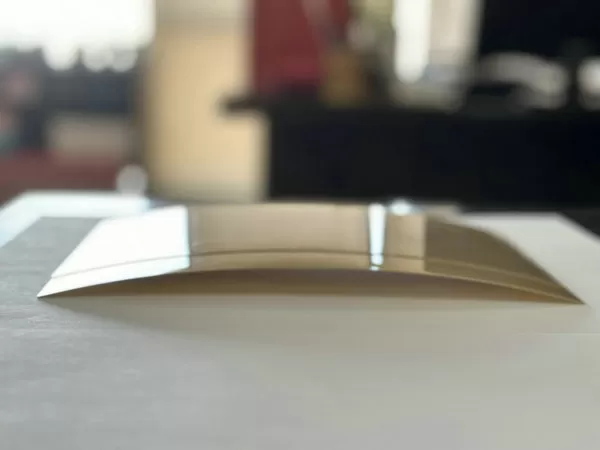

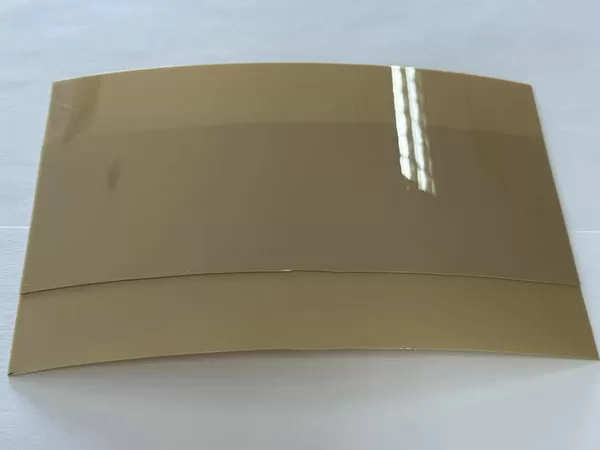

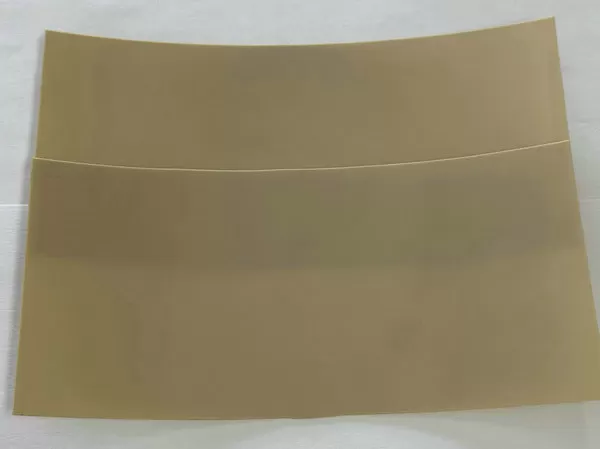

This high-performance material boasts exceptional mechanical strength, chemical resistance, and thermal stability, making it the ideal choice for precision engineering and complex component manufacturing. Lightweight yet durable, our PEEK sheet excels in high-temperature environments and offers excellent electrical insulation properties.

Unlock the potential of high-performance engineering with our 0.5mm PEEK (Polyether Ether Ketone) sheet. This advanced material is designed to meet the rigorous demands of both industrial and medical applications, offering a unique combination of strength, durability, and versatility. The 0.5mm thickness strikes the perfect balance between lightweight and robust, ensuring it can be used in a variety of critical applications where precision and reliability are paramount.

Key Features and Benefits:

1, Exceptional Mechanical Strength: Our 0.5mm PEEK sheet delivers superior tensile strength and rigidity, making it ideal for components subjected to mechanical stress and high loads.

2, Chemical Resistance: PEEK is renowned for its resistance to a wide range of chemicals, including acids, bases, and organic solvents, ensuring longevity and reliability in harsh environments.

3, Thermal Stability: Capable of withstanding high temperatures without compromising its mechanical properties, our PEEK sheet is perfect for applications involving extreme heat.

4, Electrical Insulation: With excellent dielectric properties, PEEK is an ideal material for insulating electrical and electronic components.

5, Biocompatibility: PEEK's biocompatible nature and resistance to sterilization processes make it suitable for medical implants and devices, ensuring patient safety and product reliability.

6, Dimensional Stability: The low thermal expansion and high dimensional stability of PEEK ensure precise and consistent performance in precision engineering applications.

7, Low Friction and Wear Resistance: PEEK's inherent low friction and high wear resistance make it perfect for use in seals, bearings, and other mechanical parts where long-term durability is required.

Applications:

1, Medical Devices: Ideal for fabricating implants, surgical instruments, and other medical components that require biocompatibility and sterilization resistance.

2, Aerospace and Automotive: Used in the production of lightweight, high-strength components that can withstand extreme temperatures and mechanical stress.

3, Electrical and Electronics: Perfect for insulating materials in high-performance electrical and electronic applications due to its excellent dielectric properties.

4, Chemical Processing: Suitable for parts exposed to aggressive chemicals, ensuring durability and performance in demanding environments.

5, Precision Engineering: Essential for creating precision components that demand high dimensional stability and mechanical strength.

6, Seals and Bearings: Utilized in manufacturing low friction, high wear-resistant mechanical parts that ensure long-term reliability and performance.

Choosing our 0.5mm PEEK sheet means investing in a material that offers unmatched performance across a wide range of applications. Its combination of strength, chemical resistance, thermal stability, and biocompatibility makes it an invaluable asset in advanced engineering and medical fields. Whether you’re developing cutting-edge technology or high-performance industrial components, our PEEK sheet is the reliable choice for exceptional quality and longevity.