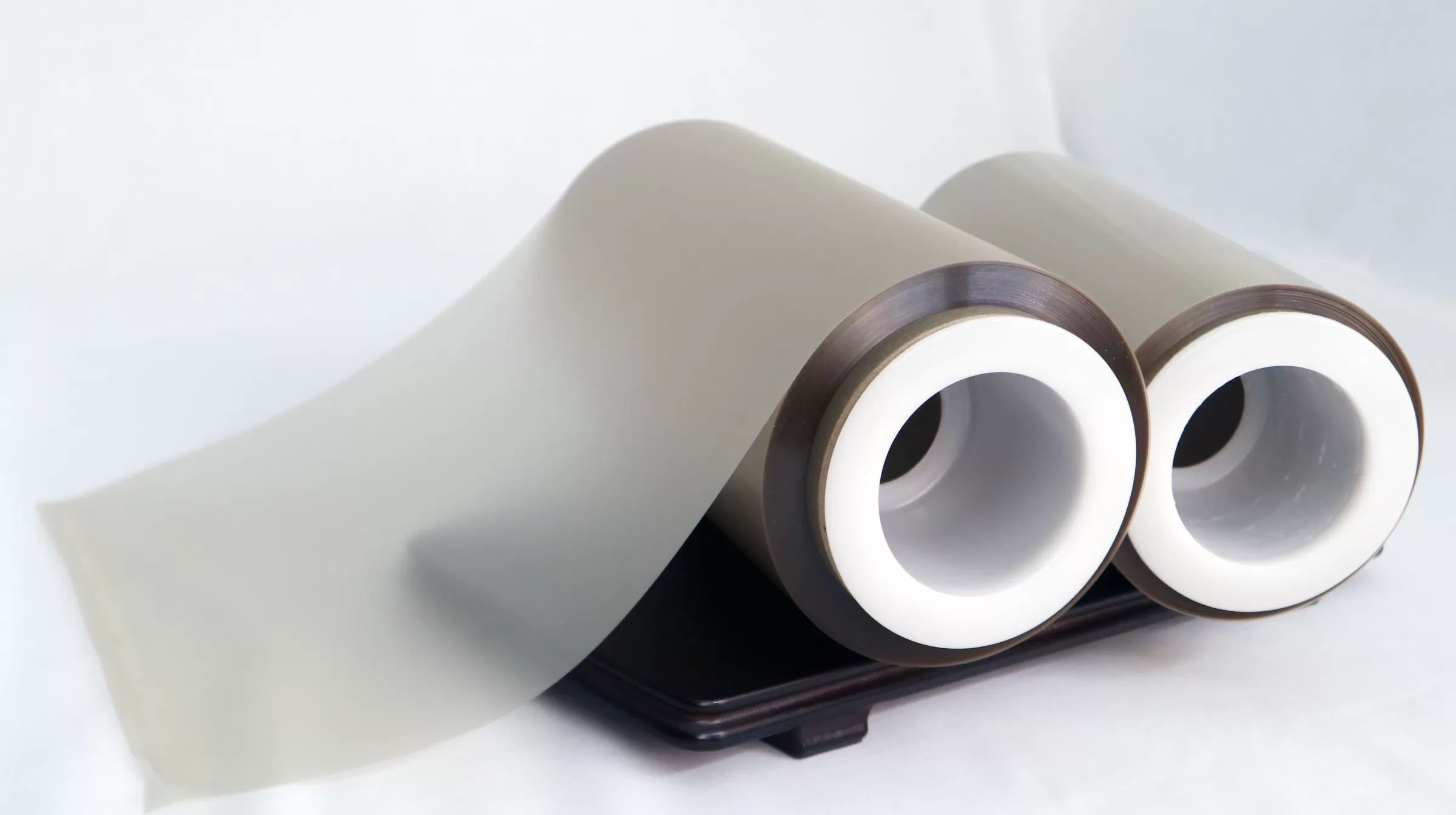

OVERVIEW of PEEK Film

Discover the power of PEEK film in the electronics industry. With exceptional thermal, mechanical, and electrical properties, PEEK film provides reliable insulation, protection, and durability for flexible PCBs, displays, touchscreens, and more. Its resistance to high temperatures, chemicals, and fire, combined with excellent dimensional stability, make it an ideal choice for demanding electronics applications. Experience the reliability and performance of PEEK film in the world of electronics.

FEATURES, BENEFITS and APPLICATIONS of PEEK Film

Material: Amorphous, Semi-crystalline and Mineral Filled Semi-crystalline.

PEEK (polyetheretherketone) Film Provides:

● High Temperature Performance

● Excellent Tribological Properties

● Broad Chemical Resistance

● High-Strength & Toughness

● Electrical Stability & Radiation Resistance

● Low Smoke & Toxic Gas Emission

● High-Purity, extremely low extractables

Applications:

● Micro speaker diaphragm, dome tweeter.

● Presslire exchanger and senior oliaphragin.

● Aerospace high-speed rail insulation and TAB heat insulation components.

● Thrust washers for micro motors, gaskets for automobiles.

● High-temperature resistant label, pressure sensitive tape substrate.

● Insulation layer of electric vehicle battery.

● Flexible film surface heater.

● Wire, cable, insulation and wrcop sheaths.

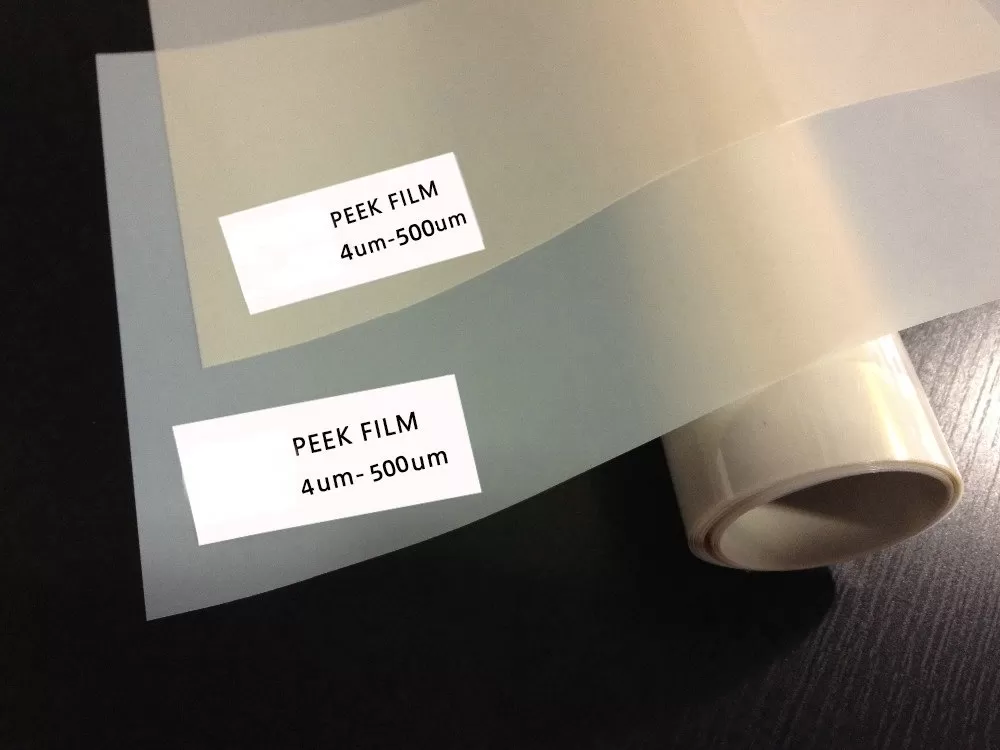

Size

Thicknesses between 10µm (0,01 mm) up to 1000µm (1 mm);

Width usually about 420, 650, 1100mm, but customer preferences of special sizes or thicknesses will be provided.