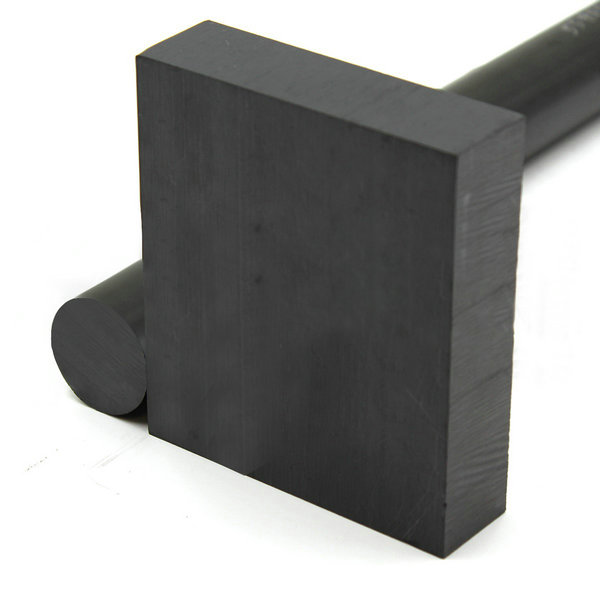

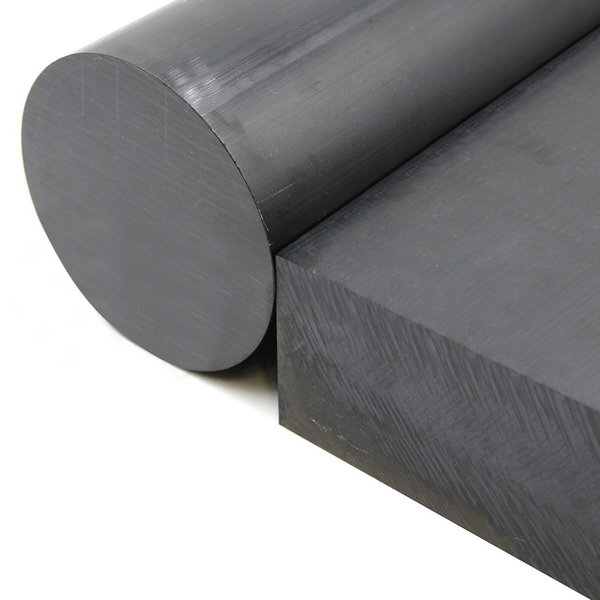

PEEK ESD Material

ESD PEEK stands at the forefront of cutting-edge materials, offering the ultimate electrostatic dissipative solution for industries reliant on sensitive electronic components. This specialized version of PEEK (Polyether Ether Ketone) boasts exceptional properties, including rapid static charge dissipation and precise control over electrostatic risks. From aerospace to semiconductor manufacturing, ESD PEEK ensures enhanced productivity and safety, providing a reliable shield against the damaging effects of electrostatic discharge.

PEEK ESD material is a specialized and highly innovative solution designed to address the critical needs of industries dealing with electrostatic discharge (ESD) risks. This advanced material is a variation of PEEK (Polyether Ether Ketone), a renowned high-performance polymer known for its exceptional mechanical and thermal properties.

In environments where sensitive electronic components are present, electrostatic discharge can lead to costly damage and compromise the overall product quality. However, PEEK ESD material offers a proactive approach to this challenge, providing reliable and precise electrostatic dissipative properties to protect sensitive electronics from the harmful effects of ESD.

Key Features and Benefits of PEEK ESD Material:

1, Electrostatic Dissipative Properties: PEEK ESD material is engineered to have controlled and rapid static charge dissipation capabilities. By effectively neutralizing electrostatic charges, this material ensures that sensitive electronic components remain shielded from potential damage caused by ESD, minimizing the risk of costly failures.

2, Advanced Mechanical Strength: Like standard PEEK, PEEK ESD material retains exceptional mechanical properties, including high tensile strength, stiffness, and wear resistance. This combination of ESD protection and mechanical strength makes it an ideal choice for applications demanding both safety and performance.

3, Chemical and Thermal Stability: PEEK ESD material maintains the excellent chemical resistance and thermal stability associated with standard PEEK. It can withstand a wide range of harsh environments, making it suitable for use in diverse industries.

4, Versatile Applications: PEEK ESD material finds applications in various sectors, including aerospace, automotive, electronics manufacturing, telecommunications, and medical equipment manufacturing. It is a go-to material where sensitive electronic components require reliable and long-term electrostatic protection.

5, Seamless Integration: PEEK ESD material can be processed using standard manufacturing techniques, such as injection molding and machining. This ease of processing allows for seamless integration into existing production processes, making it a convenient choice for industry applications.

In summary, PEEK ESD material is a cutting-edge solution that combines the exceptional properties of standard PEEK with the crucial characteristic of electrostatic dissipation. Its ability to neutralize static charges effectively ensures the safety and reliability of sensitive electronic components, making it an indispensable material in the world of high-tech manufacturing. Embrace the power of PEEK ESD material to elevate your products' performance, protect against ESD risks, and gain a competitive edge in industries where electronics play a vital role.