6 | 42 | 46 | 47 | 45 | 0~0.2 |

| 3 | 7 | 55 | 61 | 63 | 59 | 0~0.2 |

| 4 | 8 | 70 | 78 | 80 | 75 | 0~0.2 |

| 5 | 10 | 107 | 119 | 123 | 115 | 0~0.2 |

| 6 | 12 | 152 | 169 | 175 | 163 | 0~0.2 |

| 7 | 15 | 235 | 261 | 270 | 252 | 0~0.2 |

| 8 | 18 | 336 | 374 | 387 | 361 | 0~0.2 |

| 9 | 20 | 413 | 460 | 476 | 445 | 0~0.2 |

| 10 | 22 | 499 | 556 | 575 | 537 | 0~0.2 |

| 11 | 25 | 499 | 556 | 575 | 537 | 0~0.2 |

| 12 | 28 | 663 | 736 | 761 | 712 | 0~0.5 |

| 13 | 30 | 825 | 917 | 948 | 887 | 0~0.5 |

| 14 | 33 | 943 | 1049 | 1085 | 1014 | 0~0.5 |

| 15 | 35 | 1136 | 1265 | 1307 | 1222 | 0~0.5 |

| 16 | 38 | 1275 | 1419 | 1467 | 1371 | 0~0.5 |

| 17 | 40 | 1499 | 1669 | 1725 | 1612 | 0~o.5 |

| 18 | 42 | 1658 | 1846 | 1909 | 1783 | 0~0.5 |

| 19 | 45 | 1825 | 2033 | 2102 | 1964 | 0~1 |

| 20 | 48 | 2102 | 2330 | 2409 | 2250 | 0~1 |

| 21 | 50 | 2386 | 2648 | 2738 | 2557 | 0~1 |

| 22 | 53 | 2586 | 2881 | 2979 | 2783 | 0~1 |

| 23 | 55 | 2902 | 3232 | 3343 | 3122 | 0~1 |

| 24 | 60 | 3122 | 3478 | 3597 | 3359 | 0~1 |

| 25 | 65 | 3699 | 4133 | 4274 | 3991 | 0~1 |

| 26 | 70 | 4317 | 4864 | 5030 | 4698 | 0~2 |

| 27 | 80 | 5055 | 5632 | 5825 | 5440 | 0~2 |

| 28 | 85 | 6586 | 7340 | 7591 | 7089 | 0~2 |

| 29 | 90 | 7428 | 8279 | 8562 | 7995 | 0~2 |

| 30 | 95 | 8321 | 9275 | 9593 | 8957 | 0~2 |

| 31 | 100 | 9265 | 10328 | 10682 | 9973 | 0~2 |

| 32 | 110 | 10260 | 11438 | 11830 | 11045 | 0~2 |

| 33 | 120 | 12403 | 13828 | 14303 | 13353 | 0~2 |

| 34 | 130 | 14750 | 16446 | 17011 | 15881 | 0~2 |

| 35 | 140 | 17301 | 19291 | 19955 | 18628 | 0~3 |

| 36 | 150 | 20057 | 22365 | 23134 | 21595 | 0~3 |

| 37 | 160 | 23016 | 25666 | 26549 | 24783 | 0~3 |

| 38 | 165 | 26180 | 29194 | 30199 | 28189 | 0~3 |

| 39 | 180 | 27838 | 31044 | 32112 | 29975 | 0~3 |

| 40 | 200 | 33149 | 36964 | 38206 | 35663 | 0~3 |

| 41 | 220 | 49477 | 55176 | 57046 | 53247 | 0~3 |

| 42 | 250 | 63866 | 71226 | 73649 | 68743 | 0~3 |