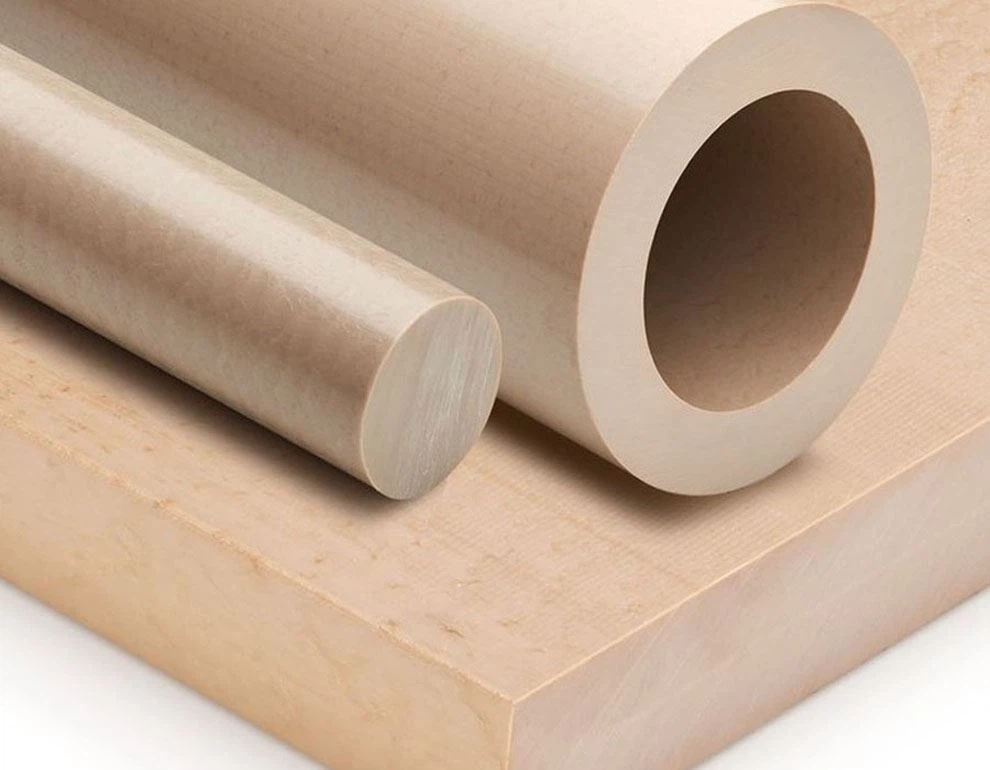

Food Contact PEEK Plastic

PEEK Material Food Grade is a specialized formulation of polyetheretherketone designed for food contact applications. It is FDA compliant, non-toxic, and resistant to high temperatures and chemicals, making it ideal for food processing equipment and packaging materials. This material ensures food safety while providing exceptional mechanical properties and durability.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Material Food Grade is a high-performance thermoplastic engineered specifically for applications requiring direct contact with food products. It meets stringent FDA regulations, ensuring it is safe for use in food processing, packaging, and handling environments. This variant of PEEK is renowned for its exceptional mechanical properties, thermal stability, and chemical resistance, making it a reliable choice for industries where food safety is paramount.

Key Features of PEEK Material Food Grade

Food Safety Compliance: PEEK Material Food Grade is FDA compliant, adhering to 21CFR 177.2415 standards, ensuring it is non-toxic and suitable for direct contact with foodstuffs.

High Temperature Resistance: It can withstand high temperatures, maintaining its integrity during processing and packaging operations.

Chemical Resistance: Resistant to a wide range of chemicals, including cleaning agents used in food processing environments.

Mechanical Properties: Offers high mechanical strength and dimensional stability, crucial for components exposed to static loads over long periods.

Applications and Uses

Food Processing Equipment: Components such as pumps, valves, and fittings benefit from its durability and chemical resistance.

Packaging Materials: Suitable for films and trays due to its non-reactive surface and ability to withstand sterilization processes.

Medical Devices: Its biocompatibility and sterilization capabilities make it suitable for medical applications as well.

Technical Specifications and Compliance

For detailed specifications, please refer to our product documentation. Our PEEK Material Food Grade is designed to meet the highest standards of food safety and performance, addressing concerns about is PEEK food safe and is PEEK plastic food grade by ensuring compliance with regulatory requirements. Whether you're seeking PEEK plastic food grade solutions for your food processing needs or looking to understand how is PEEK food grade materials can enhance your operations, our resources are here to guide you through the selection process.

_______________________________________________________________________________________________________________________________________________________________________

FDA PEEK Grades List

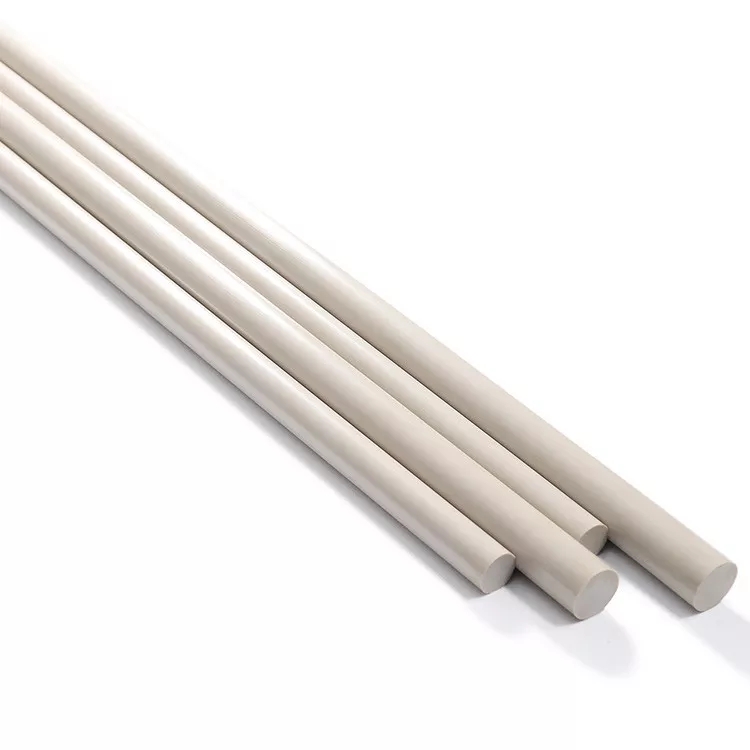

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fibre reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range of PEEK Rod is from -30°C to 250°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

FDA PEEK Rod Size Chart

| Number | Rod diameter(mm) | Weight per meter ( g ) | Dimension tolerance mm | |||

| ARKPEEK-1000 | ARKPEEK-CF30 | ARKPEEK-GF30 | ARKPEEK-MOD | |||

| 1 | 5 | 31 | 33 | 34 | 32 | 0~0.2 |

| 2 | 6 | 42 | 46 | 47 | 45 | 0~0.2 |

| 3 | 7 | 55 | 61 | 63 | 59 | 0~0.2 |

| 4 | 8 | 70 | 78 | 80 | 75 | 0~0.2 |

| 5 | 10 | 107 | 119 | 123 | 115 | 0~0.2 |

| 6 | 12 | 152 | 169 | 175 | 163 | 0~0.2 |

| 7 | 15 | 235 | 261 | 270 | 252 | 0~0.2 |

| 8 | 18 | 336 | 374 | 387 | 361 | 0~0.2 |

| 9 | 20 | 413 | 460 | 476 | 445 | 0~0.2 |

| 10 | 22 | 499 | 556 | 575 | 537 | 0~0.2 |

| 11 | 25 | 499 | 556 | 575 | 537 | 0~0.2 |

| 12 | 28 | 663 | 736 | 761 | 712 | 0~0.5 |

| 13 | 30 | 825 | 917 | 948 | 887 | 0~0.5 |

| 14 | 33 | 943 | 1049 | 1085 | 1014 | 0~0.5 |

| 15 | 35 | 1136 | 1265 | 1307 | 1222 | 0~0.5 |

| 16 | 38 | 1275 | 1419 | 1467 | 1371 | 0~0.5 |

| 17 | 40 | 1499 | 1669 | 1725 | 1612 | 0~o.5 |

| 18 | 42 | 1658 | 1846 | 1909 | 1783 | 0~0.5 |

| 19 | 45 | 1825 | 2033 | 2102 | 1964 | 0~1 |

| 20 | 48 | 2102 | 2330 | 2409 | 2250 | 0~1 |

| 21 | 50 | 2386 | 2648 | 2738 | 2557 | 0~1 |

| 22 | 53 | 2586 | 2881 | 2979 | 2783 | 0~1 |

| 23 | 55 | 2902 | 3232 | 3343 | 3122 | 0~1 |

| 24 | 60 | 3122 | 3478 | 3597 | 3359 | 0~1 |

| 25 | 65 | 3699 | 4133 | 4274 | 3991 | 0~1 |

| 26 | 70 | 4317 | 4864 | 5030 | 4698 | 0~2 |

| 27 | 80 | 5055 | 5632 | 5825 | 5440 | 0~2 |

| 28 | 85 | 6586 | 7340 | 7591 | 7089 | 0~2 |

| 29 | 90 | 7428 | 8279 | 8562 | 7995 | 0~2 |

| 30 | 95 | 8321 | 9275 | 9593 | 8957 | 0~2 |

| 31 | 100 | 9265 | 10328 | 10682 | 9973 | 0~2 |

| 32 | 110 | 10260 | 11438 | 11830 | 11045 | 0~2 |

| 33 | 120 | 12403 | 13828 | 14303 | 13353 | 0~2 |

| 34 | 130 | 14750 | 16446 | 17011 | 15881 | 0~2 |

| 35 | 140 | 17301 | 19291 | 19955 | 18628 | 0~3 |

| 36 | 150 | 20057 | 22365 | 23134 | 21595 | 0~3 |

| 37 | 160 | 23016 | 25666 | 26549 | 24783 | 0~3 |

| 38 | 165 | 26180 | 29194 | 30199 | 28189 | 0~3 |

| 39 | 180 | 27838 | 31044 | 32112 | 29975 | 0~3 |

| 40 | 200 | 33149 | 36964 | 38206 | 35663 | 0~3 |

| 41 | 220 | 49477 | 55176 | 57046 | 53247 | 0~3 |

| 42 | 250 | 63866 | 71226 | 73649 | 68743 | 0~3 |