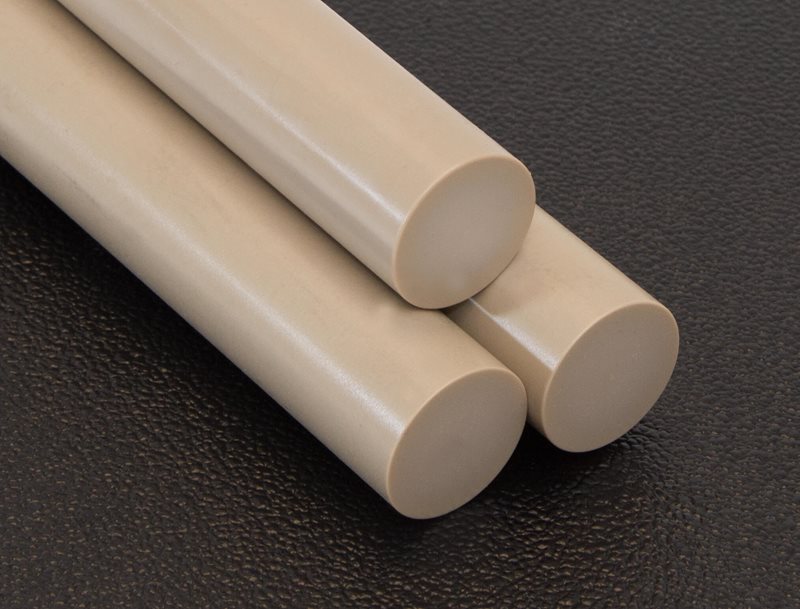

Explore our premium PEEK GF30 glass filled rods, engineered for superior performance in demanding industrial applications. These rods are reinforced with 30% glass fibers, enhancing their mechanical strength, stiffness, and dimensional stability. Available in a variety of sizes, our PEEK GF30 rods provide effective solutions for engineers and manufacturers seeking reliable materials.

_______________________________________________________________________________________________________________________________________________________________________

Introducing our PEEK GF30 glass filled rods, a superior choice for engineers and manufacturers seeking enhanced performance in demanding applications. These rods are engineered from high-quality Polyether Ether Ketone (PEEK) reinforced with 30% glass fibers, delivering exceptional mechanical strength and thermal stability that surpasses traditional PEEK materials.

The incorporation of glass fibers into the PEEK matrix significantly improves the material's rigidity and dimensional stability, making it ideal for applications that require high load-bearing capabilities and resistance to deformation under stress. This makes our PEEK GF30 rods particularly suitable for industries such as aerospace, automotive, and medical devices, where reliability and performance are paramount.

Our PEEK GF30 glass filled rod sizes are available in a variety of dimensions to meet diverse project specifications. Whether you need small diameters for intricate components or larger sizes for structural applications, we offer a comprehensive selection to suit your needs.

In addition to their robust physical properties, these rods exhibit excellent chemical resistance, allowing them to perform reliably in harsh environments and with aggressive media. This versatility makes them an ideal choice for applications requiring both strength and resilience.

Understanding the PEEK GF30 glass filled rod price is essential for effective project budgeting. We offer competitive pricing that reflects the quality and performance of our products. Our transparent pricing structure ensures you can easily assess the glass peek rod price based on your specific requirements.

For those looking to purchase glass peek rods for sale, we provide a user-friendly ordering experience with detailed product information readily available. Our commitment to quality assurance and customer satisfaction positions us as a trusted supplier in the industry.

To further assist you in making informed decisions, we offer a comprehensive PEEK GF30 datasheet that outlines the technical specifications, mechanical properties, and recommended applications of our glass-filled rods. This resource is invaluable for engineers seeking to optimize their designs or troubleshoot existing challenges.

Elevate your projects with our PEEK GF30 glass filled rods, where superior performance meets reliability. Contact us today to learn more about our offerings or to discuss your specific needs regarding 30 glass peek rod cost or availability. Let us be your partner in achieving engineering excellence.

_______________________________________________________________________________________________________________________________________________________________________

Glass PEEK Rod Sizes

| Number | Rod diameter(mm) | Weight per meter ( g ) | Dimension tolerance mm | |||

| ARKPEEK-1000 | ARKPEEK-CF30 | ARKPEEK-GF30 | ARKPEEK-MOD | |||

| 1 | 5 | 31 | 33 | 34 | 32 | 0~0.2 |

| 2 | 6 | 42 | 46 | 47 | 45 | 0~0.2 |

| 3 | 7 | 55 | 61 | 63 | 59 | 0~0.2 |

| 4 | 8 | 70 | 78 | 80 | 75 | 0~0.2 |

| 5 | 10 | 107 | 119 | 123 | 115 | 0~0.2 |

| 6 | 12 | 152 | 169 | 175 | 163 | 0~0.2 |

| 7 | 15 | 235 | 261 | 270 | 252 | 0~0.2 |

| 8 | 18 | 336 | 374 | 387 | 361 | 0~0.2 |

| 9 | 20 | 413 | 460 | 476 | 445 | 0~0.2 |

| 10 | 22 | 499 | 556 | 575 | 537 | 0~0.2 |

| 11 | 25 | 499 | 556 | 575 | 537 | 0~0.2 |

| 12 | 28 | 663 | 736 | 761 | 712 | 0~0.5 |

| 13 | 30 | 825 | 917 | 948 | 887 | 0~0.5 |

| 14 | 33 | 943 | 1049 | 1085 | 1014 | 0~0.5 |

| 15 | 35 | 1136 | 1265 | 1307 | 1222 | 0~0.5 |

| 16 | 38 | 1275 | 1419 | 1467 | 1371 | 0~0.5 |

| 17 | 40 | 1499 | 1669 | 1725 | 1612 | 0~o.5 |

| 18 | 42 | 1658 | 1846 | 1909 | 1783 | 0~0.5 |

| 19 | 45 | 1825 | 2033 | 2102 | 1964 | 0~1 |

| 20 | 48 | 2102 | 2330 | 2409 | 2250 | 0~1 |

| 21 | 50 | 2386 | 2648 | 2738 | 2557 | 0~1 |

| 22 | 53 | 2586 | 2881 | 2979 | 2783 | 0~1 |

| 23 | 55 | 2902 | 3232 | 3343 | 3122 | 0~1 |

| 24 | 60 | 3122 | 3478 | 3597 | 3359 | 0~1 |

| 25 | 65 | 3699 | 4133 | 4274 | 3991 | 0~1 |

| 26 | 70 | 4317 | 4864 | 5030 | 4698 | 0~2 |

| 27 | 80 | 5055 | 5632 | 5825 | 5440 | 0~2 |

| 28 | 85 | 6586 | 7340 | 7591 | 7089 | 0~2 |

| 29 | 90 | 7428 | 8279 | 8562 | 7995 | 0~2 |

| 30 | 95 | 8321 | 9275 | 9593 | 8957 | 0~2 |

| 31 | 100 | 9265 | 10328 | 10682 | 9973 | 0~2 |

| 32 | 110 | 10260 | 11438 | 11830 | 11045 | 0~2 |

| 33 | 120 | 12403 | 13828 | 14303 | 13353 | 0~2 |

| 34 | 130 | 14750 | 16446 | 17011 | 15881 | 0~2 |

| 35 | 140 | 17301 | 19291 | 19955 | 18628 | 0~3 |

| 36 | 150 | 20057 | 22365 | 23134 | 21595 | 0~3 |

| 37 | 160 | 23016 | 25666 | 26549 | 24783 | 0~3 |

| 38 | 165 | 26180 | 29194 | 30199 | 28189 | 0~3 |

| 39 | 180 | 27838 | 31044 | 32112 | 29975 | 0~3 |

| 40 | 200 | 33149 | 36964 | 38206 | 35663 | 0~3 |

| 41 | 220 | 49477 | 55176 | 57046 | 53247 | 0~3 |

| 42 | 250 | 63866 | 71226 | 73649 | 68743 | 0~3 |