Unlock the Potential of Thermoplastic Polymer PEEK

PEEK is a high-performance thermoplastic polymer known for its excellent mechanical and thermal properties. With a chemical formula of C19H12O3, PEEK offers superior resistance to chemicals and high temperatures, making it ideal for demanding applications. Explore its uses and pricing to find the perfect solution for your needs.

_______________________________________________________________________________________________________________________________________________________________________

Thermoplastic Polymer PEEK (Polyether Ether Ketone) is a versatile and high-performance polymer known for its superior mechanical properties, chemical resistance, and exceptional thermal stability. As one of the most advanced thermoplastic materials available, Polymer PEEK is ideal for industries such as aerospace, automotive, medical, and industrial manufacturing, where reliability and durability are critical.

Thermoplastic Polymer PEEK Properties:

High Mechanical Strength: Thermoplastic polymer PEEK maintains outstanding strength even in high-stress conditions, ensuring durability and long-term performance.

Thermal Stability: Withstanding temperatures up to 250°C, PEEK retains its structural integrity and performance even in extreme heat.

Chemical Resistance: PEEK offers superior resistance to chemicals, oils, and solvents, making it suitable for harsh environments where other materials may degrade.

Low Wear and Friction: The low friction and wear properties of Polymer PEEK make it an excellent choice for applications like bearings, seals, and moving components that experience continuous friction.

Polymer PEEK Chemical Formula

The Polymer PEEK formula is based on a polyether ether ketone backbone that gives it its strength, heat resistance, and chemical stability. The chemical formula of PEEK polymer is:

C19H12O3

This unique structure is responsible for its impressive performance across various applications.

Polymer PEEK Ether Ketone

Polymer PEEK Ether Ketone refers to the polymer's chemical structure, where the ether (–O–) and ketone (–C=O) groups alternate in the polymer backbone. This structure enhances its mechanical properties, making PEEK ideal for high-performance applications in aerospace, automotive, and medical industries.

Polymer PEEK Uses:

Due to its exceptional properties, Polymer PEEK is widely used across numerous industries for demanding applications:

Aerospace: Used in critical components such as engine parts, seals, and connectors that require high strength and heat resistance.

Medical Devices: PEEK is biocompatible and used in spinal implants, dental devices, and other surgical instruments.

Automotive: Polymer PEEK is used in seals, gaskets, and other components that must withstand high temperatures and mechanical stress.

Industrial Manufacturing: PEEK is ideal for bearings, seals, gaskets, and electrical insulations that need to perform under extreme conditions.

Thermoplastic Polymer PEEK Price:

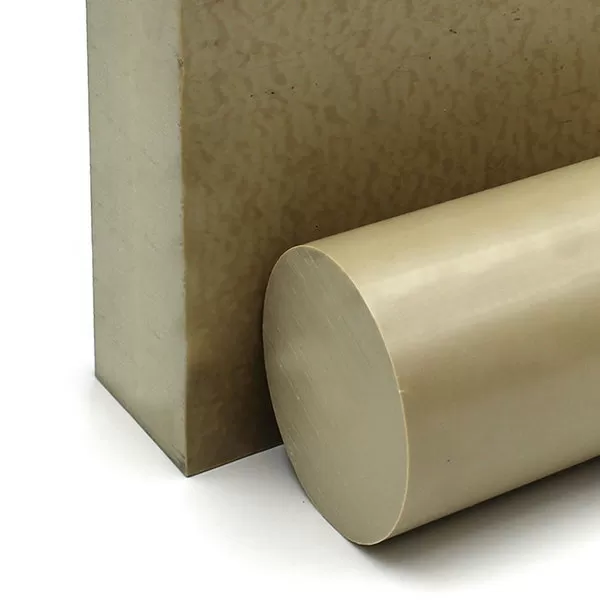

We offer Thermoplastic polymer PEEK for sale in a variety of forms including pellets, rods, sheets, and pipes. The Thermoplastic polymer PEEK price ranges from $40-70 USD/kg, with prices varying based on the form and quantity ordered. Whether you require PEEK polymer in pellets for molding or pre-formed shapes like rod, sheet, or pipe, we offer competitive pricing for both bulk and smaller orders.

As a leading supplier of Thermoplastic polymer PEEK, we ensure that our pricing is designed to provide both value and high-quality materials for your specific needs. Whether you're looking to purchase Polymer PEEK for a specific engineering project or require a reliable supply for large-scale manufacturing, we have you covered.

_______________________________________________________________________________________________________________________________________________________________________

Polymer PEEK Grades

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fibre reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range of PEEK Rod is from -30°C to 250°C and has a short term maximum service temperature of 310°C.